Chicken silage capable of improving meat quality and preparation technology thereof

A chicken feed and silage technology, applied in the field of silage, can solve the problems of not promoting the decomposition of excess fat in broilers, affecting meat quality and taste, reducing chicken fat content, etc., so as to improve chicken flavor and color, reduce subcutaneous fat accumulation, and promote digestion. and absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

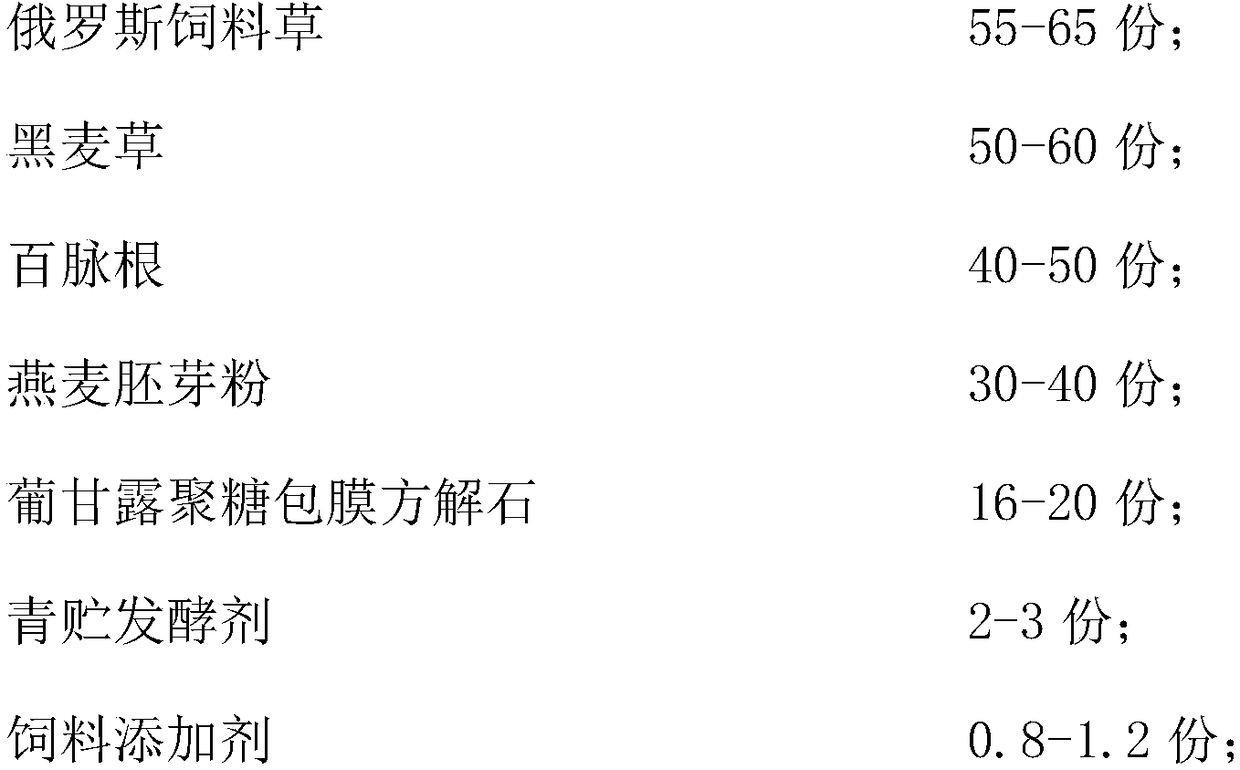

[0023] The silage chicken feed for improving meat quality includes the following ingredients by weight:

[0024]

[0025] Among them, the feed additives include the following components by weight percentage: Moringa seed oil 70%, lotus leaf alkali 6%, L-carnitine tartrate 3%, peppermint powder 10%, allicin 2%, sugar terpenin 4%, β -Carotene 0.8%, plant active selenium 0.1%, selenate polysaccharide 0.1%, choline chloride 4%.

[0026] The preparation process of the silage chicken feed with improved meat quality includes the following steps:

[0027] S1: Vacuum dry Russian fodder grass, ryegrass, and Lotus japonicus to a moisture content of 40%, and then crush them into a premix of 30mm length;

[0028] S2: Apply Lactobacillus plantarum to the premix. After mixing, compact until the volume of the premix is reduced by 55%, and covered with 6 layers of polyethylene film to create an oxygen-deficient environment. Perform the same type of lactic acid at 30°C Ferment, and squeeze the ferme...

Embodiment 2

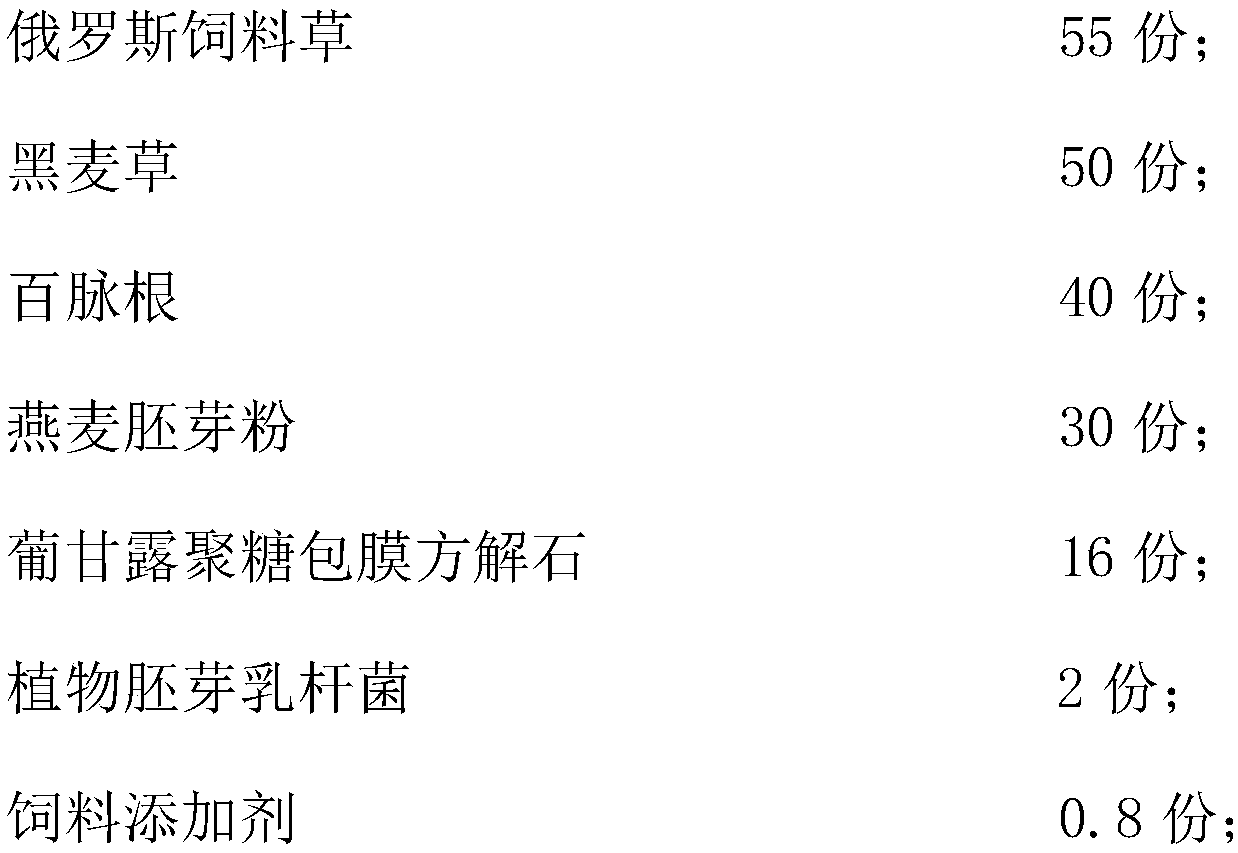

[0032] The silage chicken feed for improving meat quality includes the following ingredients by weight:

[0033]

[0034] Among them, the feed additives include the following components by weight percentage: Moringa seed oil 60%, lotus leaf 7%, L-carnitine tartrate 4%, peppermint powder 12.5%, allicin 3%, sugar terpenin 5%, β -Carotene 1%, plant active selenium 0.3%, selenate polysaccharide 0.2%, choline chloride 7%.

[0035] The preparation process is the same as in Example 1, the difference lies in:

[0036] S1: the water content is 45%, the length of the premix is 40mm; S2: the volume of the premix is reduced by 60%, the homolactic fermentation temperature is 33℃, the extrusion strength is 25MPa, and the bulk density is 800kg / m 3 ; S3: The swelling temperature is 45°C, and the average particle size of glucomannan-coated calcite is 1.3mm.

Embodiment 3

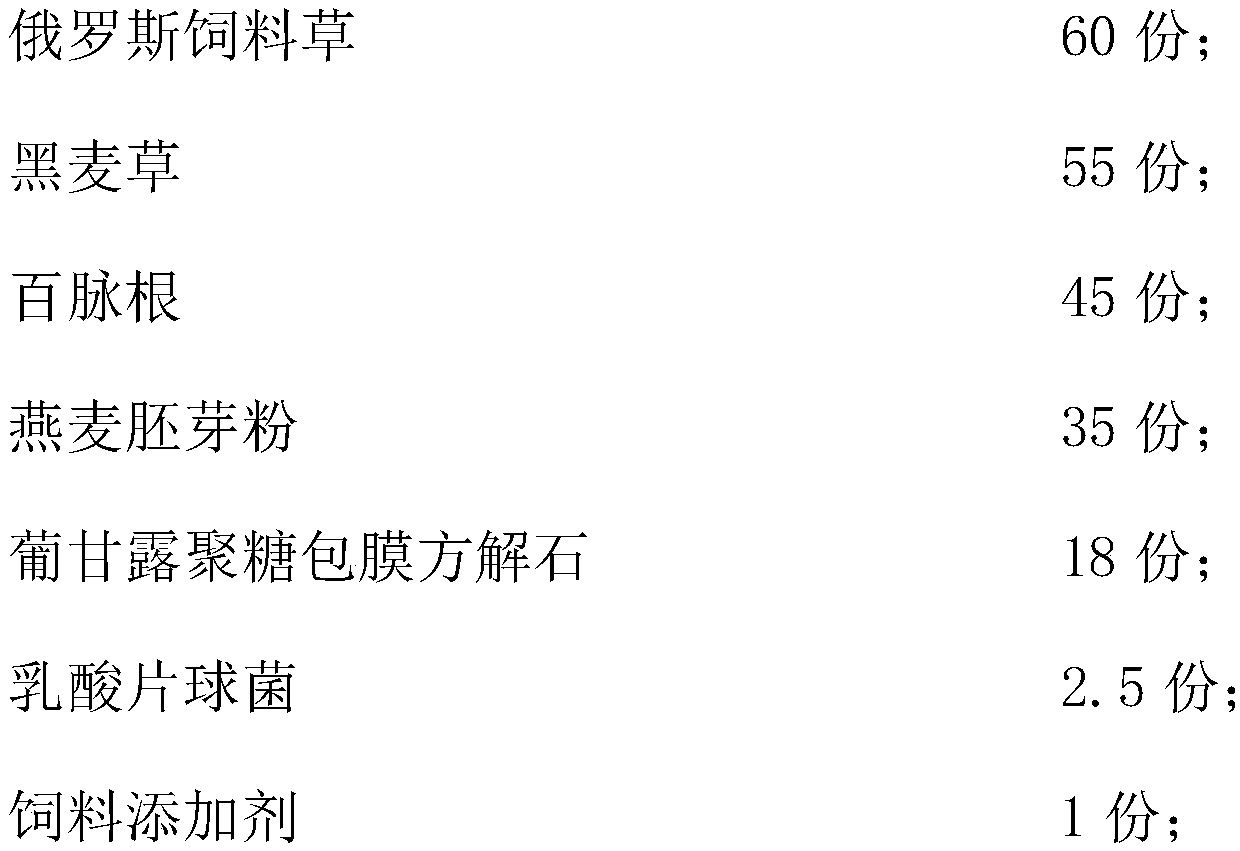

[0038] The silage chicken feed for improving meat quality includes the following ingredients by weight:

[0039]

[0040] Among them, the feed additives include the following components by weight percentage: Moringa seed oil 50%, lotus leaf alkali 8%, L-carnitine tartrate 5%, peppermint powder 15%, allicin 4%, sugar terpenin 6%, β -Carotene 1.2%, plant active selenium 0.5%, selenate polysaccharide 0.3%, choline chloride 10%.

[0041] The preparation process is the same as in Example 1, the difference lies in:

[0042] S1: The water content is 50%, the length of the premix is 50mm; S2: The volume of the premix is reduced by 65%, the homolactic fermentation temperature is 36℃, the extrusion strength is 30MPa, and the bulk density is 850kg / m 3 ; S3: The swelling temperature is 50°C, and the average particle size of glucomannan-coated calcite is 1.5mm.

[0043] Using ordinary silage as a comparative example, the chickens were continuously fed with the compound protein feed of Examples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com