Method of removing thiophene sulfides in fuel oil by adsorption of composite of Cu2O/SiO2-Al2O3-GO and aerogel

A technology of composite airgel and fuel oil, which is applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., to achieve the effect of enhancing strength, improving adsorption performance, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

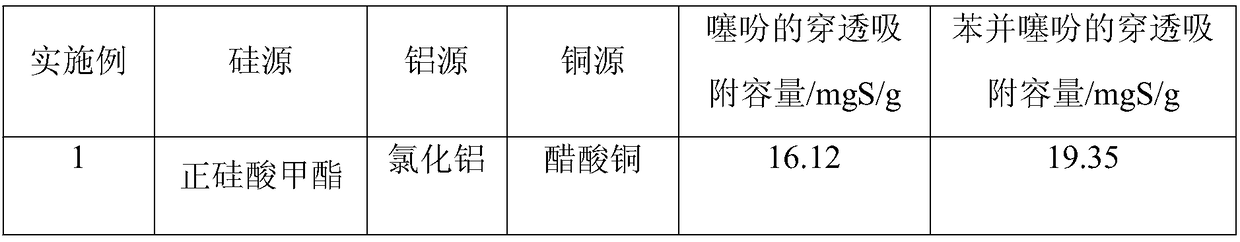

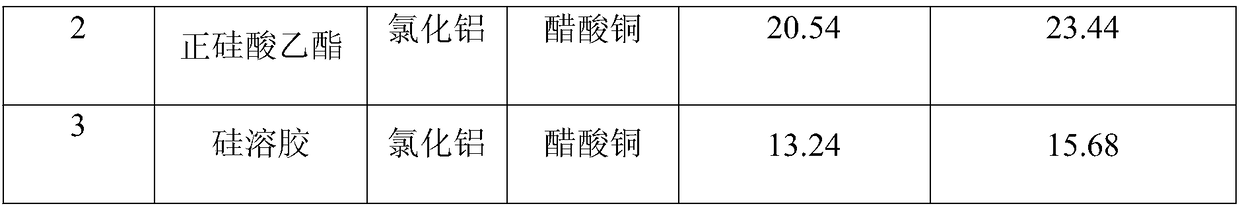

[0030] Examples 1-7: Cu with different silicon sources, aluminum sources, and copper sources 2 O / SiO 2 -Al 2 o 3 - Adsorption performance of graphene oxide composite airgel on thiophene sulfides in simulated gasoline

[0031] Cu with a silicon-copper molar ratio of 50, a silicon-aluminum molar ratio of 20, and a graphene oxide doping amount of 2‰ prepared by the sol-gel method 2 O / SiO 2 -Al 2 o 3 - In the graphene oxide composite airgel adsorbent, the silicon sources used include methyl orthosilicate, ethyl orthosilicate, and silica sol, the copper sources include copper nitrate and copper acetate, and the aluminum sources are aluminum nitrate and aluminum chloride (What is the reduction temperature and reduction time for preparing airgel here, because they are the influencing factors of the reaction, and the conditions should be clear). The prepared Cu 2 O / SiO 2 -Al 2 o 3 - Graphene oxide composite aerogel is used for penetration adsorption desulfurization experime...

Embodiment 8~12

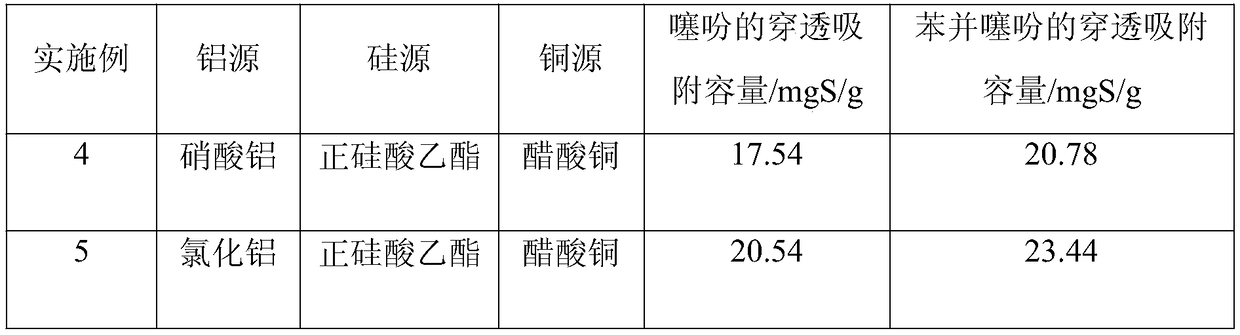

[0040] Examples 8-12: Cu with different silicon-aluminum molar ratios 2 O / SiO 2 -Al 2 o 3 - Adsorption performance of graphene oxide composite airgel on thiophene sulfides in simulated gasoline

[0041] The silicon-copper molar ratio is 50:1, the silicon-aluminum molar ratio is 5, 10, 20, 50, and 100 respectively, and Cu with a graphene oxide doping amount of 2‰ is selected. 2 O / SiO 2 -Al 2 o 3 - graphene oxide composite airgel adsorbent, other conditions are the same as the Cu of embodiment 2 2 O / SiO 2 -Al 2 o 3 - Graphene oxide composite aerogel, for penetration adsorption experiments on thiophene sulfides in simulated gasoline. The operation of the breakthrough adsorption experiment is the same as in Examples 1-7, and the adsorption results are shown in Table 4.

[0042] Table 4 Cu with different silicon-aluminum molar ratios 2 O / SiO 2 -Al 2 o 3 - Adsorption performance of graphene oxide composite airgel on thiophene sulfides in simulated gasoline

[0043] ...

Embodiment 13~17

[0045] Examples 13-17: Cu with different silicon-to-copper molar ratios 2 O / SiO 2-Al 2 o 3 - Adsorption performance of graphene oxide composite airgel on thiophene sulfides in simulated gasoline

[0046] Select Cu with silicon-copper molar ratio of 10, 20, 50, 70, 100, silicon-aluminum molar ratio of 20, and graphene oxide doping amount of 2‰ 2 O / SiO 2 -Al 2 o 3 - graphene oxide composite airgel adsorbent, other conditions are the same as the Cu of embodiment 2 2 O / SiO 2 -Al 2 o 3 - Graphene oxide composite aerogel, for penetration adsorption experiments on thiophene sulfides in simulated gasoline. The operation of the breakthrough adsorption experiment is the same as in Examples 1-7, and the adsorption results are shown in Table 5.

[0047] Table 5 Cu with different silicon-copper molar ratios 2 O / SiO 2 -Al 2 o 3 - Adsorption performance of graphene oxide composite airgel on thiophene sulfides in simulated gasoline

[0048]

[0049] It can be seen from Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com