Hazardous waste incineration process

A waste and process technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of disordered incineration conditions in the kiln, affecting the quality of flue gas burnout, leachate contamination of groundwater and soil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The hazardous waste incineration system and process of the present invention will be described in detail below in conjunction with the accompanying drawings. Those skilled in the art should understand that the embodiments described below are only illustrative illustrations of the present invention, and are not intended to limit it in any way.

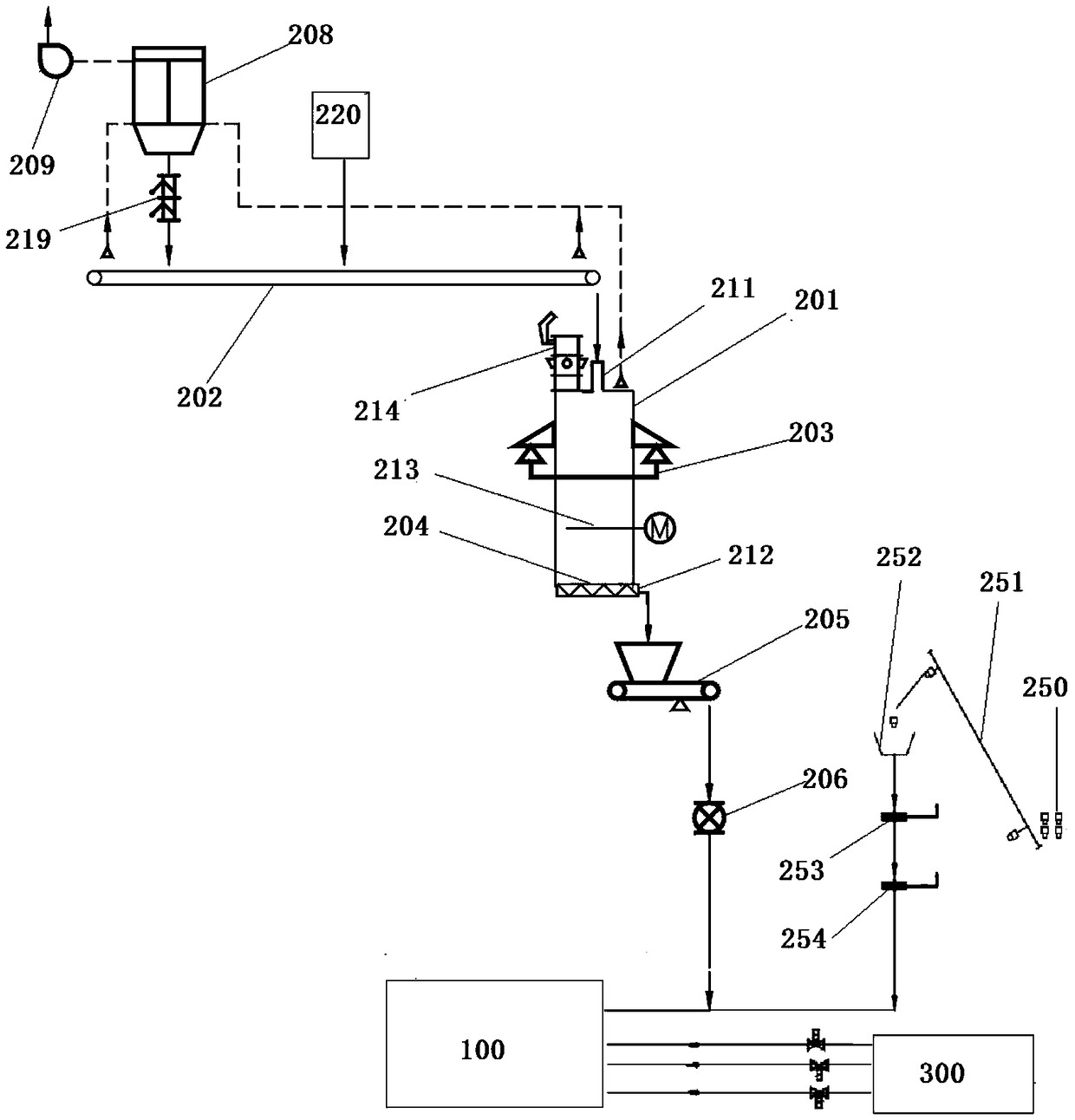

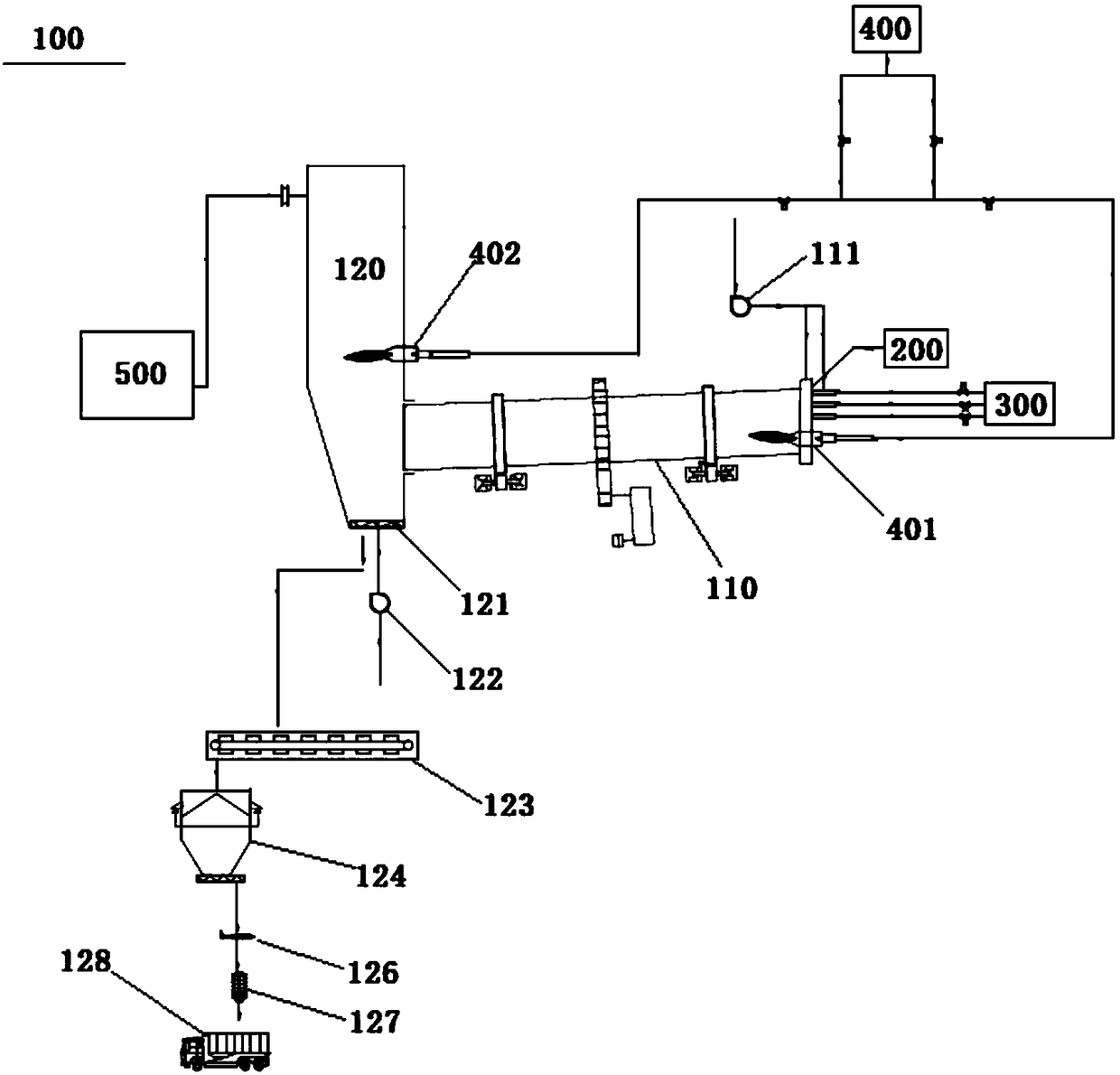

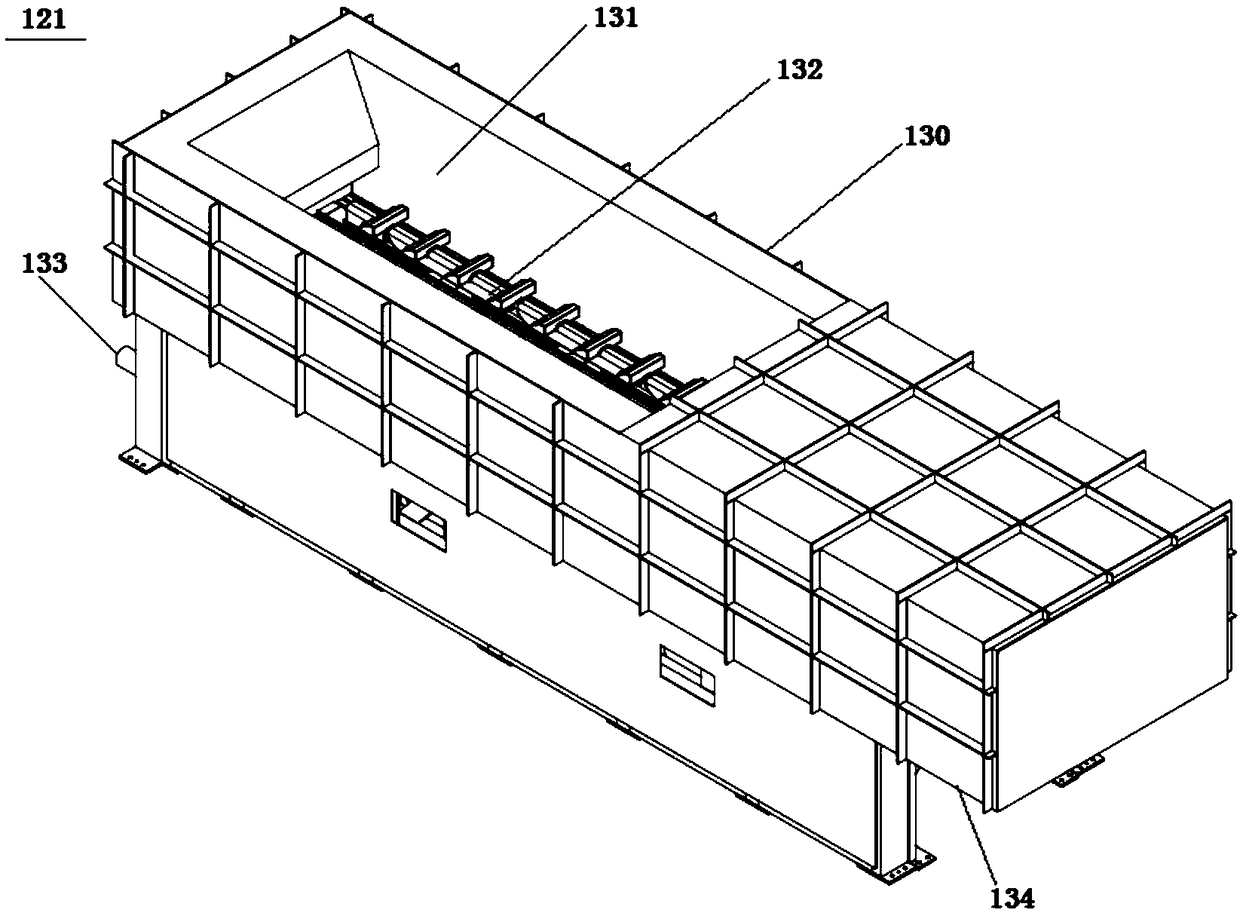

[0039] see Figure 1-Figure 6 , the hazardous waste incineration system according to the present invention mainly includes a feed system, an incineration device 100 and a tail gas treatment system 500 . The structure and working process of each system and device will be introduced in detail below.

[0040] In order to facilitate the compatibility and safe transportation of various materials, in the present invention, the hazardous waste to be treated is divided into three categories in advance: bulk material, bagged material and liquid material. The calorific value and chemical properties of the same type of material are similar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com