Homogenous PN (positive-negative) junction on basis of two-dimensional semiconductor materials and method for preparing homogenous PN junction

A two-dimensional semiconductor, semiconductor technology, applied in the field of nanoelectronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

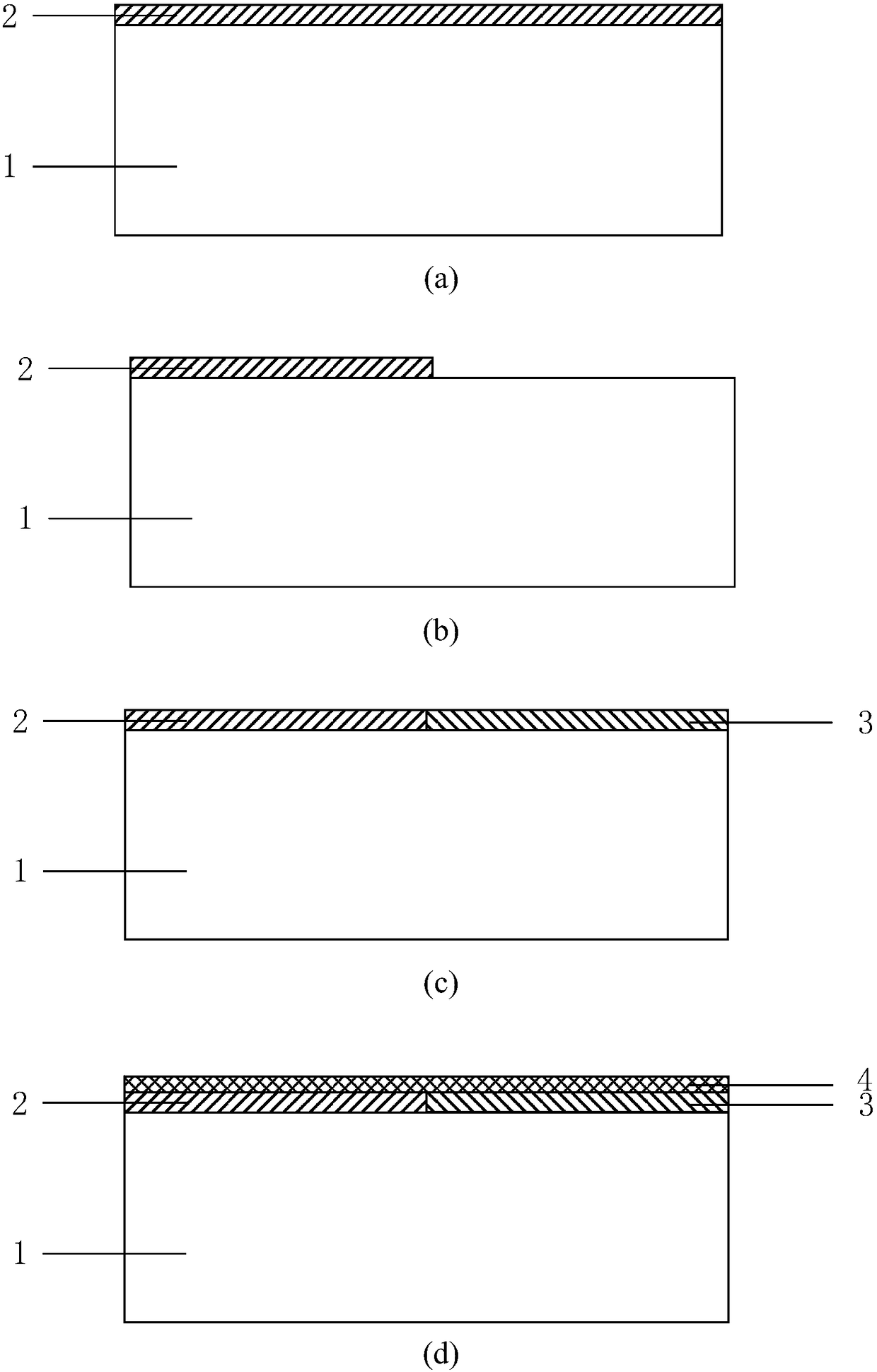

[0036] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

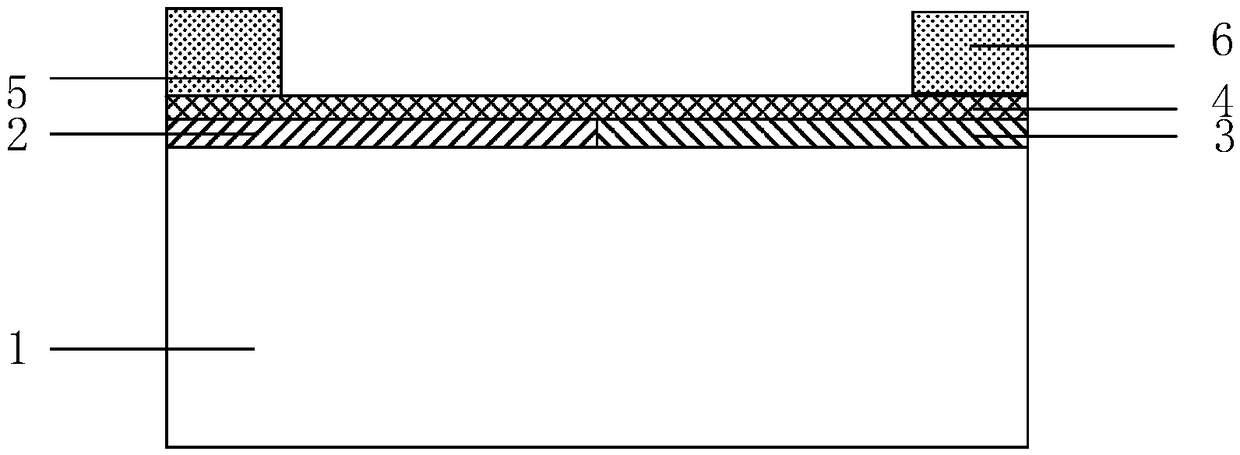

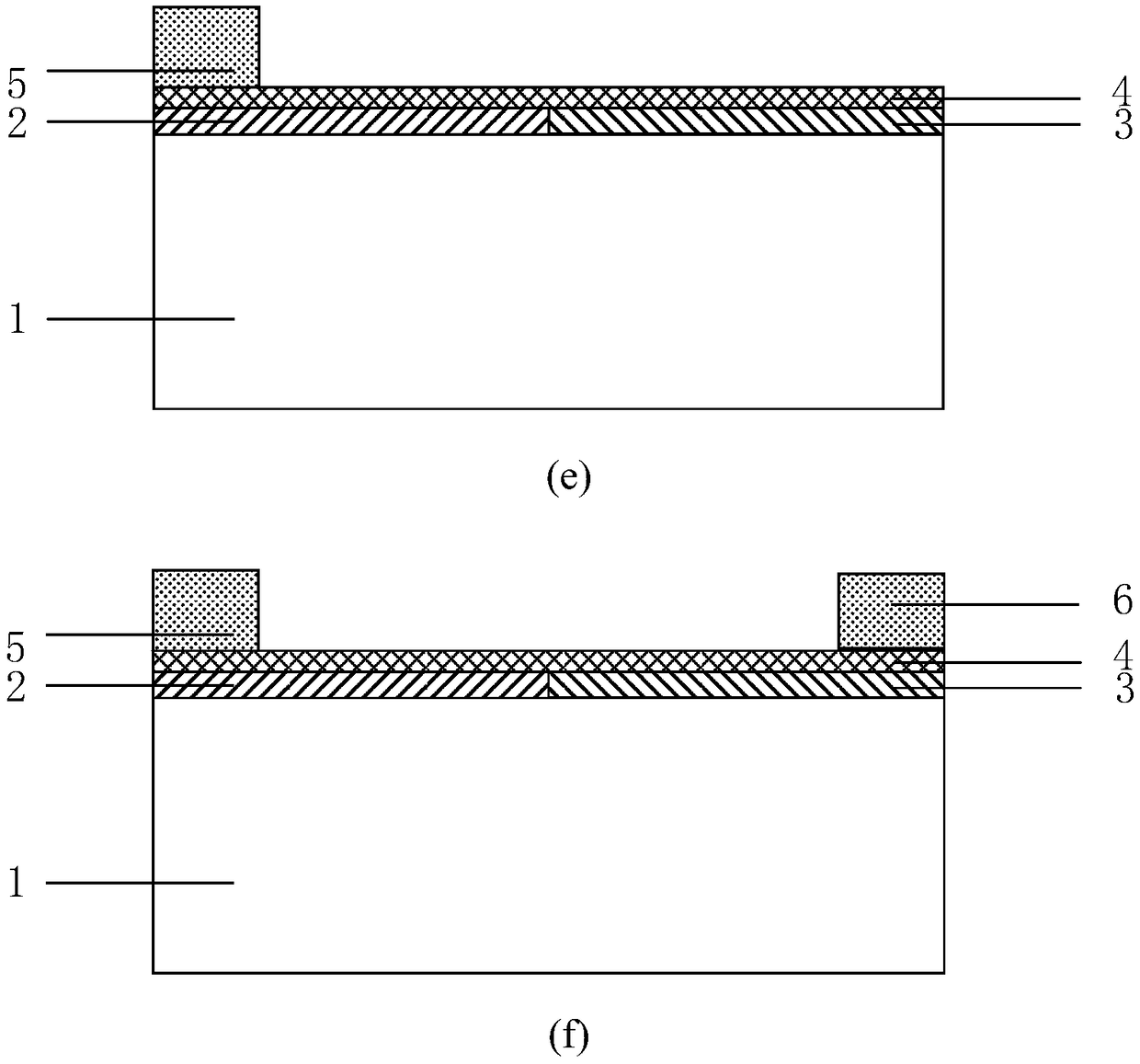

[0037] like figure 1As shown, the prepared homogeneous PN junction based on two-dimensional semiconductor materials includes an insulating substrate 1, a first two-dimensional semiconductor material 2, a second two-dimensional semiconductor material 3, a third two-dimensional semiconductor material 4, and a P-type region metal Contact electrode 5 and N-type regional metal contact electrode 6 . Wherein, the first two-dimensional semiconductor material 2 and the second two-dimensional semiconductor material 3 are located on the insulating substrate 1, the third two-dimensional semiconductor material 4 is located above the first two-dimensional semiconductor material 2 and the second two-dimensional semiconductor material 3, P The type region metal contact electrode 5 and the N type region metal contact electrode 6 are respectively located on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com