Method for detecting smoke composition of cigarette noncombustible under heating

A heat-not-burn, cigarette smoke technology, applied in measurement devices, material separation, analysis of materials, etc., can solve the problems of time-consuming, labor-intensive, and high detection costs, and achieve simple capture and extraction operations, good repeatability, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

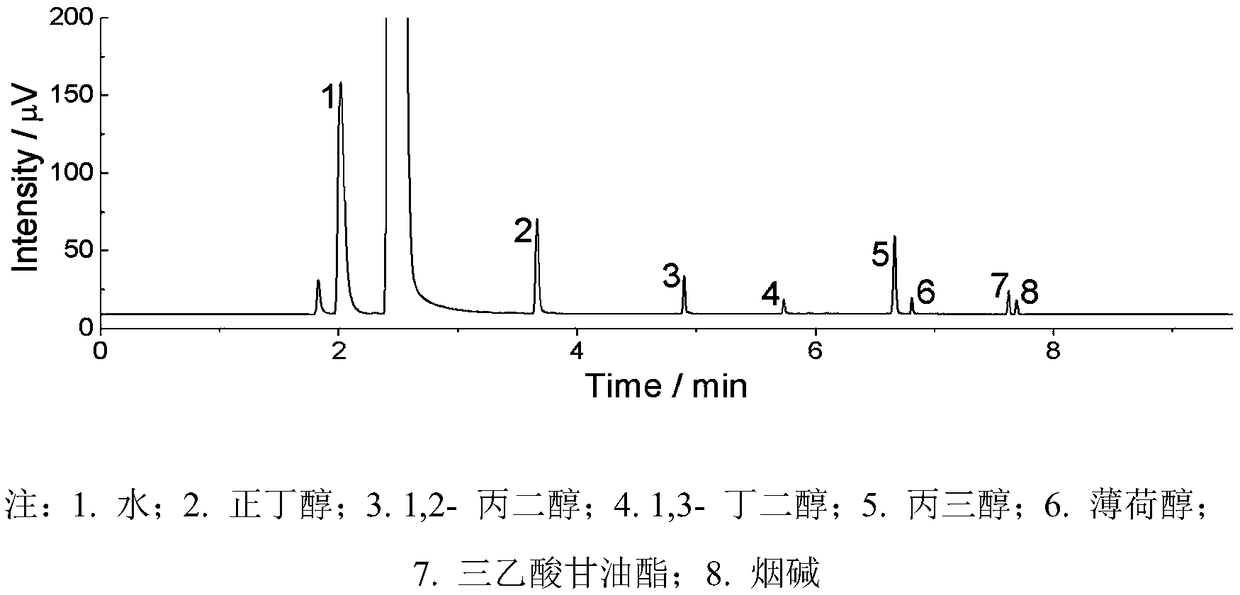

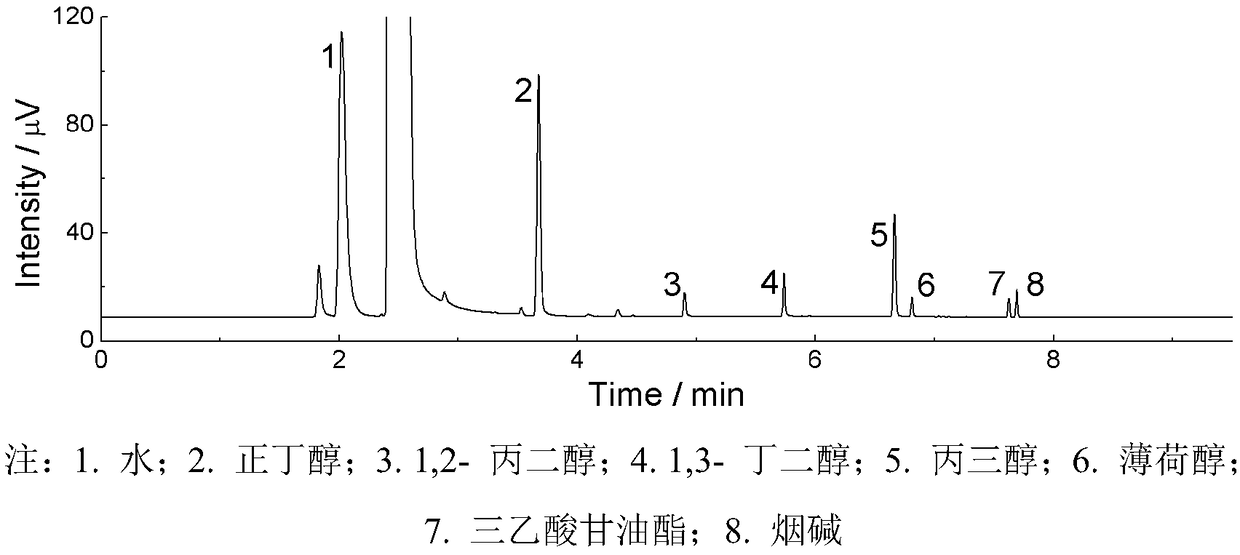

Image

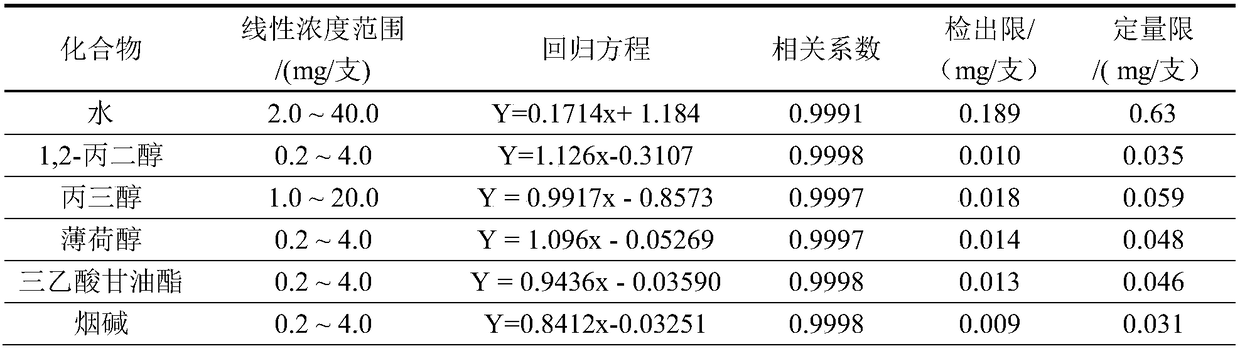

Examples

Embodiment 1

[0033] (1) Preparation of internal standard solution: Accurately weigh 2.000 g of internal standard samples n-butanol (purity ≥ 99%) and 0.2000 g of 1,3-butanediol (purity ≥ 99%), use chromatographically pure isopropanol as The solvent was fixed in a 1000mL volumetric flask to obtain an internal standard solution; the concentration of the internal standard n-butanol in the internal standard solution was 2 mg / mL, and the concentration of 1,3-butanediol was 0.2 mg / mL.

[0034] (2) Preparation of standard working solution: Accurately weigh 6.000g of pure water, 3.000g of glycerin standard (purity ≥ 99%), 0.6000g of nicotine standard (purity ≥ 99%), 1,2-propanediol standard product (purity ≥ 99%) 0.6000g, glycerol triacetate standard (purity ≥ 99.5%) 0.6000g, menthol standard (purity ≥ 99%) 0.6000g, with chromatographically pure isopropanol as a solvent to constant volume in 100mL In the volumetric flask, the standard stock solution was obtained, wherein the concentration of water...

Embodiment 2

[0049] As described in Example 1, the heat-not-burn cigarette sample B was tested, and all the steps were the same as in Example 1. The contents of each target substance in the smoke aerosol of sample B are shown in Table 2 for the results.

Embodiment 3

[0051] As described in Example 1, the heat-not-burn cigarette sample C was tested, and all the steps were the same as in Example 1. The contents of each target substance in the smoke aerosol of sample C are shown in Table 2 for the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com