Water reduction agent special for concrete prefabricated component

A technology of prefabricated components and water reducers, which is applied in the field of cement water reducers, and can solve the problems of inadaptability of cement and polycarboxylic acid to unloading of concrete, poor adaptability of naphthalene-based water reducers, and slump loss of concrete prefabricated components. , to achieve the effect of reducing the probability of shrinkage cracking, improving workability and durability, and improving surface brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

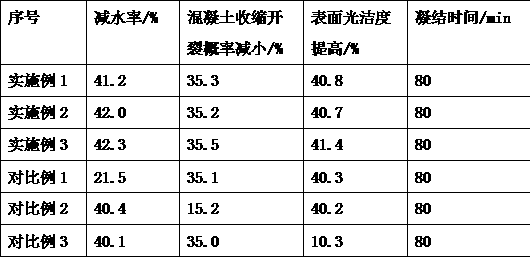

Examples

Embodiment 1

[0022] Example 1: Making a special water reducer for concrete precast components

[0023] The formula is: a special water reducer for precast concrete components, which is composed of the following components by weight: 14.5 parts of water reducer mother liquor, 0.013 parts of anti-cracking agent, 1.5 parts of methacrylic alcohol polyoxyethylene ether, sodium gluconate 2 parts, 0.003 parts of triterpene saponins, 0.02 parts of surface treatment agent, 0.03 parts of silicone defoamer, 82 parts of water, the mother liquor of water reducing agent is composed of the following components by weight: 5 parts of hydroxyethyl methacrylate , 20 parts of sodium methacrylate sulfonate, 12 parts of sodium dodecylbenzene sulfonate, the anti-cracking agent is characterized by reducing the probability of concrete shrinkage and cracking, and the surface treatment agent is used to improve the surface brightness of the concrete and reduce It is characteristic that the acid value of the methacrylic ...

Embodiment 2

[0031] Example 2: Making a special water reducer for concrete precast parts

[0032] The formula is: a special water reducer for precast concrete components, which is composed of the following components by weight: 16.5 parts of water reducer mother liquor, 0.015 parts of anti-cracking agent, 1.8 parts of methacrylic alcohol polyoxyethylene ether, and sodium gluconate 3 parts, 0.005 parts of triterpene saponins, 0.05 parts of surface treatment agent, 0.05 parts of polyether defoamer, 86 parts of water, the mother liquor of water reducing agent is composed of the following components by weight: 8 parts of hydroxyethyl methacrylate , 30 parts of sodium methacrylate sulfonate, 15 parts of sodium dodecylbenzene sulfonate, the anti-cracking agent is characterized by reducing the probability of concrete shrinkage and cracking, and the surface treatment agent is used to improve the surface brightness of the concrete and reduce It is characteristic that the acid value of the methacrylic ...

Embodiment 3

[0040] Example 3: Making a special water reducer for concrete precast components

[0041] The formula is: a special water reducer for precast concrete components, which is composed of the following components by weight: 15.5 parts of water reducer mother liquor, 0.014 parts of anti-cracking agent, 1.6 parts of methacrylic alcohol polyoxyethylene ether, and sodium gluconate 2.5 parts, 0.004 parts of triterpene saponins, 0.03 parts of surface treatment agent, 0.04 parts of polyether defoamer, and 84 parts of water. The water reducing agent mother liquor is composed of the following components by weight: 6 parts of hydroxyethyl methacrylate , 25 parts of sodium methacrylate sulfonate, 13 parts of sodium dodecylbenzene sulfonate, the anti-cracking agent is characterized by reducing the probability of concrete shrinkage and cracking, and the surface treatment agent is used to improve the surface brightness of the concrete and reduce Noodles are characteristic, the acid value of the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com