Silicon-based composite anode material for lithium ion battery, preparation method thereof, and lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc. capacity attenuation and other issues, to achieve the effect of favorable exchange, high energy density, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

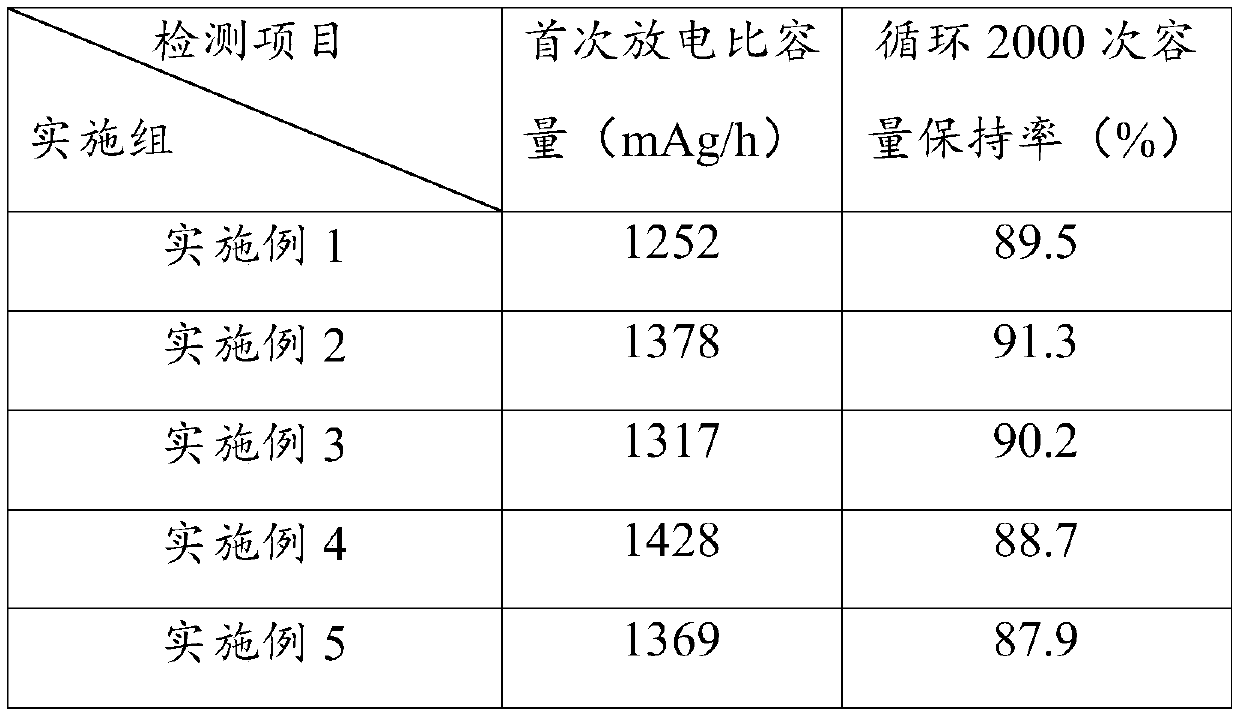

Examples

Embodiment 1

[0046] A preparation method for a silicon-based composite negative electrode material for a lithium ion battery, comprising the following steps:

[0047] (1) Preparation of metal-organosilicon framework materials:

[0048] Add 0.15 mol of silver nitrate, 1 mol of silicon dioxide and 0.6 mol of dihydroxytartaric acid into the reaction kettle, add an aqueous solution of NaOH, mix well, stir and react the mixture at 80°C for 14 hours, and use the obtained reaction product with After washing with ethanol several times, the metal-organosilicon framework material was obtained by drying.

[0049] (2) Preparation of silicon-based composite anode material precursor

[0050] Mix the above metal-organosilicon framework material with 1.5mol silicon-tin alloy particles (with a particle size of 500nm) uniformly to obtain a silicon-based composite negative electrode material precursor.

[0051] (3) Sintering:

[0052] The precursor obtained in step (2) was placed in a tube furnace under a...

Embodiment 2

[0055] The silicon-based composite negative electrode material of this example was prepared in the same manner as in Example 1, except that 0.05 mol of aluminum nitrate was added in step (1).

Embodiment 3

[0057] A preparation method for a silicon-based composite negative electrode material for a lithium ion battery, comprising the following steps:

[0058] (1) Preparation of metal-organosilicon framework materials:

[0059] Add 0.12 mol of zinc chloride, 1 mol of tetraethyl orthosilicate and 1 mol of 2,4 dihydroxybenzoic acid and triethylamine into the reaction kettle, mix evenly, and stir the mixture at 100°C for 12 hours. The obtained reaction product was washed with ethanol several times, and then dried to obtain the metal-organosilicon framework material.

[0060] (2) Preparation of silicon-based composite anode material precursor:

[0061] Mix the metal-organosilicon framework material with 0.8 mol of silicon nanoparticles (particle diameter D50 is 30nm) to obtain a silicon-based composite negative electrode material precursor.

[0062] (3) Sintering:

[0063] The precursor obtained in step (2) was placed in a tube furnace under a nitrogen protective atmosphere, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com