An integral ceramic wire mesh corrugated packing and its manufacturing method

A technology of wire mesh corrugated packing and manufacturing method, applied in chemical instruments and methods, chemical/physical/physical chemical process, chemical/physical process, etc., can solve the problems of non-corrosion resistance, poor hydrophilic performance, etc. Compressive strength, high theoretical plate count, effect of reducing equipment construction and equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

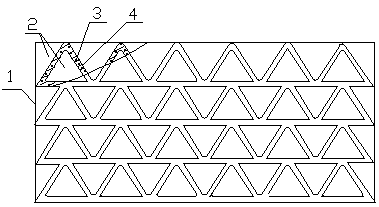

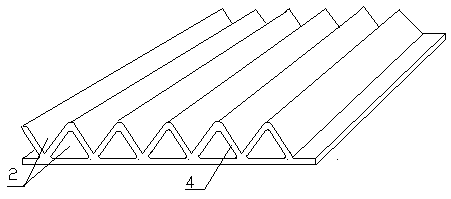

[0016] Example 1, such as figure 1 with figure 2 As shown, the integral ceramic wire mesh corrugated packing includes a packing body 1, and the packing body 1 is provided with corrugated holes 2 at intervals. The cross section of the holes is triangular, which can be circular, regular hexagonal or square. Formed with honeycomb hole 3 on the hole wall 4 between, it is manufactured by following method step:

[0017] a. Select different 100-200 meshes of cellular polyurethane sponge (cuboid, or cube), fix the sponge, and clamp the upper and lower sides of the sponge to a suitable degree of firmness with mechanical splints. The thickness of the sponge body, on the side of the thickness, according to the preset hole size and position and the number of rows of holes, to maintain a suitable hole wall thickness between the holes, the size, quantity and distribution of the triangular file and according to tightness The size, position and row number of the holes converted by the comp...

Embodiment 2

[0027] Embodiment 2, except that the slurry in embodiment 2 is different from the slurry proportioning in Example 1, other preparation methods are the same as in Example 1, and the slurry in Example 2: use calcined aluminum oxide powder 40wt %, silicon dioxide powder 40wt%, water-washed high-purity kaolin 10wt%, phosphoric acid with a concentration of 85% by weight 3wt%, potassium chloride 1wt%, white carbon black 2wt%, micron-sized ceramic reinforcing agent 2wt%, micron-sized Bentonite 2wt% and appropriate amount of water are mixed and ball milled to make a slurry.

[0028] The monolithic ceramic wire mesh corrugated filler performance index that embodiment 2 makes:

[0029] Compressive strength: 16.3MPa, bulk specific gravity: 201.5kg / m 3 ,

[0030] Specific surface area: 800m 2 / m 3 , porosity: 91%,

[0031] Density: 1.52g / cm3, acid and alkali resistance: 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com