Dispersible solid preparation for preventing fruit drop and its preparation method and use

A technology of dispersant and fruit, which is applied in the field of dispersible solid preparations and its preparation, can solve the problems of 1-methylcyclopropene effect reduction, unrecorded preparation, uneven drug distribution, etc., achieve good thermal storage stability, prevent The effect of mutual aggregation and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

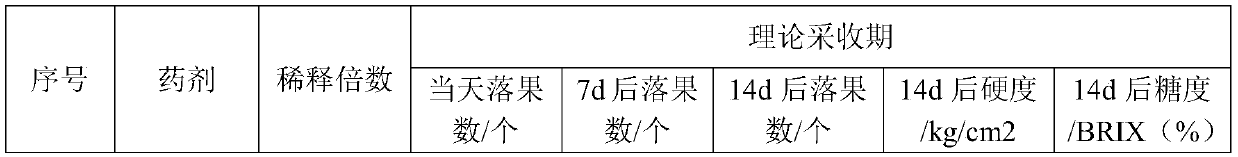

Image

Examples

Embodiment 1

[0041] Embodiment 1: 0.033% 1-methylcyclopropene microcapsule wettable powder

[0042] The selection and ratio of original drug and additives are: 1-methylcyclopropene microcapsule granule 1%, dispersant polycarboxylate 5%, wetting agent saponin powder 3%, stabilizer 2,6-ditert-tert Butyl-4-methylphenol 1%, solid carrier calcined kaolin 90%.

[0043] Preparation methods include:

[0044] 1) Pulverization: 1% of 1-methylcyclopropene microcapsules, 5% of dispersant polycarboxylate, 3% of wetting agent saponin powder, 1% of stabilizer 2,6-ditertiary Butyl-4-methylphenol is mixed with 90% solid carrier calcined kaolin, mechanically pulverized, airflow pulverized, and then mixed;

[0045] 2) Detection: After the determination of the control indicators, the water in the final product is 2.33%, the pH value is 6.37, the mass suspension rate is 98.12%, the wetting time is 43.0s, and the fineness (wet sieve, passing through a 45μm test sieve) is 99.2 %, the content of 1-methylcyclop...

Embodiment 2

[0046] Embodiment 2: 0.825% 1-methylcyclopropene microcapsule wettable powder

[0047] The selection and ratio of the original drug and additives are: 1-methylcyclopropene microcapsule granule 25%, dispersant naphthalenesulfonate formaldehyde condensate 5%, wetting agent sodium lauryl sulfate 3%, stabilizer Tert-butyl p-hydroxyanisole 1%, solid carrier kaolin 66%.

[0048] Preparation methods include:

[0049] 1) Pulverization: 25% of 1-methylcyclopropene microcapsules, 5% of dispersant naphthalenesulfonate formaldehyde condensate, 3% of wetting agent sodium lauryl sulfate, 1% of stabilizer tert-butyl-p-hydroxyanisole is mixed with 66% solid carrier kaolin, mechanically pulverized, then air-jet pulverized, and then mixed;

[0050] 2) Detection: After the determination of the control indicators, the water in the final product is 3.13%, the pH value is 6.78, the mass suspension rate is 97.23%, the wetting time is 35.0s, and the fineness (wet sieve, passing through a 45μm test ...

Embodiment 3

[0051] Embodiment 3: 1.650% 1-methylcyclopropene microcapsule wettable powder

[0052] The selection and ratio of the original drug and additives are: 1-methylcyclopropene microcapsules 50%, dispersant sodium lignosulfonate 5%, wetting agent pull-off powder 3%, stabilizer propyl gallate 1 %, solid carrier bentonite 41%.

[0053] Preparation methods include:

[0054] 1) Pulverization: 50% 1-methylcyclopropene microcapsules, 5% dispersant sodium lignosulfonate, 3% wetting agent pull apart powder, 1% stabilizer propyl gallate and 41% of the solid carrier bentonite is mixed, mechanically pulverized, then jet pulverized, and then mixed;

[0055] 2) Detection: After the determination of the control indicators, the water in the final product is 2.69%, the pH value is 7.43, the mass suspension rate is 98.56%, the wetting time is 22.0s, and the fineness (wet sieve, passing through a 45μm test sieve) is 99.6 %, 1-methylcyclopropene content is 1.648%, the product is qualified, and 1.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com