High temperature and humidity self control energy saving device for setting machine and processing method thereof

A technology of energy-saving device and setting machine, which is applied in control/adjustment system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problems of unsatisfactory exhaust gas treatment effect, more waste of production cost, and less exhaust gas recycling and utilization. , to avoid over-drying or insufficient drying, stabilize the humidity in the drying room, and save fuel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0032] Example.

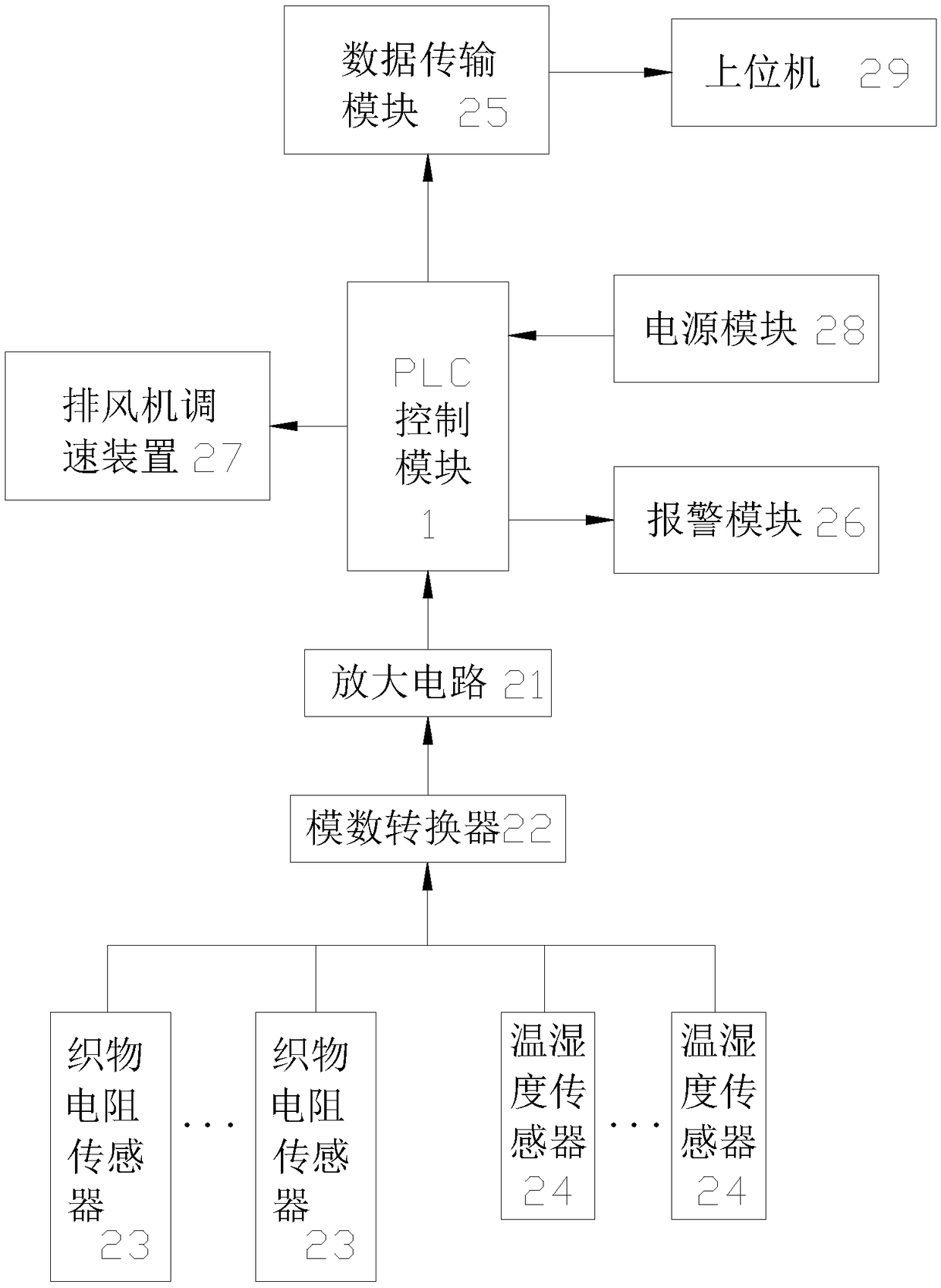

[0033] like figure 1 As shown, a high-temperature and humidity self-control energy-saving device for a sizing machine includes a PLC control module 1, and the PLC control module 1 is connected to a fabric resistance sensor 23 and a temperature and humidity sensor 24 respectively via an amplifier circuit 21 and an analog-to-digital converter 22 in turn, The PLC control module 1 is also connected with a data transmission module 25 , an alarm module 26 , an exhaust fan speed regulating device 27 and a power supply module 28 respectively. Both the fabric resistance sensor 23 and the temperature and humidity sensor 24 are provided with at least two. The temperature and humidity sensor 24 adopts a temperature and humidity sensor 24 whose model is DHT20.

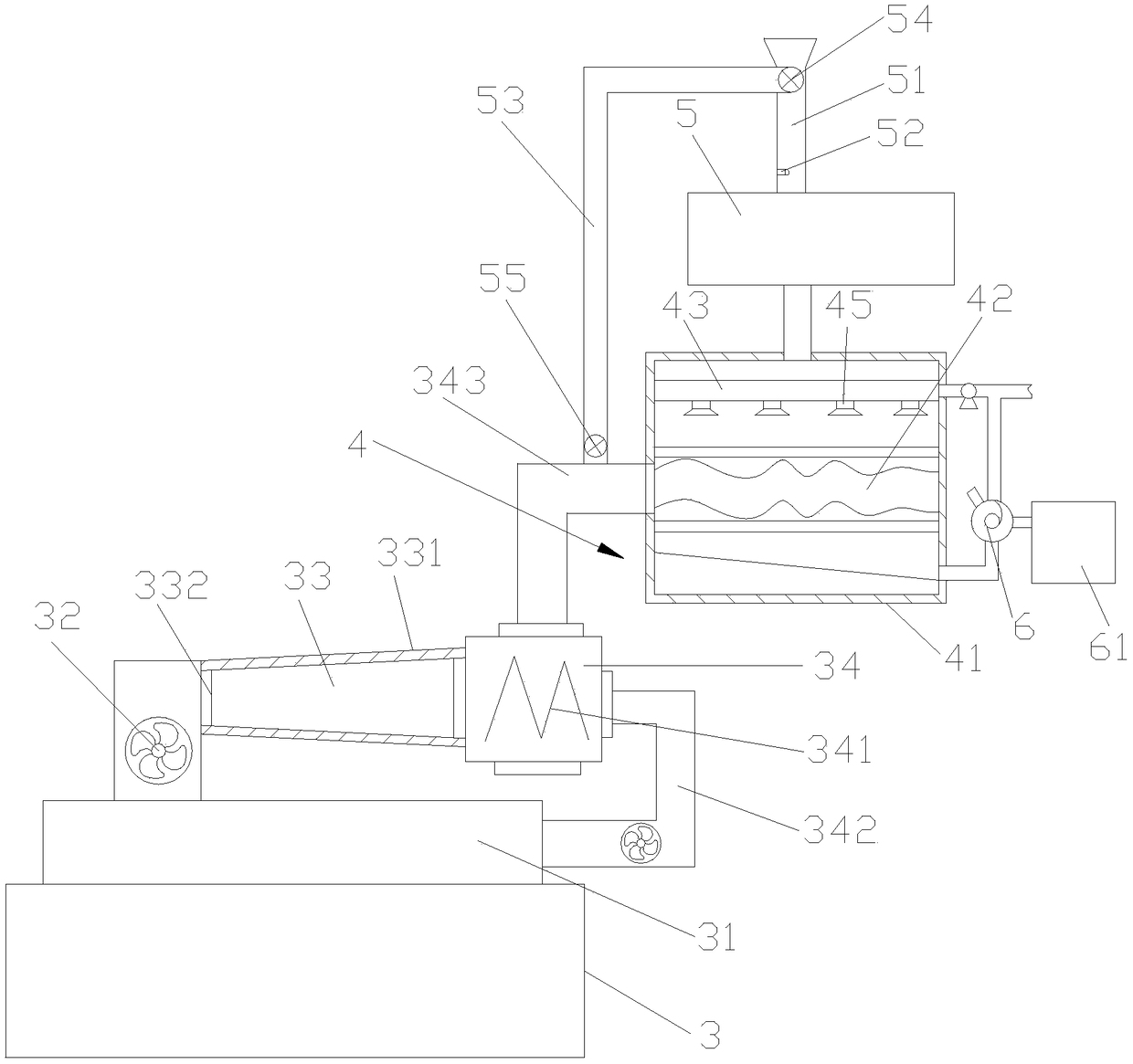

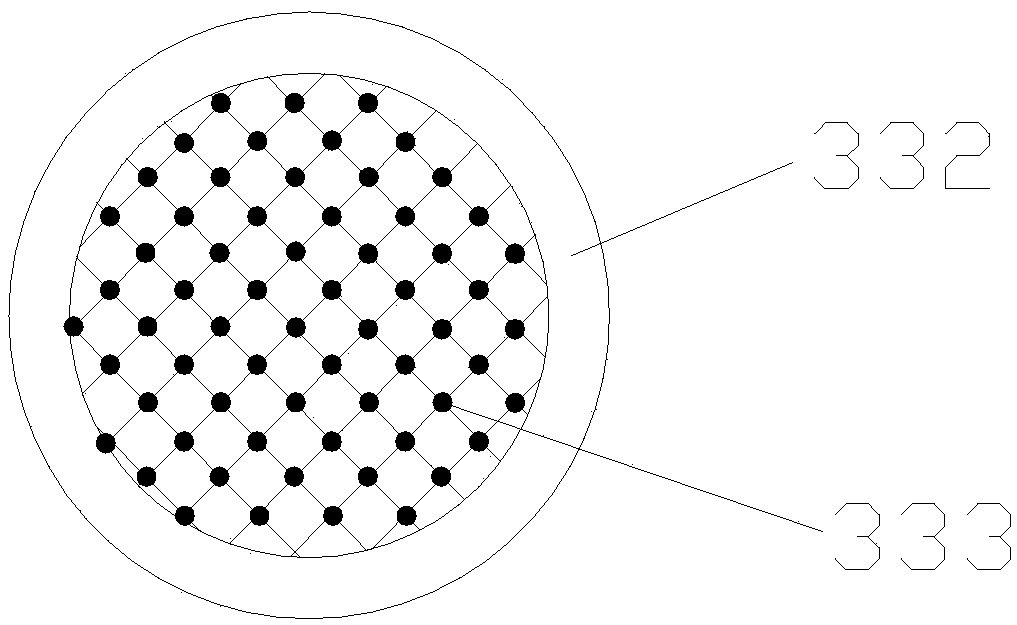

[0034] like figure 2 and image 3As shown, the exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com