Preparation method and application of derivative catalyst based on LDH fixed transition MOF

A transition metal and catalyst technology, applied in the field of catalysts, can solve the problems of low exposure of active centers, limited catalytic activity, large mass transfer resistance, etc., and achieve the effects of simple preparation method, high catalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

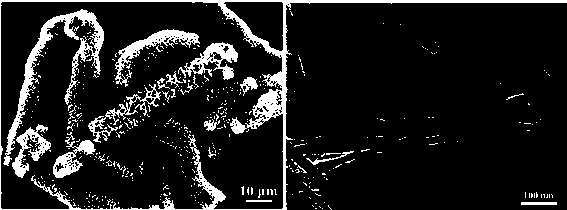

[0034] a) Al 2 o 3 Fiber preparation: Soak 1.88 g of absorbent cotton fibers into 150 mL of 0.1 M Al 2 (SO 4 ) 3 In the aqueous solution, after ultrasonication for 4 h, the soaked absorbent cotton fibers were washed with deionized water to remove excess metal ions on the surface. Al 2 o 3 fiber.

[0035] b) Preparation of ZnAl-LDH carrier with fibrous micro-nano hierarchical structure: Zn(NO 3 ) 2 ∙6H 2 O (0.05 M) and hexamethylenetetramine (0.10 M) were dissolved in 25 mL of deionized water. Then 0.083 g of Al prepared in step a) 2 o 3 The fibers were added to the above solution, stirred at room temperature for 30 min, then transferred to a reactor, reacted at 70 °C for 8 h, centrifuged, washed with water and ethanol three times, and dried at 40 °C for 12 h to obtain a ZnAl-LDH carrier with a hierarchical structure.

[0036] c) Preparation of ZnAl-LDH / Co-MOF composite: Disperse 0.075 g of the ZnAl-LDH carrier prepared in step b) in 30 mL of trimesic acid (1.0 M)...

Embodiment 2

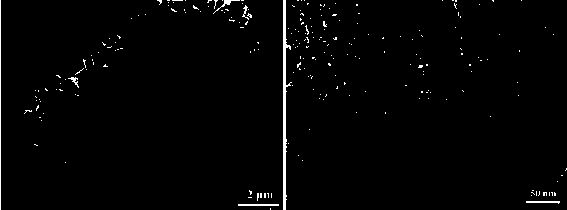

[0040] a) Al 2 o 3 Fiber preparation: 2.50 g of absorbent cotton fibers were soaked in 150 mL of 0.13 M Al(NO 3 ) 3 ∙9H 2 In O aqueous solution, after ultrasonication for 4 h, the soaked absorbent cotton fibers were washed with deionized water to remove excess metal ions on the surface. Al 2 o 3 fiber.

[0041] b) Preparation of CuAl-LDH support with fibrous micro-nano hierarchical structure: Cu(NO 3 ) 2 ∙3H 2 O (0.06 M) and hexamethylenetetramine (0.12 M) were dissolved in 25 mL of deionized water. Then 0.089 g of the Al prepared in step a) 2 o 3 The fibers were added to the above solution, stirred at room temperature for 30 min, then transferred to a reaction kettle, reacted at 120 °C for 10 h, centrifuged, washed with water and ethanol three times, and dried at 60 °C for 12 h to obtain a CuAl-LDH carrier with a hierarchical structure.

[0042] c) Preparation of CuAl-LDH / Co-MOF composite: Disperse 0.086 g of the CuAl-LDH carrier prepared in step b) in 30 mL of ...

Embodiment 3

[0046] a) Al 2 o 3 Fiber preparation: 3.75 g of absorbent cotton fibers were soaked in 150 mL of 0.15 M Al(NO 3 ) 3 ∙9H 2 In O aqueous solution, after ultrasonication for 4 h, the soaked absorbent cotton fibers were washed with deionized water to remove excess metal ions on the surface. Al 2 o 3 fiber.

[0047] b) Preparation of NiAl-LDH support with fibrous micro-nano hierarchical structure: Ni(CH 3 COO) 2 ・4H 2 O (0.07 M) and hexamethylenetetramine (0.14 M) were dissolved in 25 mL of deionized water. Then 0.096 g of the Al prepared in step a) 2 o 3 The fibers were added to the above solution, stirred at room temperature for 30 min, then transferred to a reactor, reacted at 110 °C for 10 h, centrifuged, washed with water and ethanol three times, and dried at 80 °C for 12 h to obtain a NiAl-LDH carrier with a hierarchical structure.

[0048] c) Preparation of NiAl-LDH / Ni-MOF composite: Disperse 0.12 g of the NiAl-LDH carrier prepared in step b) in 30 mL of trimes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com