Small ultrafine grinder with self-cleaning mechanism

An ultra-fine pulverizer and self-cleaning technology, which is applied in grain processing and other directions, can solve the problems of low preparation efficiency of Chinese medicinal materials and difficulty in direct preparation of drug formulations, so as to reduce cleaning dead corners, reduce loss of Chinese medicinal materials, and reduce residues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

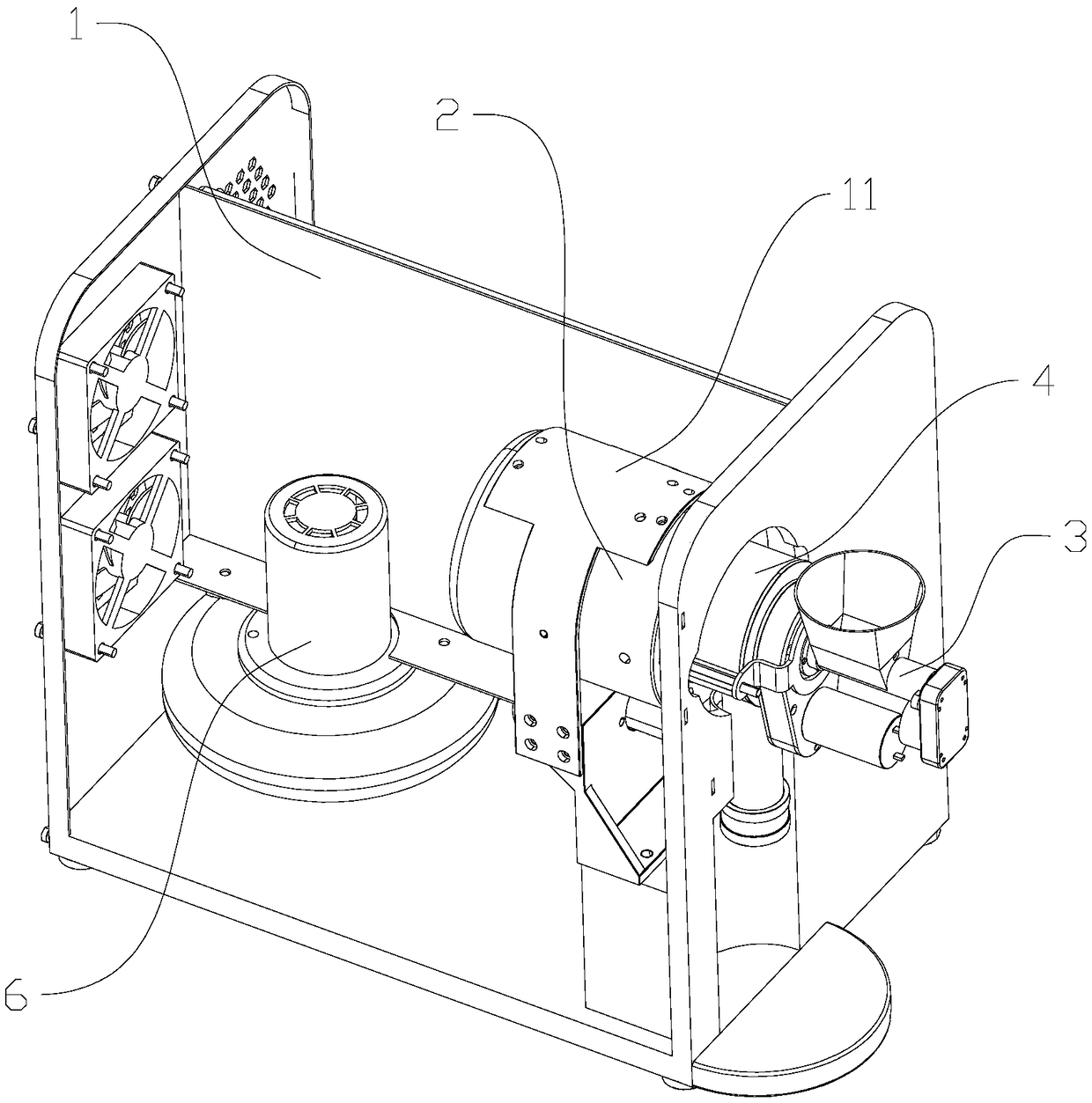

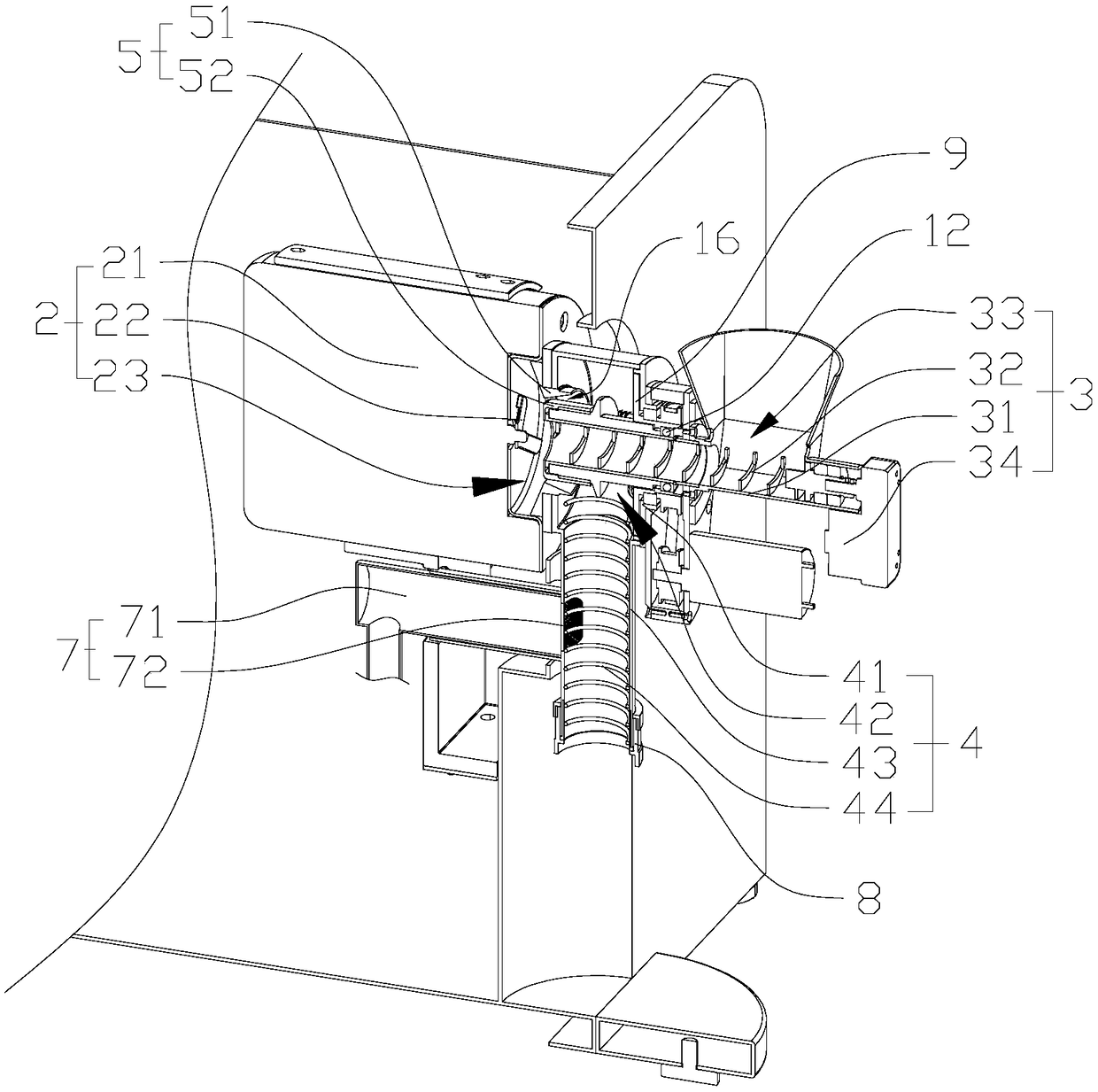

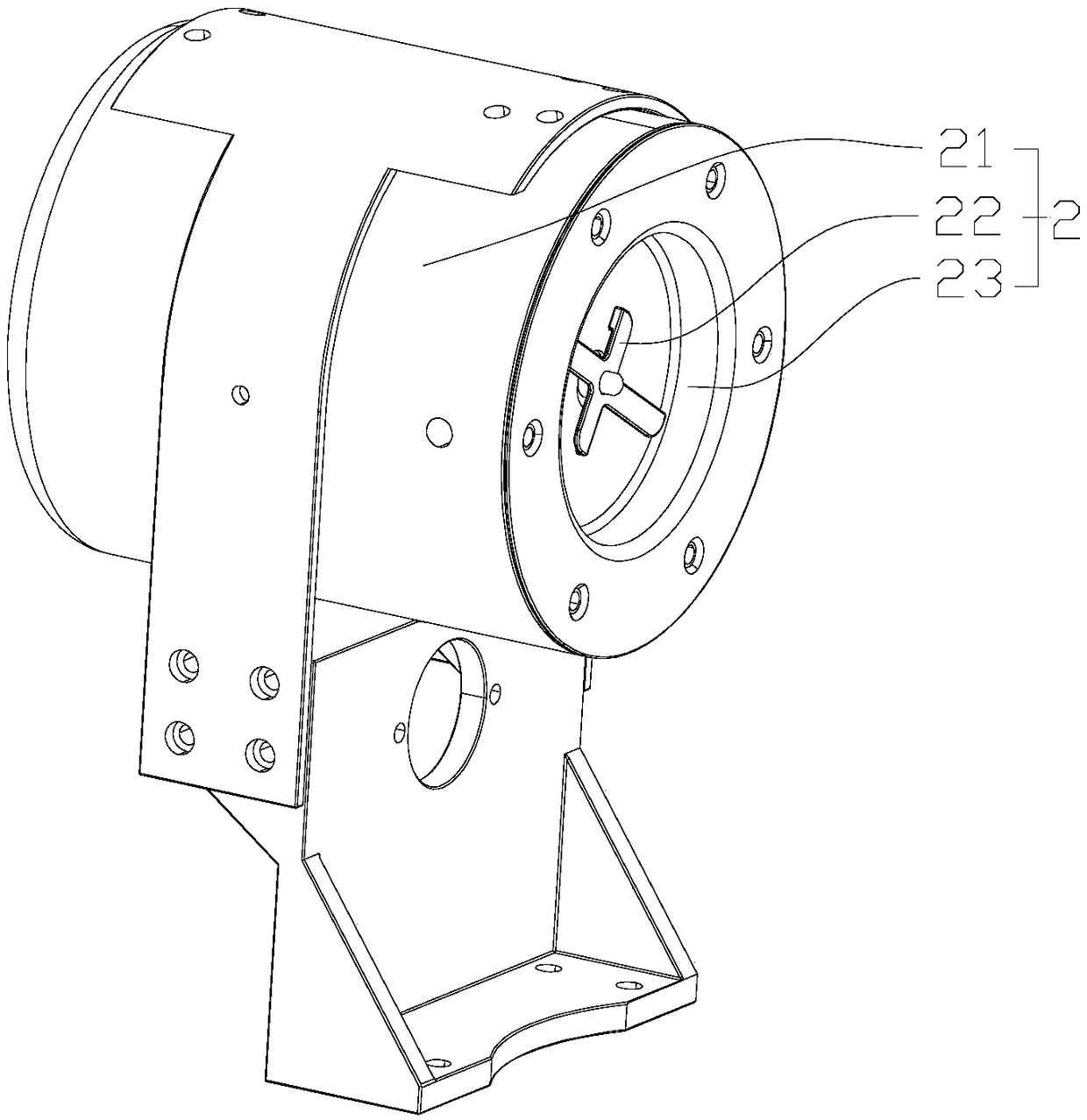

[0037] Such as figure 1 Shown, a kind of small ultrafine pulverizer of continuous pulverizing and discharging, comprises organic body 1, is arranged on body 1 pulverizing device 2, feeding device 3 and discharging device 4; figure 2 with image 3 As shown, the crushing device 2 includes a crushing chamber 23, a crushing blade 22 arranged in the crushing chamber 23, and a crushing motor 21 for the rotation of the crushing blade 22. The crushing motor 21 is fixedly arranged on the body 1 by a fixed bracket 11, and the crushing chamber 23 is connected with the feeding device 3 that is used for Chinese medicinal material to enter and the discharge device 4 that collects Chinese medicinal material powder; figure 2 with Figure 4 As shown, the feeding device 3 includes a feeding channel 31 communicated with the crushing chamber 23 and an auger 32 arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com