High-strength aramid paper sandwich composite structure and manufacturing method thereof

A technology of composite structure and manufacturing method, which is applied in the field of aramid fiber manufacturing, can solve problems such as damage and damage, and achieve the effects of improving external bearing capacity, large volume resistance, and reducing load bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

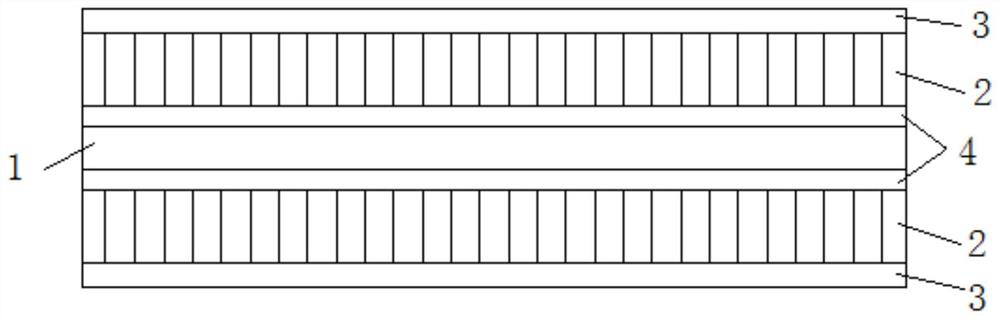

[0027] refer to figure 1 As shown, this embodiment is a high-strength aramid paper sandwich composite structure, including a polyester film 1, an aramid paper honeycomb core 2 disposed on both sides of the polyester film 1, and a resin resin disposed on the outside of the aramid paper honeycomb core 2. The fiber layer 3, the polyester film 1 and the aramid paper honeycomb core 2 are bonded by an adhesive 4;

[0028] The space section of the aramid paper honeycomb core 2 is a square, and the paper thickness of the aramid paper honeycomb core 2 is 0.05mm;

[0029] The resin fiber layer 3 is a fiber cloth impregnation layer formed by impregnating the fiber cloth with the resin composition, and the resin composition includes 3 parts of phenolic propane epoxy resin, 20 parts of tetraphenol based epoxy resin, 5 parts of polyethersulfone, 5 parts of emulsifier, 3 parts of acetone, 6 parts of ethylene glycol monomethyl ether;

[0030] The raw material of adhesive 4 comprises the fol...

Embodiment 2

[0045] refer to figure 1 As shown, this embodiment is a high-strength aramid paper sandwich composite structure, including a polyester film 1, an aramid paper honeycomb core 2 disposed on both sides of the polyester film 1, and a resin resin disposed on the outside of the aramid paper honeycomb core 2. The fiber layer 3, the polyester film 1 and the aramid paper honeycomb core 2 are bonded by an adhesive 4;

[0046] The space section of the aramid paper honeycomb core 2 is a square, and the paper thickness of the aramid paper honeycomb core 2 is 0.07mm;

[0047] The resin fiber layer 3 is a fiber cloth impregnation layer formed by impregnating the fiber cloth with the resin composition, and the resin composition includes 8 parts of phenolic propane epoxy resin, 10 parts of tetraphenol based epoxy resin, 15 parts of polyethersulfone, 1 part of emulsifier, 8 parts of acetone, 3 parts of ethylene glycol monomethyl ether;

[0048] The raw material of adhesive 4 comprises the fol...

Embodiment 3

[0063] refer to figure 1 As shown, this embodiment is a high-strength aramid paper sandwich composite structure, including a polyester film 1, an aramid paper honeycomb core 2 disposed on both sides of the polyester film 1, and a resin resin disposed on the outside of the aramid paper honeycomb core 2. The fiber layer 3, the polyester film 1 and the aramid paper honeycomb core 2 are bonded by an adhesive 4;

[0064] The space section of the aramid paper honeycomb core 2 is a square, and the paper thickness of the aramid paper honeycomb core 2 is 0.06mm;

[0065] The resin fiber layer 3 is a fiber cloth impregnation layer formed by impregnating the fiber cloth with a resin composition. The resin composition includes 5 parts of phenolic propane epoxy resin, 15 parts of tetraphenol based epoxy resin, 10 parts of polyethersulfone, 3 parts of emulsifier, 5 parts of acetone, 4 parts of ethylene glycol monomethyl ether;

[0066] The raw material of adhesive 4 comprises the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com