A composite concrete air-entraining agent, its preparation method and its application

A concrete and air-entraining agent technology, applied in chemical instruments and methods, dissolution, transportation and packaging, etc., can solve the problems of affecting the strength of concrete, general air-entraining effect, and insufficient amount of micro-bubbles, etc., to achieve significant foaming effect, Increased free surface area, strong bleed air effect

Active Publication Date: 2016-08-17

JIANGSU SOBUTE NEW MATERIALS +1

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the special environment of high salinity and high alkali inside the concrete, but the air-entraining effect of the existing air-entraining agent is average, and the amount of micro-bubbles is insufficient, so the addition of the air-entraining agent will affect the strength of the concrete. The invention provides a composite Type concrete air-entraining agent and preparation method thereof

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment A

[0058] Each embodiment A, B, C composition weight ratio and performance test result are shown in table 4, table 5 and figure 1 .

[0059] Table 4 A, B, C composition and weight ratio

[0060]

[0061]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

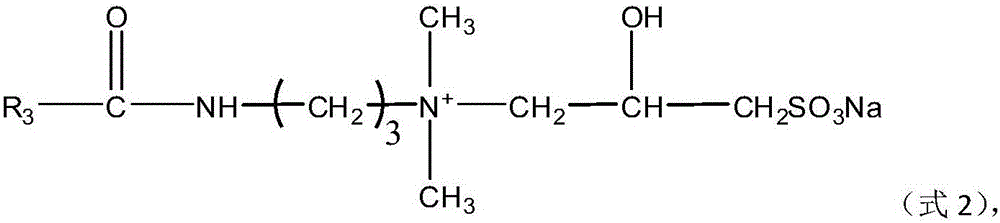

Login to View More Abstract

The invention provides a composite concrete air-entraining agent, its preparation method and its application, characterized in that: the composite concrete air-entraining agent consists of sulfonate type gemini surfactant, betaine type amphoteric surfactant, alkane Alcohol amide type non-ionic surfactant and water; the solid content of the composite concrete air-entraining agent is 20±1%. The composite concrete air-entraining agent of the present invention has an excellent air-entraining effect in concrete, introduces a sufficient amount of 20-150 μm stable micro-bubbles, improves the workability of concrete (mortar), reduces bleeding rate and settlement, and While increasing the air content, it does not reduce the later strength of concrete.

Description

technical field [0001] The invention belongs to the technical field of building materials, and in particular relates to a composite concrete air-entraining agent capable of significantly improving the durability of concrete and a preparation method thereof. Background technique [0002] The freeze-thaw damage and salt freeze damage of concrete buildings and various structures, roads and marine engineering have always been the focus of people's attention. Studies have shown that adding an appropriate amount of air-entraining agent in the concrete preparation process, introducing and retaining an appropriate amount of air bubbles with small sizes and reasonable structures in the concrete is the most important measure to greatly improve the freeze-thaw cycle resistance of concrete and increase the durability index. [0003] The commonly used chemical air-entraining agents in the field of concrete mainly include modified rosin sulfonate, alkyl sulfonate, alkyl polyoxyethylene et...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01F17/00C09K23/00

Inventor 冉千平高南箫乔敏刘加平

Owner JIANGSU SOBUTE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com