Micro-expansive concrete suitable for corrugated steel webs

A corrugated steel web and concrete composition technology, which is applied in the field of building materials, can solve the problems of poor uniformity, loss of integrity, and many cavities in the lining concrete, so as to avoid cracking and voiding, reduce self-weight, and increase construction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

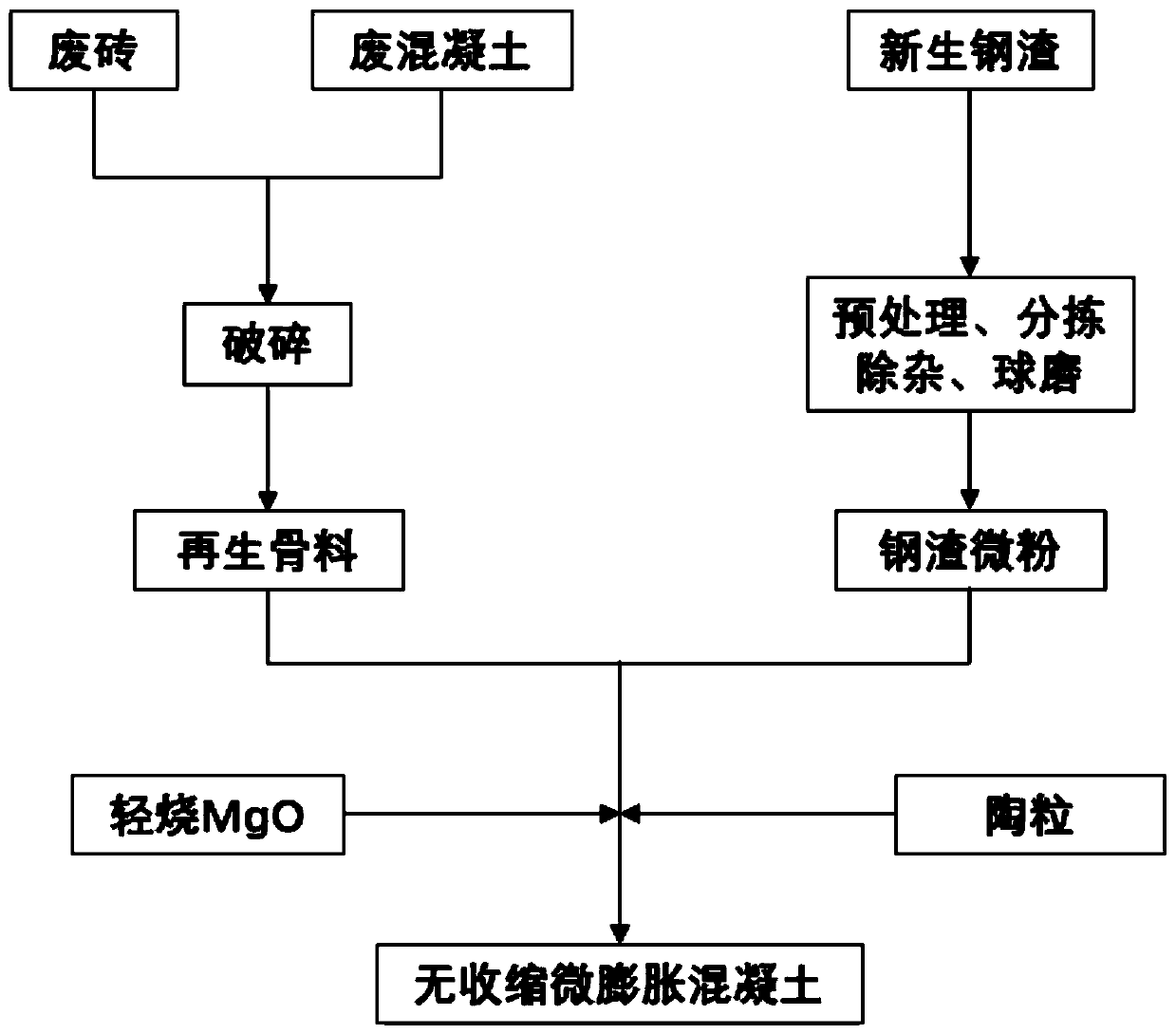

Method used

Image

Examples

Embodiment 1~7

[0111] (1) Prepare raw materials:

[0112] Cement: P O42.5 ordinary Portland cement, apparent density is 3.10g / cm 3 .

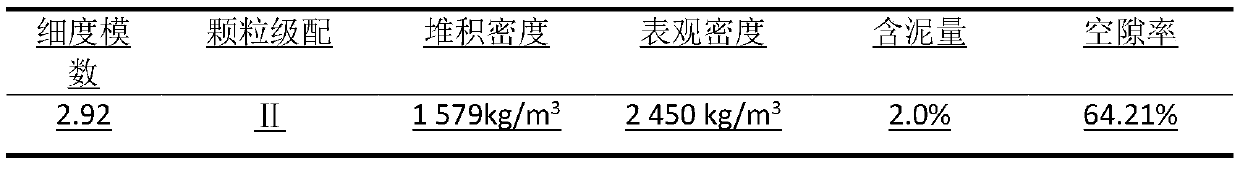

[0113] Fine aggregate: medium sand, <5mm, qualified for grading. The performance indicators of medium sand are shown in Table 1.

[0114] Sand performance index in Table 1

[0115]

[0116] Natural coarse aggregate: crushed stone with a continuous particle size of 5-20mm, and an apparent density of 2.75g / cm 3 , bulk density is 1.35g / cm 3 , The water absorption rate is 0.45%.

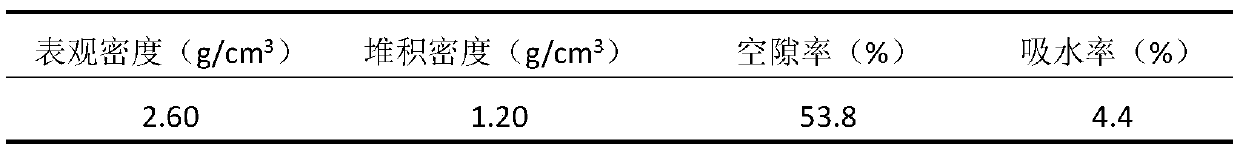

[0117] Recycled Coarse Aggregate: Sorting, crushing and screening the waste concrete in construction waste, such as waste concrete, waste mortar, waste bricks and tiles in construction (construction) waste, and screening out those less than 9.50mm and greater than 20mm After granulation, the recycled coarse aggregate is processed with the aggregate particle size in the range of 10mm to 20mm. Its performance is shown in Table 2.

[0118] Table 2 Performance indicators of recyc...

Embodiment 8-11

[0138] Embodiment 8-11 Concrete deformation performance testing experiment

[0139] The purpose of the experiment: To analyze the influence of different amounts of MgO and steel slag powder on the deformation properties of concrete

[0140] Test method: Concrete embedded strain gauge to measure its drying shrinkage. Specific method: After demoulding, the specimen is cured under dry conditions with a temperature of (20±1)°C and a relative humidity of (60±5)% (control the humidity with NaBr saturated salt solution). Used to measure the expansion rate L of concrete A The calculation formula: L A =[(L 1 -L0) / L]×100%, where L 0 is the initial length, L 1 L is the length of concrete at the corresponding age, and L is the effective length of the specimen, which is 250mm; the calculation formula for measuring the strain of concrete is as follows:

[0141] ε m =k(F-F 0 )+(b-α)(T-T 0 )

[0142] Where: ε m is the strain of the measured object, unit 10 -6 / F;

[0143] K is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com