Activated carbon for supercapacitor and preparation method and application of activated carbon

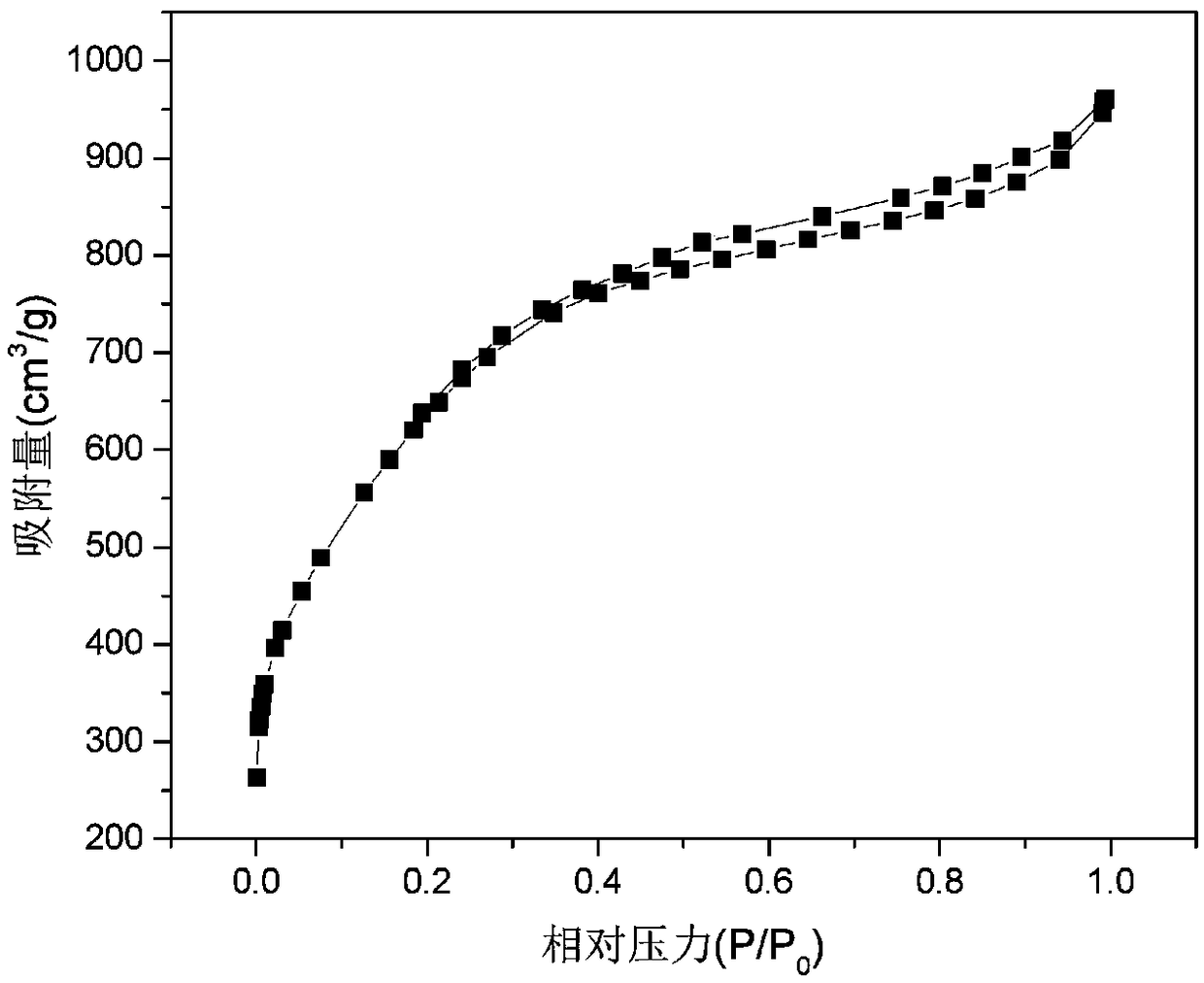

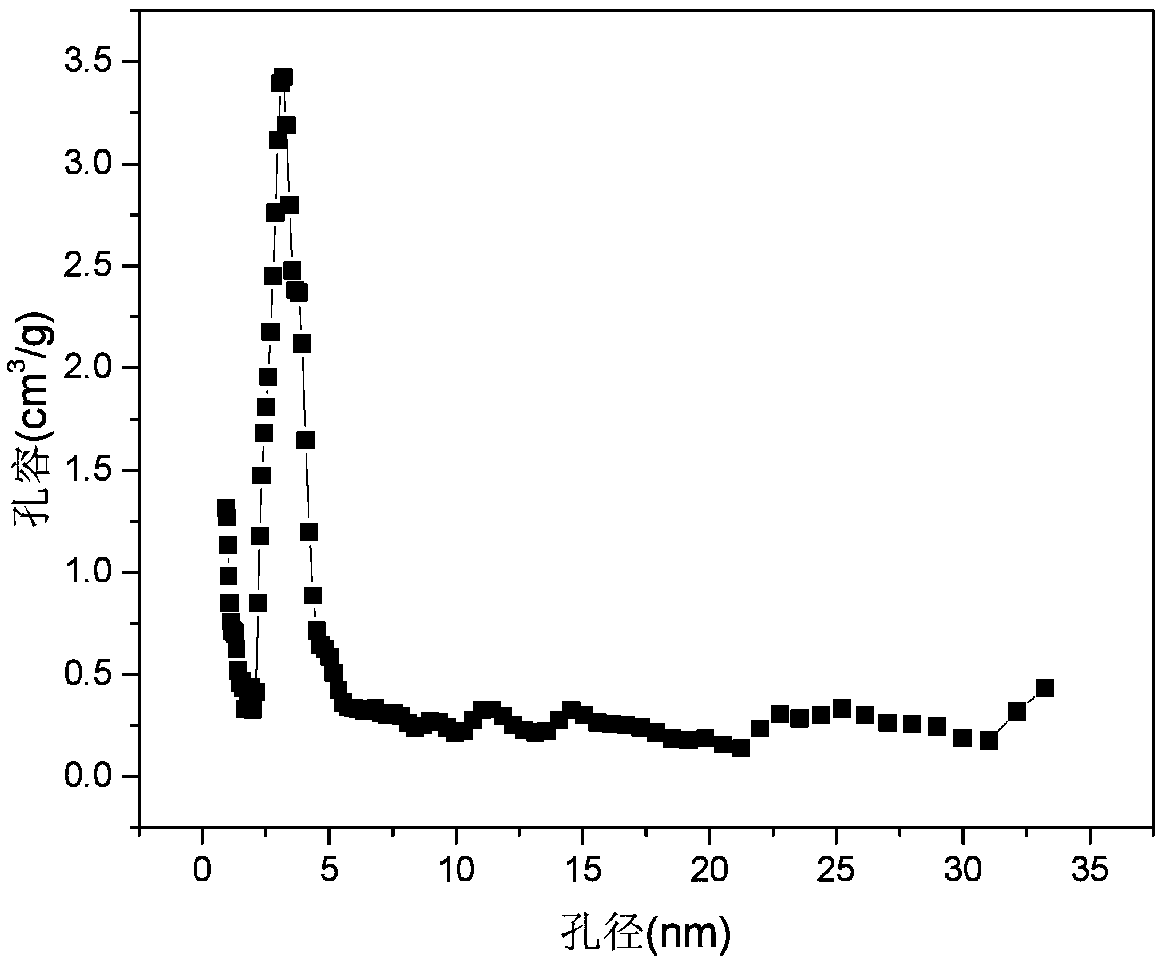

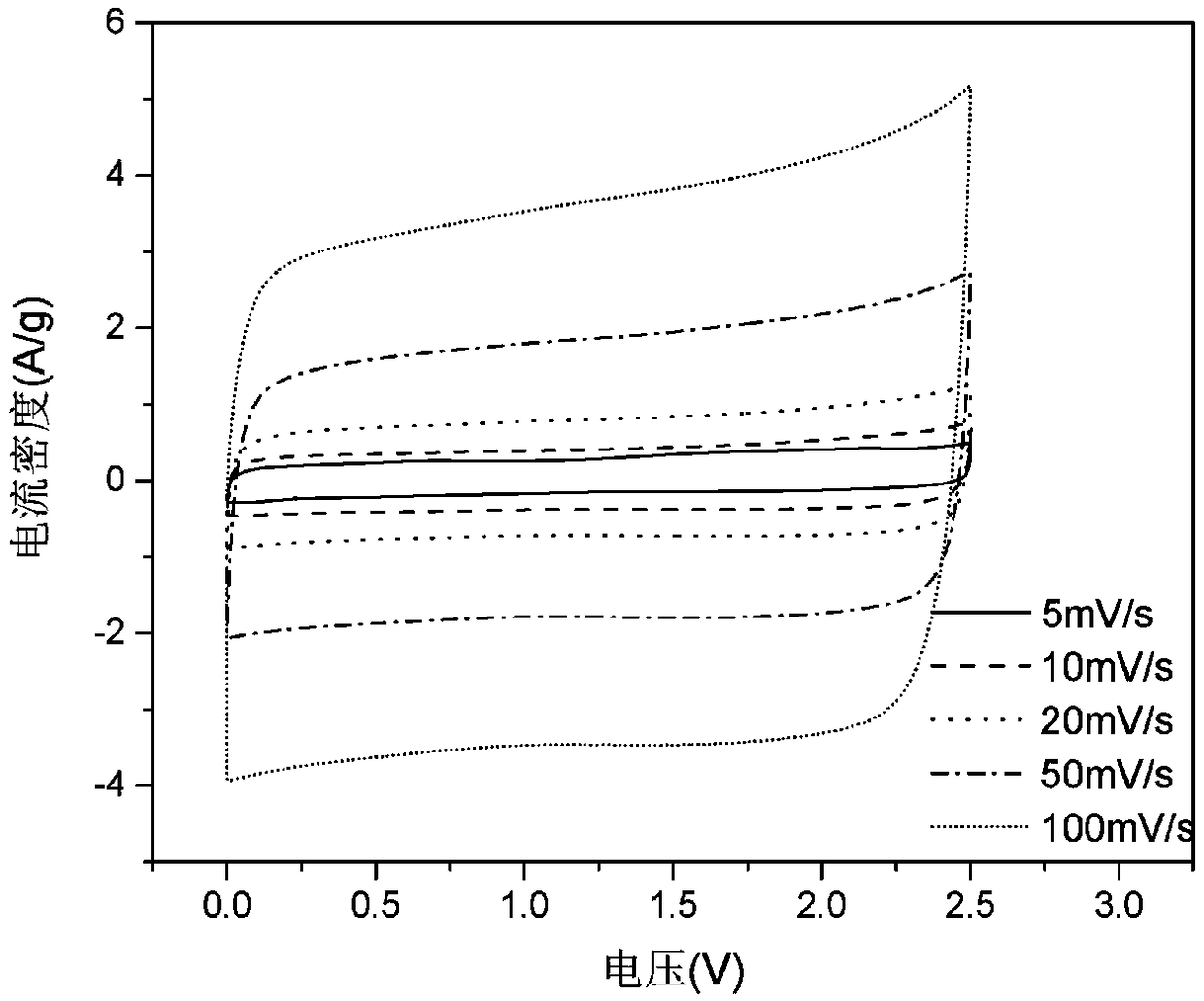

A supercapacitor and activated carbon technology, which is applied in the manufacture of hybrid/electric double layer capacitors, chemical instruments and methods, hybrid capacitor electrodes, etc., can solve the problems of low specific capacitance, high cost, and equipment corrosion of activated carbon, and achieve pore structure Developed, reasonable pore size distribution, and the effect of improving specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of activated carbon for supercapacitor, comprises the steps:

[0029] (1) Activate the carbonized material with the first gas to obtain the primary activated material; the temperature for the first gas activation is 800-950°C; the time for the first gas activation is 30-120 minutes;

[0030] (2) The primary activation material obtained in the step (1) is subjected to second gas activation, and the secondary activation material is obtained after cooling down; the temperature of the second gas activation is 800 to 1000°C, and the second gas activation The time is 30-180 minutes;

[0031] (3) the secondary activated material obtained in the step (2) is successively ground, washed and dried to obtain activated carbon for supercapacitor;

[0032] The activator for the first gas activation and the activator for the second gas activation independently include one or more of water vapor, carbon dioxide, air and ammonia, and t...

Embodiment 1

[0071] Place 300g of dried pine wood (1cm×1cm×15cm) in a carbonization furnace, heat up to 900°C at a rate of 10°C / min, and carbonize for 120min under nitrogen protection to obtain a carbonized material;

[0072] Weigh 15g of 900°C carbonized material and put it into an activation furnace for activation. During the temperature programming stage, nitrogen was introduced as a protective gas, and the heating rate was set at 10°C / min. When the actual temperature in the furnace reaches 850°C, turn off the nitrogen, and pass in water vapor at this temperature to activate for 60 minutes. After the water vapor activation is completed, turn off the water vapor, and immediately pass CO 2 gas. Then the activation furnace was heated up to 900°C at a rate of 10°C / min, activated at 900°C for 120min, CO 2 The flow rate is 0.2L / min. CO 2 After activation, cut off CO 2 The gas channel was immediately changed to nitrogen protection, and the activation furnace began to cool down naturally....

Embodiment 2~10

[0075] Examples 2-10 The preparation method of carbonized material and the activation method of carbonized material are the same as in Example 1, except that the parameters of the two gas activations are different, which are specifically listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com