Manganese oxide modified vanadium-based catalyst for denitrifying diesel vehicle tail gas as well as preparation method and application thereof

A manganese oxide and catalyst technology, which is applied in the field of manganese oxide modified vanadium-based catalyst and its preparation, can solve problems such as inability to meet national emission requirements, and achieve the effects of easy control, simple process and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

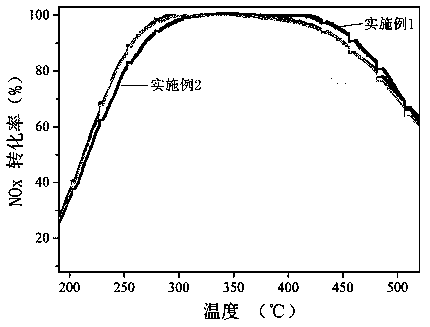

Embodiment 1

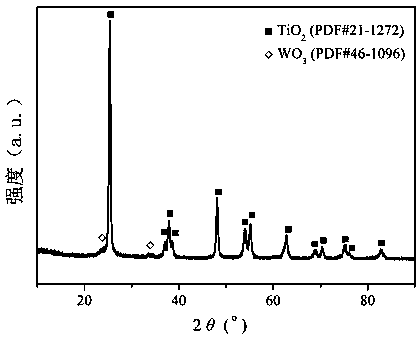

[0044] This example provides a manganese oxide modified vanadium-based catalyst V for denitrification of diesel vehicle exhaust 2 o 5 -WO 3 -MnO x / TiO 2 -1, prepared by the following preparation method.

[0045] Preparation V 2 o 5 -WO 3 -MnO x / TiO 2 -1: (1) the carrier TiO 2 Baking in air atmosphere at 300~400°C for 3~5 hours to remove moisture and impurity gases in the catalyst pores. Take a certain amount of ammonium metavanadate and ammonium metatungstate, add oxalic acid solution with a concentration of 0.1~0.5 mol / L, and stir until they are completely dissolved. Using the equal volume impregnation method, the carrier TiO pretreated by step 2Add to the solution prepared in the above steps, stir for 0.5 hours, dry naturally, and then dry at 60-80°C for 8-12 hours. Calcining the dried powder in an air atmosphere at 400-600°C for 2-5 hours to obtain a vanadium-based catalyst. (2) Using the equal-volume impregnation method, add the obtained vanadium-based catal...

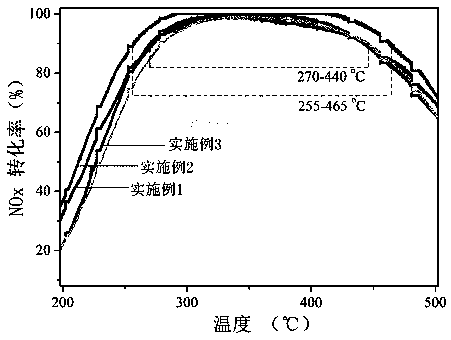

Embodiment 2

[0047] This example provides a manganese oxide modified vanadium-based catalyst V for denitrification of diesel vehicle exhaust 2 o 5 -WO 3 -MnO x / TiO 2 , prepared by the following preparation method.

[0048] The vanadium-based catalyst was prepared by step (1) in Example 1, and the obtained vanadium-based catalyst was added to the manganese (III) acetylacetonate solution dissolved in acetone by an equal-volume impregnation method, stirred for 10 minutes, and dried naturally. Dry at 60~80℃ for 8~12 hours. The dried powder was calcined in an air atmosphere at 550° C. for 4 hours to obtain a manganese oxide-modified vanadium-based catalyst. Among them, the active ingredient V 2 o 5 The mass percentage of the catalyst is 3%, and the auxiliary agent WO 3 The mass percentage of the catalyst is 10%, MnO x The mass percentage of the catalyst is 0.03%, and the carrier TiO 2 The mass percentage of the catalyst is about 86.97%.

Embodiment 3

[0050] This example provides a manganese oxide modified vanadium-based catalyst V for denitrification of diesel vehicle exhaust 2 o 5 -WO 3 -MnO x / TiO 2 , prepared by the following preparation method.

[0051] The vanadium-based catalyst was prepared by step (1) in Example 1, and the obtained vanadium-based catalyst was added to the manganese (III) acetylacetonate solution dissolved in acetone by an equal-volume impregnation method, stirred for 10 minutes, and dried naturally. Dry at 60~80℃ for 8~12 hours. The dried powder was calcined in an air atmosphere at 550° C. for 4 hours to obtain a manganese oxide-modified vanadium-based catalyst. Among them, the active ingredient V 2 o 5 The mass percentage of the catalyst is 3%, and the auxiliary agent WO 3 The mass percentage of the catalyst is 10%, MnO x The mass percentage of the catalyst is 0.08%, and the carrier TiO 2 The mass percentage of the catalyst is about 86.92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com