Core-shell structure quantum dot with transition layer, fabrication method and application of core-shell structure quantum dot, photoanode, solar photo-electro-chemical device and application of solar photo-electro-chemical device

A core-shell structure, quantum dot technology, applied in capacitors, photovoltaic power generation, electrical components and other directions, can solve the problems of reduced phosgene conversion efficiency, easy oxidation of quantum dots, and reduced photoelectron density, etc., to improve the conversion efficiency of optical devices, The effect of improving the conversion efficiency and service life, and broadening the range of the absorption spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

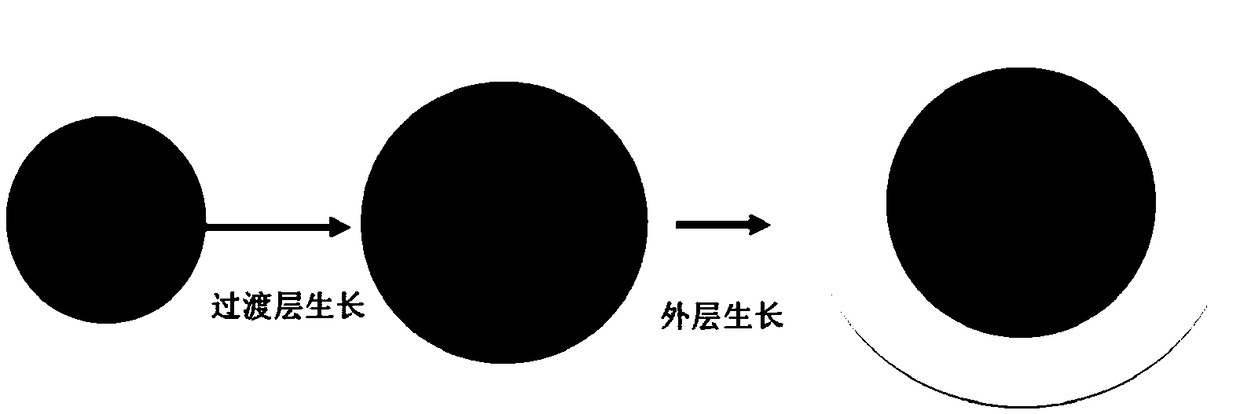

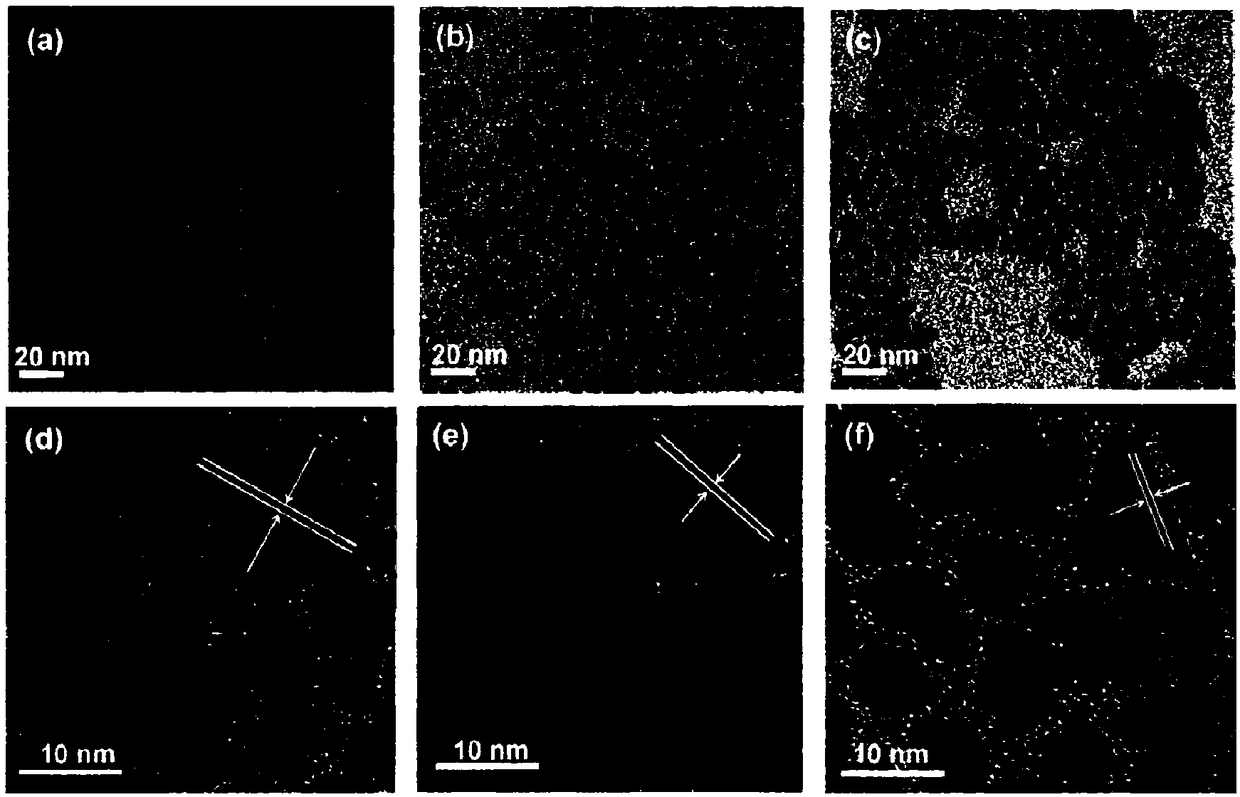

[0070] In a second aspect, in at least one embodiment, a method for preparing a core-shell structure quantum dot with a transition layer is provided, including: first preparing a quantum dot core layer; and then preparing a core-shell structure by an optional ion exchange method Quantum dots; using the method of monolayer atomic layer growth, at a temperature higher than the quantum dots of the core-shell structure, respectively injecting precursors containing Cd ions and S / Se ions to prepare a transition layer; finally using The Cd and S precursors realize the growth of the outermost layer, and the core-shell structure quantum dots of the core layer / transition layer / shell structure are prepared.

[0071] It should be noted that the "preparation of quantum dots with a core-shell structure by an optional ion exchange method" means that after the core layer is prepared, quantum dots with a core-shell structure can be prepared by ion exchange, and then The transition layer is pre...

Embodiment 1

[0123] A core-shell quantum dot with a transition layer, the structure of which is CdSe / 5CdSe x S 1-x / CdS;

[0124] The preparation method comprises the following steps:

[0125] The quantum dot core CdSe was prepared first, and then the quantum dot core CdSe ethane solution (concentration of 2 × 10 -7 mol), oleylamine (5mL) and octadecene (ODE, 5mL) were added into the reaction vessel, after exhaust treatment, it was kept at 100°C for 1h; 0.2M), reacted for 1.5h, then added S powder-Se powder / ODE (0.25mL, 0.2M) dropwise, and reacted at 200°C for 10min to prepare a transition layer with a thickness of 1.5nm; then add oil After reacting with cadmium acid for 1.5h, add S powder / ODE, react at 200°C for 15min, cool, and purify.

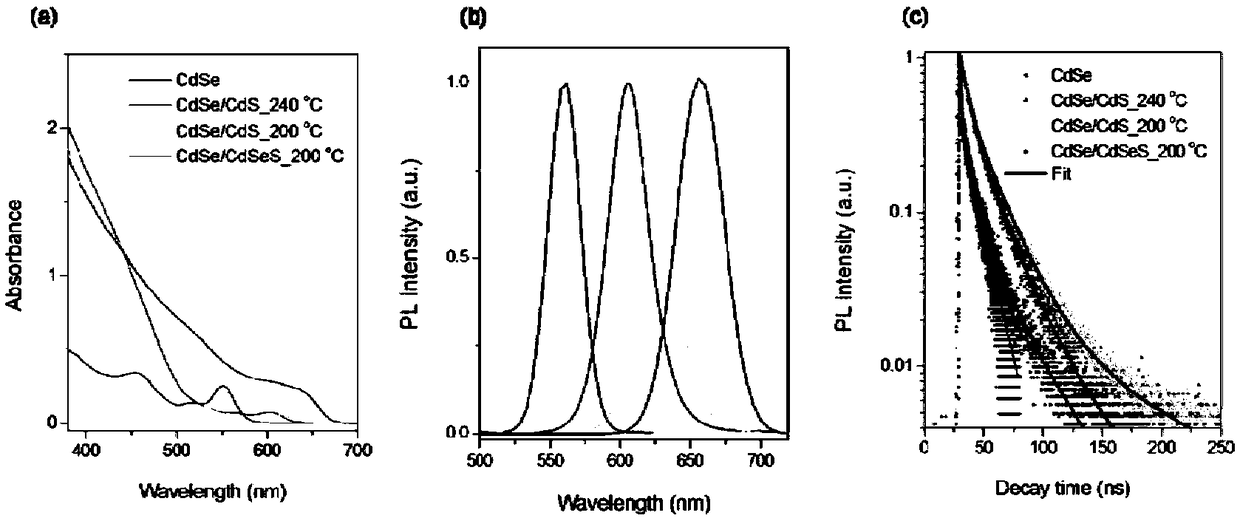

[0126] The absorption wavelength of the quantum dot is 300-700nm, the emission wavelength is 550-750nm, the half-peak width is 15nm, and the quantum yield is 50-90%.

Embodiment 2

[0128] A core-shell quantum dot with a transition layer, the quantum dot has a structure of CdSeTe / CdSe / CdS;

[0129] The difference between the preparation method and Example 1 is:

[0130] First, the quantum dot core CdSeTe was prepared by co-precipitation method;

[0131] Mix cadmium oleate, selenium powder, and tellurium powder at a molar ratio of 1:0.9:0.1, then heat to 200°C and react for 30 minutes.

[0132] The absorption wavelength of the quantum dot is 300-800nm, the emission wavelength is 600-900nm, the half-peak width is 30nm, and the quantum yield is 20-80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com