Special heat-resistant, high-impact and flame-retardant resin for outer casing of storage battery

A flame retardant resin and storage battery technology, which is applied in the direction of battery box/cover, battery pack parts, battery box/cover material, etc., can solve the problems of impact deformation of battery shell, product expansion, hard rubber material, etc., and achieve high resistance Combustibility performance, improved corrosion resistance, and high impact resistance have remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

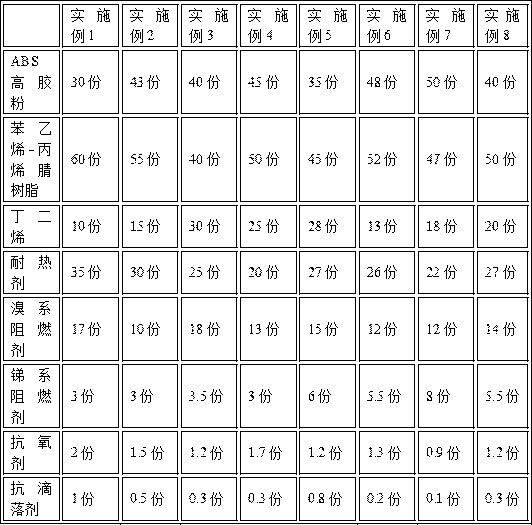

[0024] According to the data of the embodiment, a special heat-resistant, high-impact, and flame-retardant resin for battery casings, the components and parts by mass in its raw materials are: 30-50 parts of ABS high-grade rubber powder, 40-50 parts of styrene-acrylonitrile resin 60 parts, 10-30 parts of butadiene, 20-35 parts of heat-resistant agent, 10-18 parts of brominated flame retardant, 3-8 parts of antimony-based flame retardant, 0.5-2 parts of antioxidant, anti-dripping 0.1-1 part of the agent, each component within this ratio range can produce a suitable battery case, which has heat resistance, corrosion resistance, high impact resistance and significant fire resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com