A quick breaking device for agglomerated paint

A technology of crushing device and paint, applied in grain processing and other directions, can solve the problems of low crushing efficiency, non-existence, poor crushing effect, etc., and achieve the effect of increasing crushing efficiency, ingenious structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

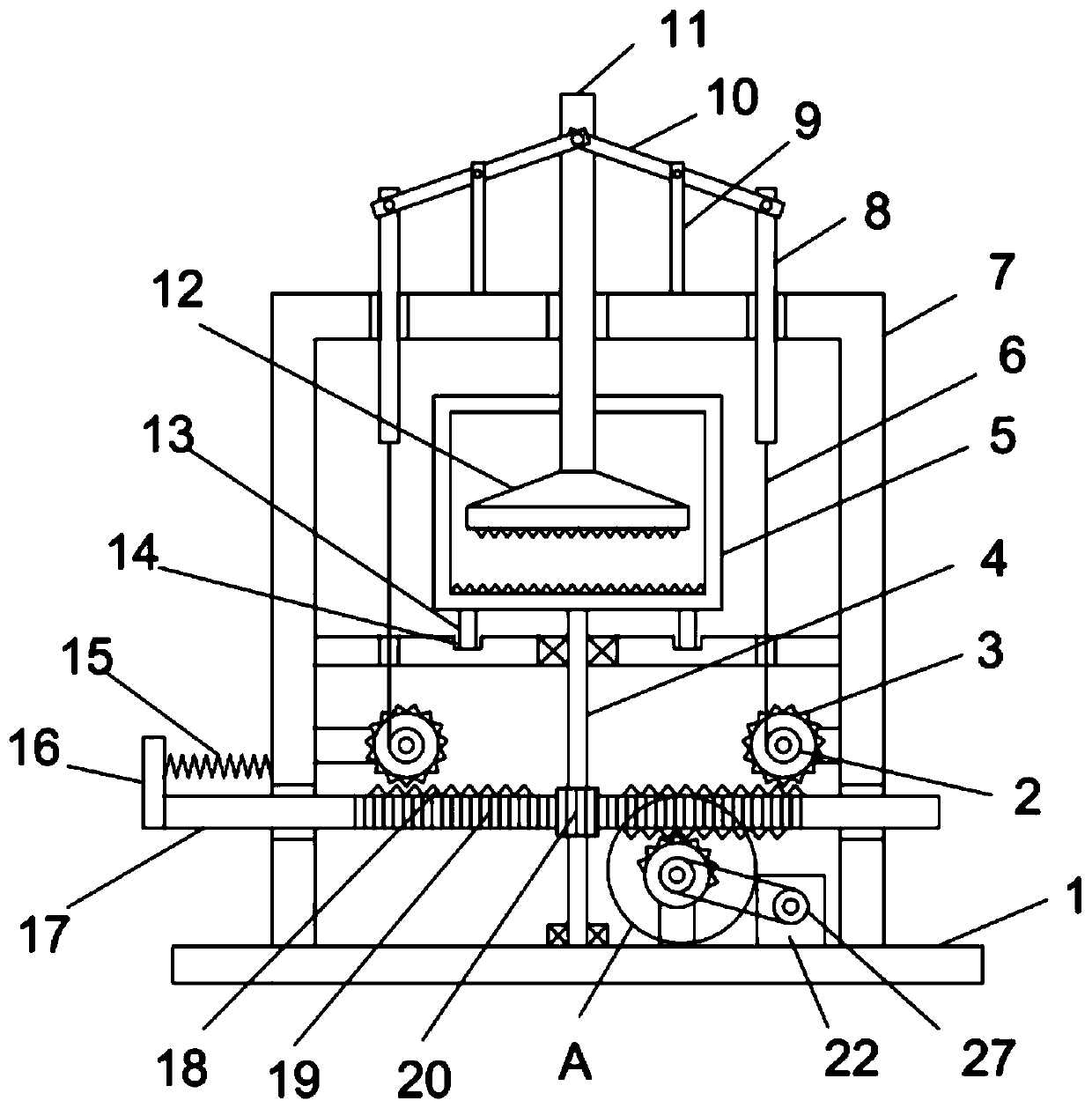

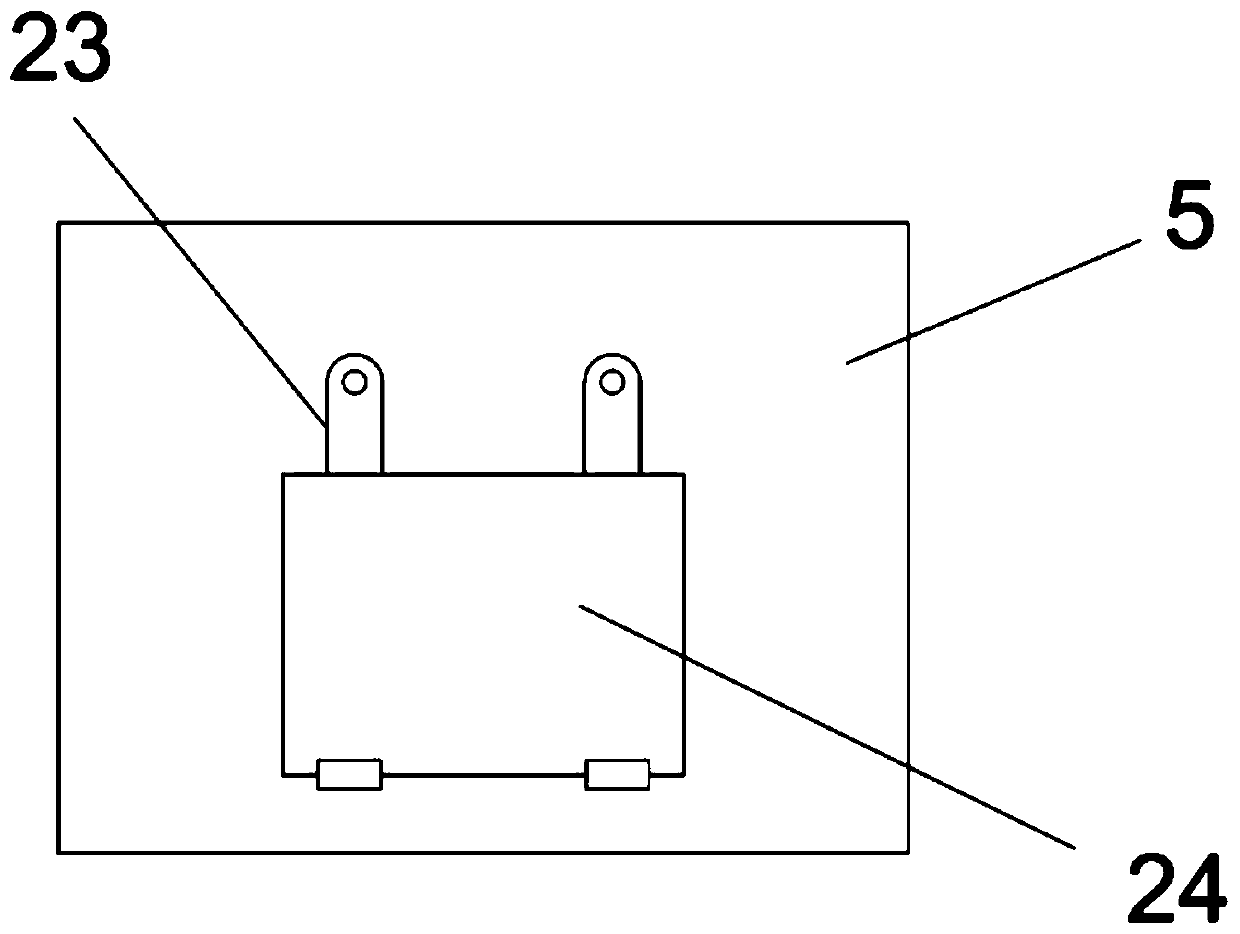

[0020] see Figure 1-4 , a kind of agglomerated paint rapid crushing device, comprising a support frame 7 fixedly installed on the bottom plate 1, a horizontal plate is fixedly installed horizontally in the support frame 7, a crushing mechanism is installed on the horizontal plate, and the crushing mechanism includes a crushing box 5 The bottom of the crushing box 5 is evenly fixed with a number of crushing sawtooths. The vertical sliding type of the crushing box 5 is provided with an impact rod 11. The bottom of the impact rod 11 is horizontally fixed with a crushing pressure plate 12. The impact rod 11 vertically penetrates Support frame 7; said support frame 7 is provided with a transmission assembly, said transmission assembly includes a support rod 9 vertically fixedly installed on the top of the support frame 7, and the support rod 9 is rotatably provided with a rotating rod 10, said rotating rod One end of 10 is hinged on the side wall of the impact rod 11, and the lowe...

Embodiment 2

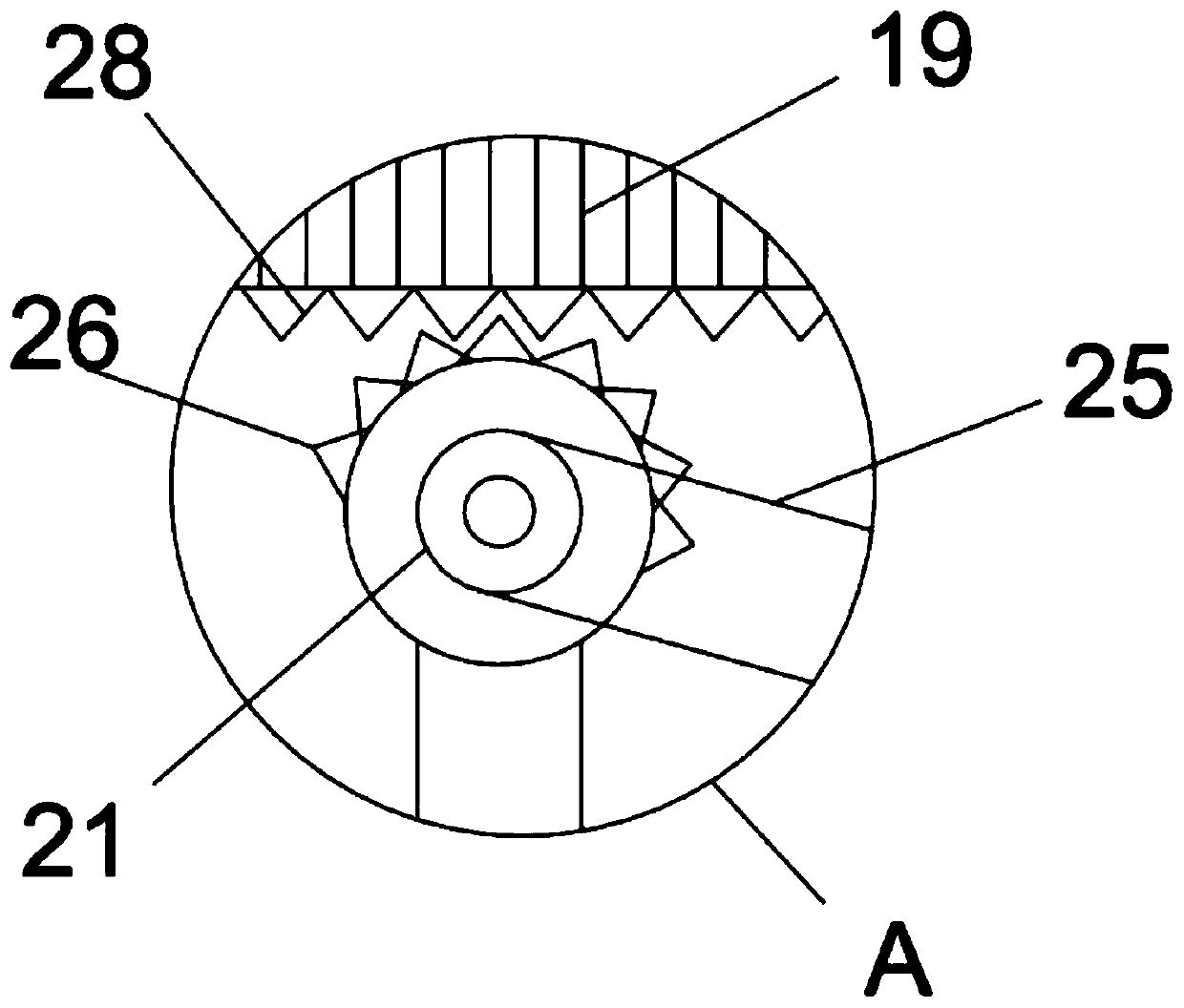

[0024] On the basis of Embodiment 1, in addition, the surface of the rotating shaft 4 is sleeved with a cylindrical spur gear 20 meshed with the side rack 19; Rotate counterclockwise alternately, and then realize that the rotating shaft 4 drives the crushing box 5 to rotate clockwise and counterclockwise alternately, and the relative rotation of the crushing platen 12 and the crushing box 5 realizes the crushing action of the crushing platen 12 on the agglomerated paint in the crushing box 5, Greatly increases the breakage of caked paint.

Embodiment 3

[0026] On the basis of Embodiment 2, in addition, the bottom of the crushing box 5 is fixedly equipped with a guide column 13, and the horizontal plate is provided with an annular limit groove 14, and the guide column 13 is slidably embedded in the annular limit groove 14. 5. When the rotating shaft 4 rotates, the guide post 13 slides along the annular limiting groove 14 to realize the guiding and limiting effect on the crushing box 5, increasing the stability of the crushing box 5 rotation and the process of crushing the paint block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com