Uio-66 in-situ immobilized carboxyl functionalized ionic liquid composite material as well as preparation and application thereof

A technology of carboxyl functionalization and uio-66, which is applied in the preparation of organic compounds, carboxylic acid ester preparation, catalytic reactions, etc., can solve the problems of macromolecular substance adsorption and poor catalytic effect, and achieve good physical and chemical stability properties, fast mass transfer rate, and obvious adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

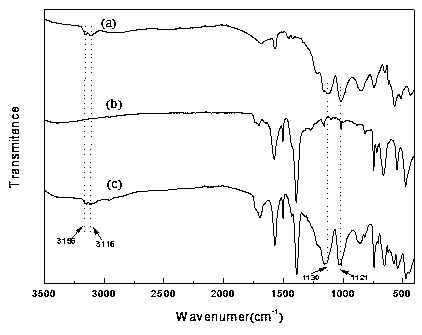

Image

Examples

Embodiment 1

[0022] (1) Preparation of monocarboxyl functionalized ionic liquid

[0023] Accurately weigh 0.1mol of chloroacetic acid and add it to a 100ml round-bottomed flask, add 0.1mol of 1-methylimidazole dropwise under mechanical stirring, react at 70°C for 8 hours, wash with ethanol and dry in vacuum to obtain a white solid Dissolve this white solid in a small amount of deionized water, add sulfuric acid of the same amount, stir magnetically at 70°C for 8 hours, wash with ethyl acetate, and dry in vacuo to obtain 1-carboxymethyl-3-methyl Imidazolium bisulfate;

[0024] (2) Preparation of in situ immobilized monocarboxyl functionalized IL@Uio-66

[0025] Accurately weigh 0.0603g of terephthalic acid in 42ml of DMF, then quickly add 0.0848g of zirconium chloride, ultrasonicate for 30min, add 0.15g of the 1-carboxymethyl-3-methylimidazolium bisulfate synthesized above, and ultrasonicate for 30min , placed in 100ml polytetrafluoroethylene liner, reacted at 120°C for 24h, centrifuged a...

Embodiment 2

[0027] (1) Preparation of dicarboxyl functionalized ionic liquid

[0028] Accurately weigh 0.1mol of 1-methylimidazole and add it to a 100ml round-bottomed flask, add an appropriate amount of bromosuccinic acid dissolved in methanol drop by drop under the condition of mechanical stirring, react at 80°C for 8 hours, and distill under reduced pressure , ethyl acetate, and vacuum-dried to obtain an orange-yellow viscous liquid; dissolve the orange-yellow viscous liquid in a small amount of deionized water, add the same amount of sulfuric acid, and stir magnetically at 70°C for 8 hours. After washing with ethyl ester and vacuum drying, 1-bromo-1,2-dicarboxyethyl-3-methylimidazolium bisulfate was obtained;

[0029] (2) Preparation of in situ immobilized dicarboxyl functionalized IL@Uio-66

[0030] Accurately weigh 0.0603g of terephthalic acid into 42ml of DMF, then quickly add 0.0848g of zirconium chloride, sonicate for 30min, add 0.15g of 1-bromo-1,2-dicarboxyethyl-3-methylimidaz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com