Aldehyde-free color fixing agent for acid dyeing and preparation method thereof

A technology of formaldehyde-free color-fixing agent and acid dye, which is applied in the field of textile printing and dyeing, can solve the problems of unsatisfactory color fastness, low color fastness effect, small molecular weight, etc., to improve dry rubbing fastness, increase dry Wet fastness, little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

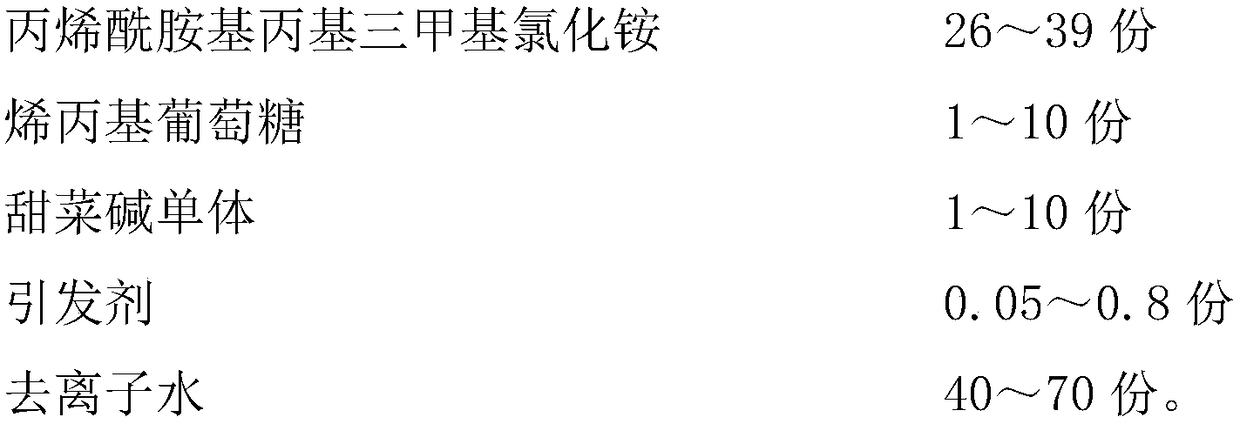

[0032] A kind of formaldehyde-free color-fixing agent for acid dye dyeing of the present invention is made of the following raw material components in proportion by mass:

[0033]

[0034] A kind of preparation method of the aldehyde-free color-fixing agent that is used for acid dye dyeing of the present invention, realizes by following steps:

[0035] (1) Add 26.5 parts of acrylamidopropyltrimethylammonium chloride, 1.3 parts of allyl glucose, 1.5 parts of N-acryloyloxymethyl-N, N-dimethylammonium-α- N-methylcarboxybetaine, 60.7 parts of deionized water, start stirring, and start to heat up;

[0036] (2) When the temperature in the reactor rose to 91°C, start to drop the initiator solution whose mass concentration was 8.7%. This initiator solution was prepared from 0.87 parts of ammonium persulfate and 9.13 parts of deionized water. The time is controlled at 3.3 hours. While adding the initiator dropwise, turn on the ultraviolet light to irradiate the reaction solution. T...

Embodiment 2

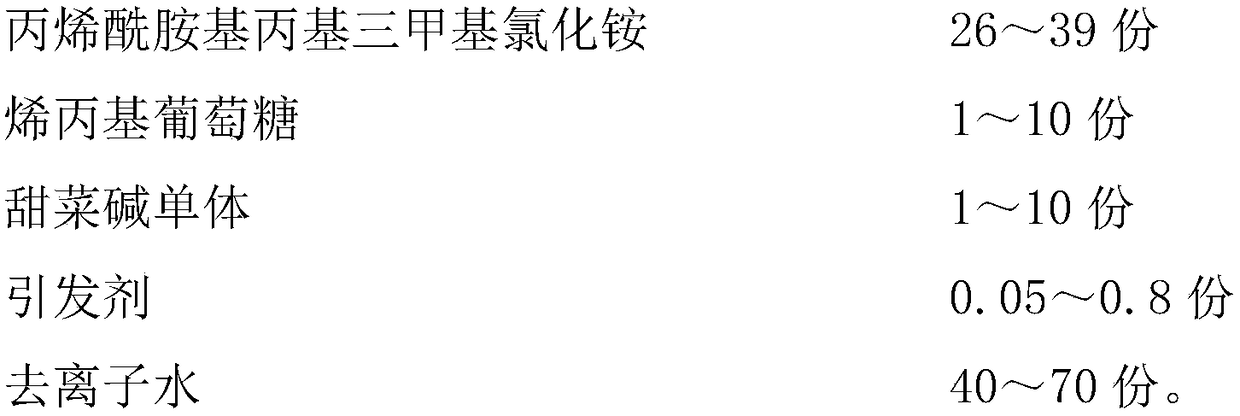

[0039] A kind of formaldehyde-free color-fixing agent for acid dye dyeing of the present invention is made of the following raw material components in proportion by mass:

[0040]

[0041]

[0042] A kind of preparation method of the aldehyde-free color-fixing agent that is used for acid dye dyeing of the present invention, realizes by following steps:

[0043] (1) Add 29 parts of acrylamidopropyltrimethylammonium chloride, 2.2 parts of allyl glucose, 2.9 parts of N-acryloyloxyethyl-N, N-dimethylammonium-α- N-methylcarboxybetaine, 55.9 parts of deionized water, start stirring, and start to heat up;

[0044] (2) When the temperature in the reactor rose to 92°C, start to drop the initiator solution whose mass concentration was 1.8%. This initiator solution was prepared from 0.18 parts of ammonium persulfate and 9.82 parts of deionized water. The time is controlled at 4.7 hours. While adding the initiator dropwise, turn on the ultraviolet light to irradiate the reaction so...

Embodiment 3

[0047] A kind of formaldehyde-free color-fixing agent for acid dye dyeing of the present invention is made of the following raw material components in proportion by mass:

[0048]

[0049] A kind of preparation method of the aldehyde-free color-fixing agent that is used for acid dye dyeing of the present invention, realizes by following steps:

[0050] (1) Add 31 parts of acrylamidopropyltrimethylammonium chloride, 4.3 parts of allyl glucose, 3.8 parts of N-acryloxypropyl-N, N-dimethylammonium-α- N-methylcarboxybetaine, 50.9 parts of deionized water, start stirring, and start to heat up;

[0051] (2) When the temperature in the reactor rose to 113°C, start to drop the initiator solution whose mass concentration was 2.3%. This initiator solution was prepared from 0.23 parts of sodium persulfate and 9.77 parts of deionized water. The time is controlled at 3.6 hours. While adding the initiator dropwise, turn on the ultraviolet light to irradiate the reaction solution. The ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com