Movable tool type construction berm bracket

A technology for moving tools and bridleways, which is applied in the field of movable tool-type construction bridleways, which can solve problems affecting construction quality and efficiency, non-disassembly and adjustment, and increased labor intensity, so as to improve construction quality, avoid exposed ribs, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

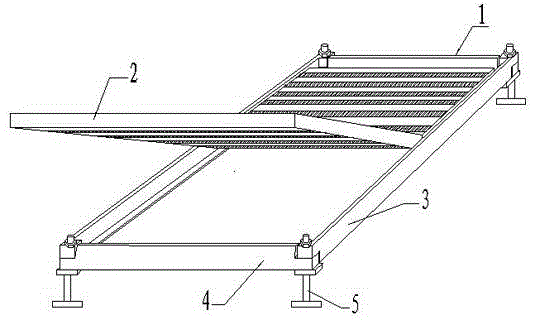

[0030] Embodiment 1 of the present invention provides a kind of movable tool type construction horse track support, as figure 1 , the construction path is composed of a square frame 1 and a walking plank 2, wherein the square frame 1 is formed by connecting two relatively parallel transverse connecting frames 3 and two relatively parallel longitudinal connecting frames 4 through end-to-end connection, wherein The connecting foot support 5 is connected and fixed;

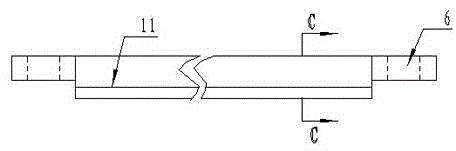

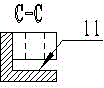

[0031] Such as figure 2 , the middle part of the frame body of the horizontal connecting frame 3 of the square frame 1 protrudes a lapping surface 11 laterally, such as image 3 , its cross-section is L-shaped, and two ends are respectively provided with an upper lap ear 6, wherein the height of the upper lap ear 6 is half of the height of the connecting frame 3, and the upper end surface of the upper lap ear 6 is equal to the upper end face of the connecting frame 3 , the middle part of the upper lap ear 6 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com