Treatment technology for improving acoustic vibration characteristic of Paulownia tree wood

A technology of vibration characteristics and processing technology, which is applied in pretreatment equipment, wood processing equipment, impregnated wood, etc., can solve the problems of general acoustic vibration characteristics and limited use range, so as to improve the acoustic vibration characteristics, improve the quality constant of sound radiation, Effect of High Vibration Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

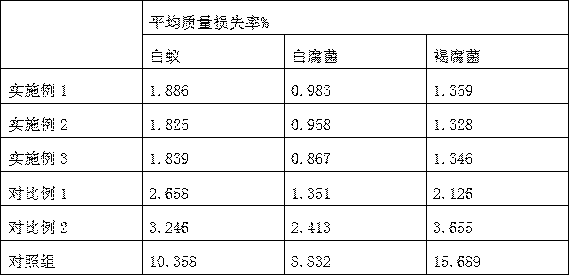

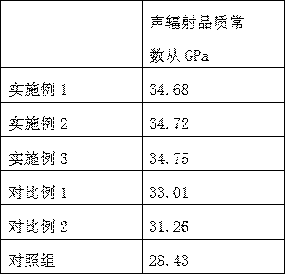

Examples

Embodiment 1

[0018] The invention discloses a treatment process for improving the acoustic vibration characteristics of paulownia wood. After the paulownia wood surface is polished, an oxidant solution is used to oxidize the paulownia wood surface, and then carbonized oil is used to carbonize the paulownia wood surface under vacuum conditions.

[0019] Further, the polishing of the paulownia surface is firstly using 500-mesh sandpaper to uniformly polish the paulownia surface for 15 minutes, and then using 800-mesh sandpaper to uniformly polish the paulownia surface for 25 minutes.

[0020] Further, the oxidizing treatment of paulownia wood surface with oxidant solution is to soak paulownia wood and oxidant solution at a ratio of 1kg:500mL, the soaking temperature is 78°C, the soaking time is 40min, and then dried at 100°C to the moisture content Up to 15%, that's all.

[0021] Further, the oxidant solution is a hydrogen peroxide solution with a mass fraction of 9.5%.

[0022] Further, th...

Embodiment 2

[0029] The invention discloses a treatment process for improving the acoustic vibration characteristics of paulownia wood. After the paulownia wood surface is polished, an oxidant solution is used to oxidize the paulownia wood surface, and then carbonized oil is used to carbonize the paulownia wood surface under vacuum conditions.

[0030] Further, the polishing of the paulownia surface is firstly using 500-mesh sandpaper to uniformly polish the paulownia surface for 20 minutes, and then using 800-mesh sandpaper to uniformly polish the paulownia surface for 30 minutes.

[0031] Further, the oxidizing treatment of paulownia wood surface with oxidant solution is to soak paulownia wood and oxidant solution at a ratio of 1kg:600mL, the soaking temperature is 80°C, the soaking time is 50min, and then dried at 100°C until the moisture content is reached Up to 15%, that's all.

[0032] Further, the oxidant solution is a hydrogen peroxide solution with a mass fraction of 9.8%.

[003...

Embodiment 3

[0040] The invention discloses a treatment process for improving the acoustic vibration characteristics of paulownia wood. After the paulownia wood surface is polished, an oxidant solution is used to oxidize the paulownia wood surface, and then carbonized oil is used to carbonize the paulownia wood surface under vacuum conditions.

[0041] Further, the polishing of the paulownia surface is firstly using 500 mesh sandpaper to uniformly polish the paulownia surface for 18 minutes, and then using 800 mesh sandpaper to uniformly polish the paulownia surface for 27 minutes.

[0042] Further, the oxidizing treatment of paulownia wood surface with oxidant solution is to soak paulownia wood and oxidant solution at a ratio of 1kg:550mL, the soaking temperature is 79°C, the soaking time is 45min, and then dried at 100°C to the moisture content Up to 15%, that's all.

[0043] Further, the oxidant solution is a hydrogen peroxide solution with a mass fraction of 9.6%.

[0044] Further, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com