Preparation method of visible-light nano composite photocatalyst AgCl-SnO2

A nano-composite, photocatalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of reducing catalyst activity and stability, improve the efficiency of visible light catalytic degradation, improve uniformity Dispersion and stability improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1:

[0026] Then add 0.2 mol / L AgNO 3 Solution 20mL, add 0.5 mol / L NH dropwise 3 ·H 2 O until the solution is just transparent, forming liquid sol A; weigh 0.6g of SnCl 4 ·5H 2 O and 0.05g of CTAC were added to 10 mL of 0.01mol / L dilute hydrochloric acid solution, stirred and mixed to obtain mixed solution B; then under stirring, mixed solution B was added dropwise to liquid sol A, and continued stirring for 1 hour to make both Mix uniformly; then, pour the mixture into a 200mL autoclave lined with polytetrafluoroethylene, keep it for 12 hours at 180℃, and then cool to room temperature naturally; finally take out the mixture containing white precipitate, centrifuge it, and wash with distilled water 2 times, and then washed with ethanol once, and the precipitate was vacuum dried at 60°C for 6 hours to obtain visible light catalytically active AgCl-SnO 2 Nano composite photocatalyst.

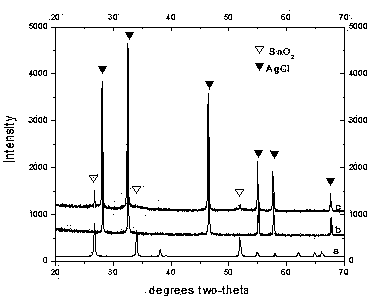

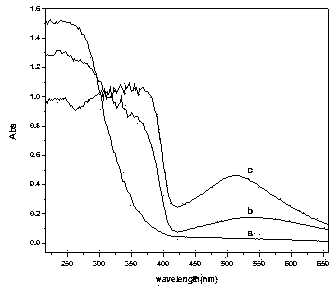

[0027] figure 1 The scanning electron microscope SEM images of the composite catal...

Example Embodiment

[0031] Example 2:

[0032] In order to test AgCl and SnO 2 The effect of different ratios on the photocatalytic activity of the sample. In addition to the different ratios of the two, other reaction conditions such as: CTAC amount (0.05g), reaction temperature (180°C), reaction time (12 hours), calcination time (2 hours) ), AgNO 3 The concentration (0.2 mol / L) and so on are exactly the same as in Example 1. The results show that when AgCl accounts for AgCl and SnO 2 When the molar amount is 70%, the prepared AgCl-SnO 2 The composite material has the best photocatalytic activity. The results show that the conduction band position of AgCl is higher than that of SnO 2 In the photocatalytic reaction, the photogenerated electrons on the AgCl conduction band will be transferred to the SnO 2 The transfer on the conduction band reduces the recombination rate of photo-generated electrons and holes, and improves the catalytic degradation efficiency of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com