Thickness control device for cast-in-place concrete floor slabs and steel bar protective layers

A technology for steel protection layer and thickness control, which is applied in the processing of floor slabs, building materials, structural elements, etc., can solve the problem of lack of universality, etc., and achieve the effect of simple structure, improved work efficiency, and prevention of exposed reinforcement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

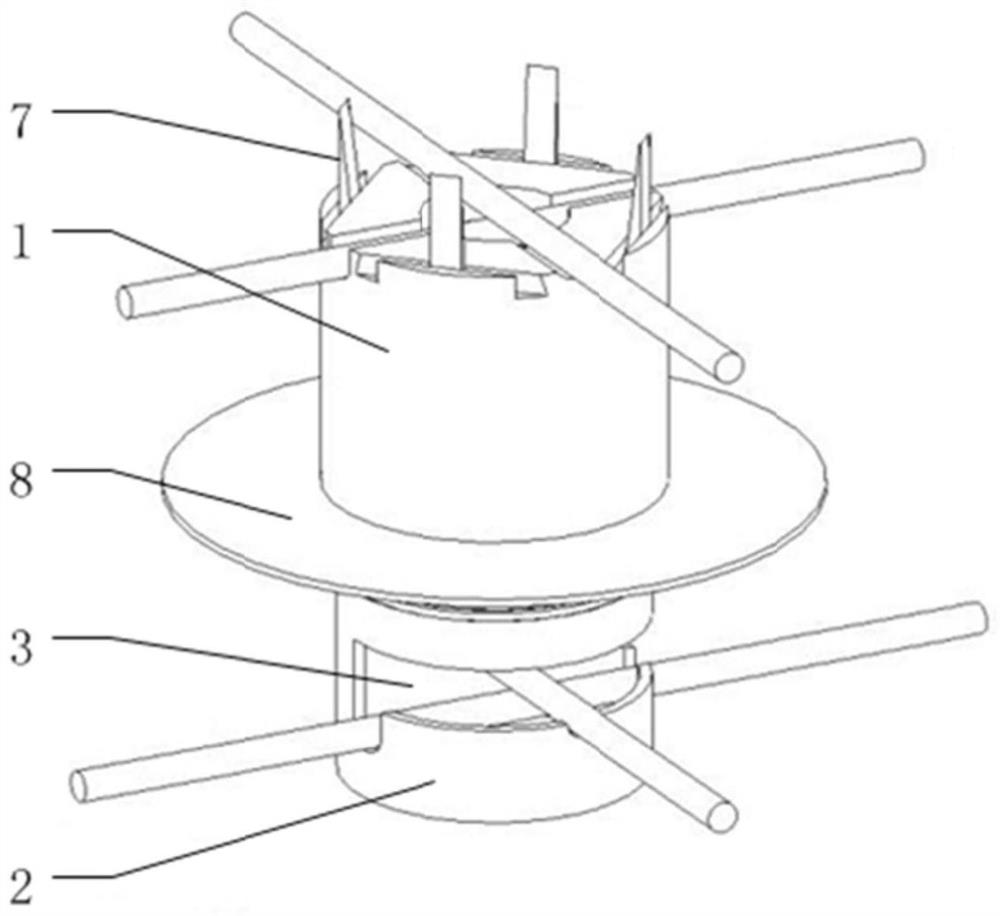

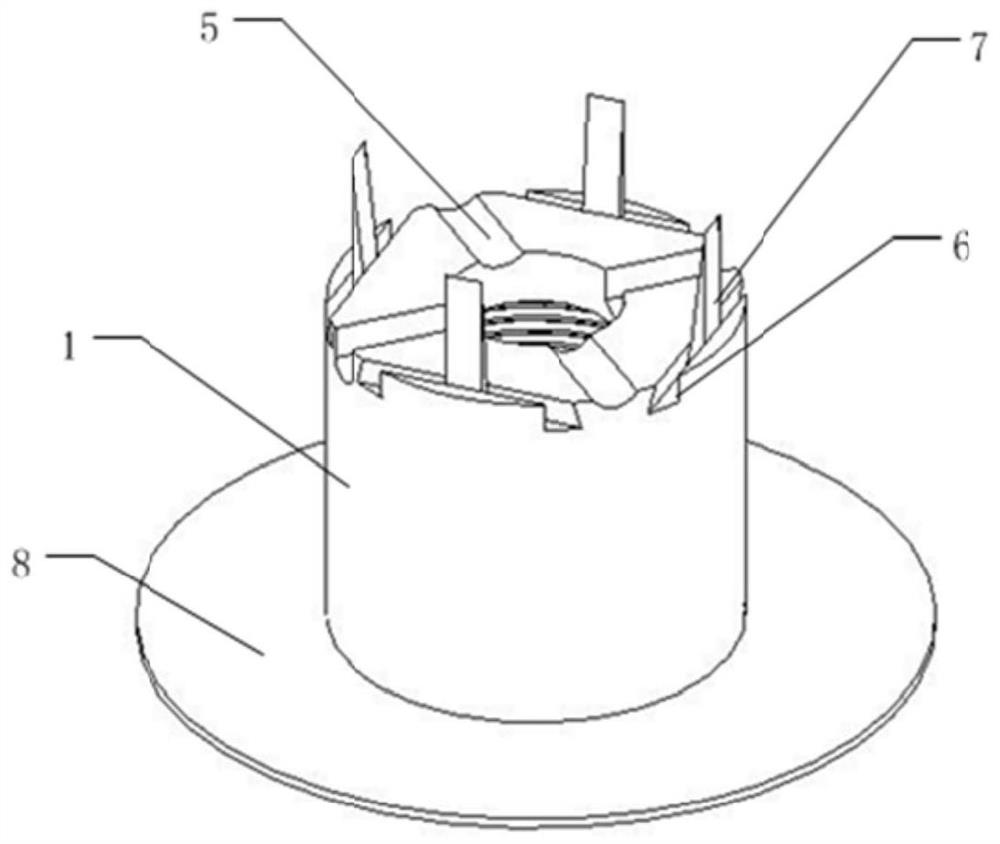

[0022] refer to figure 1 , is a thickness control device for cast-in-place concrete floor slabs and steel bar protection layers disclosed in the present invention, comprising an adjustable cylinder 1 and a fixed base 2, both of which are hollow columnar structures, wherein, The inner wall of the adjustable cylinder 1 is provided with internal threads, the outer wall of the fixed base 2 is provided with external threads, and the adjustable cylinder 1 is threadedly connected to the fixed base 2 through the mutual cooperation of the internal and external threads.

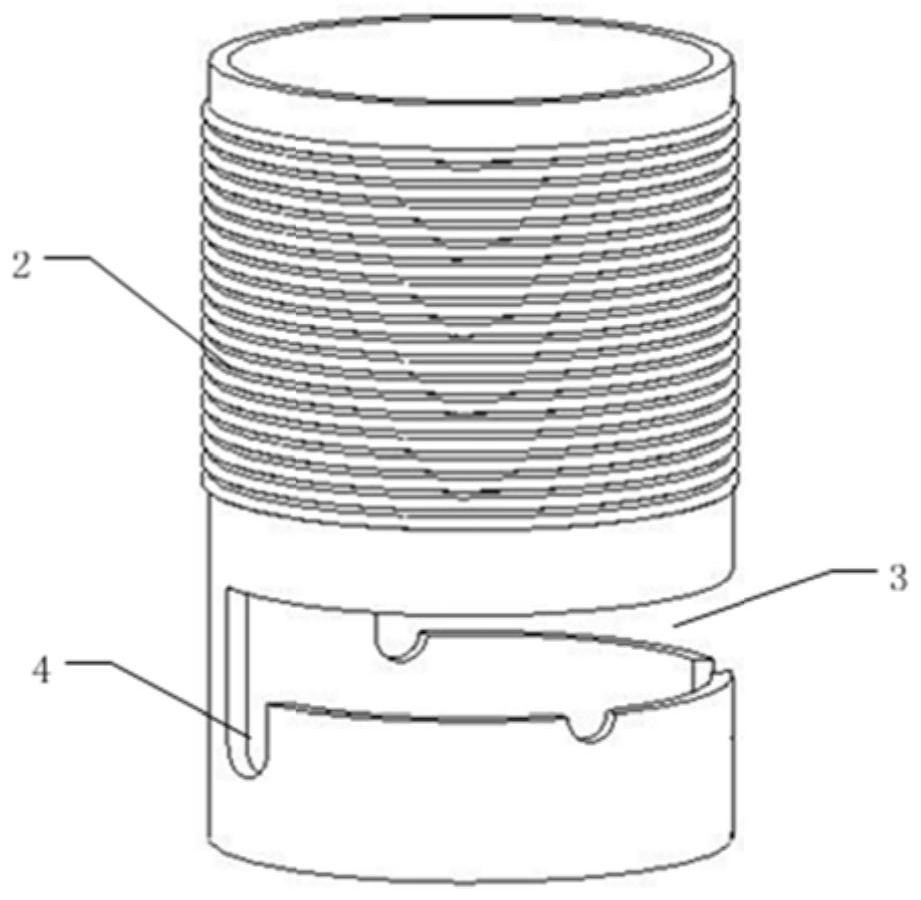

[0023] refer to figure 2 , the lower part of the fixed base 2 is horizontally provided with a gap 3, and the height of the gap 3 is not less than twice the height of the steel bar diameter. Thickness, relative rotation of the adjustable cylinder 1 and the fixed base 2, adjust the height of the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com