Device for positioning tunnel secondary lining steel bar layer spacing and protection layer

A positioning device and reinforcement layer technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of high cost and large amount of L reinforcement positioning, and achieve the effect of preventing exposed reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the invention:

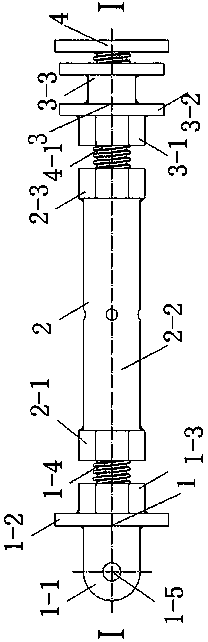

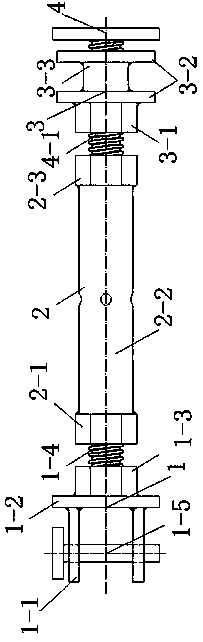

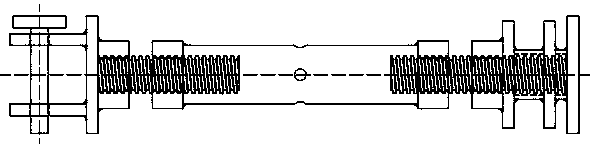

[0018] The positioning device is composed of a fixed pipe body 2, a U-shaped chuck 1 and a chuck 3. The U-shaped chuck 1 is formed by welding two ear plates 1-1 with holes on the steel plate 1-2, and the two ear plates 1-1 with holes are equipped with pins 1-5; the right side of the steel plate 1-2 is welded with a screw rod 1 -4 and nut 1-3; fixed pipe body 2 is formed by welding nut 2-1 and nut 2-3 at both ends of round pipe 2-2; chuck 3 is welded round at both ends of cylinder 3-3 Steel plate 3-2 forms, and chuck 3 left side welding nut 3-1.

[0019] The left end of the fixed pipe body 2 is connected to the U-shaped chuck 1 through the screw rod 1-4, and the right end is connected to the base 4 through the screw rod 4-1; the chuck 3 is set on the screw rod 4-1 through the nut 3-1.

[0020] The method of use is as follows:

[0021] Measure and set out, connect the long ring main steel bars to the pre-embedded steel bars on the short ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com