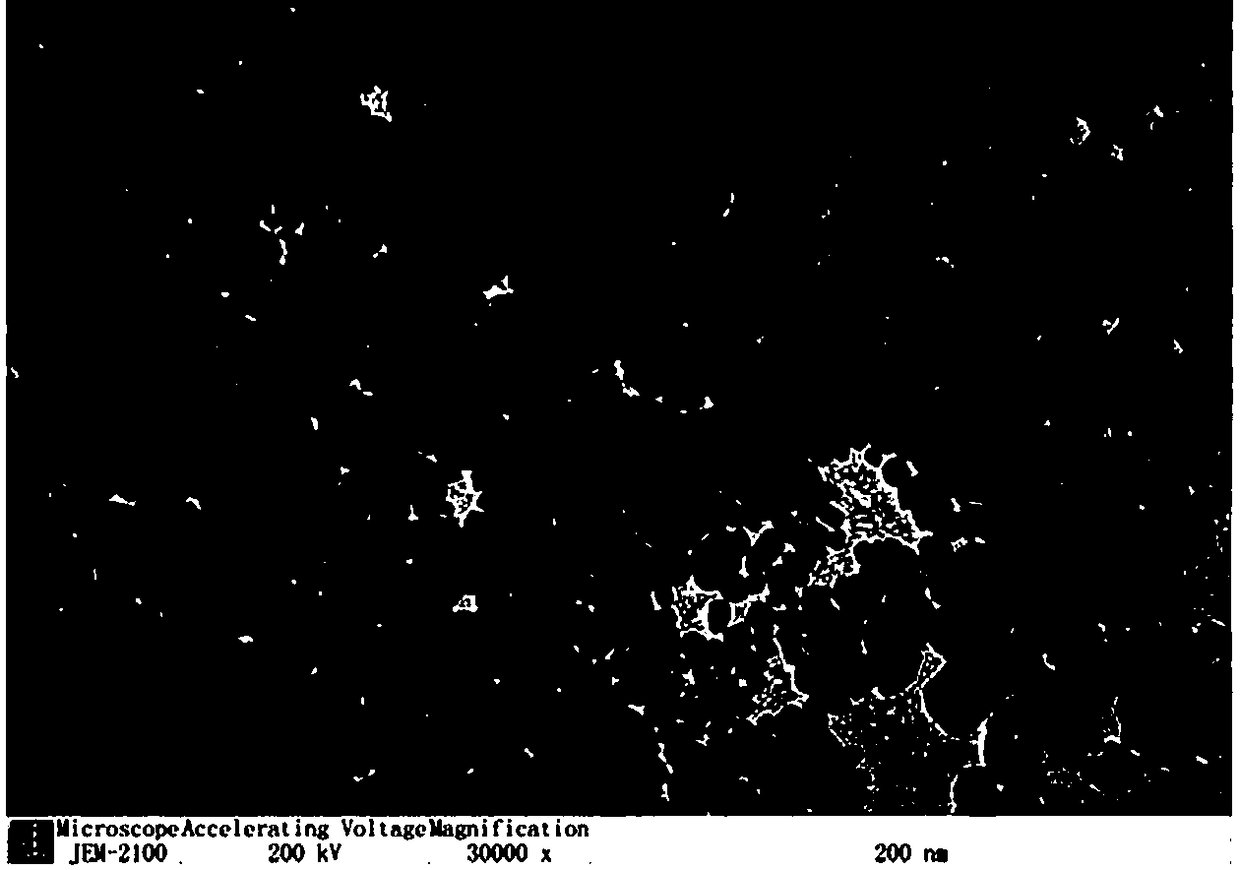

Method for efficiently preparing nano barium sulfate with uniform particles

A technology of nano-barium sulfate and uniform particles, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. Simple process, no magnification effect, fine appearance and size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1. First, weigh the raw BaS ore and add it to deionized water at 80°C, stir it with a magnetic stirrer to accelerate dissolution, and then filter to obtain a BaS solution with a concentration of 1 mol / l. Dilute 98% concentrated sulfuric acid into a dilute sulfuric acid solution with a concentration of 1mol / l;

[0043] Step 2. Pump the dilute sulfuric acid and BaS solutions in step 1 into the microreactor in the hot water bath at 70°C at a flow rate of 50 mL / min, and react in the microreactor for 1 s. The barium sulfate product is collected at the outlet of the device and the NaOH solution that produces toxic gas is absorbed;

[0044] Step 3. The product in step 2 is subjected to high-speed centrifugation, washing, and the speed of the centrifuge is 10000 r / min. Wash 5 times with alcohol until the washing liquid is neutral, stop the centrifugal washing, and remove the centrifuged product and transfer it to an oven. Dry at low temperature for 5 hours, and the oven t...

Embodiment 2

[0047] Step 1. First weigh the raw BaS ore and add it to deionized water at 80°C, stir it with a magnetic stirrer to accelerate the dissolution, and then filter to obtain a BaS solution with a concentration of 1 mol / L. Dilute 98% concentrated sulfuric acid into a dilute sulfuric acid solution with a concentration of 1 mol / L;

[0048] Step 2. Pump the dilute sulfuric acid and BaS solutions in step 1 into the microreactor in the 80°C hot water bath at a flow rate of 100 mL / min, respectively, and react in the microreactor for 0.5 s. The barium sulfate product is collected at the outlet of the device and the NaOH solution that produces toxic gas is absorbed;

[0049] Step 3, the product in step 2 is subjected to high-speed centrifugation, washing, and the centrifuge speed is 12000 r / min, and is washed 8 times with alcohol until the washing liquid is neutral to stop centrifugation and washing, and the centrifuged product is removed and transferred to Dry in an oven at low temperat...

Embodiment 3

[0052] Step 1. First weigh the raw BaS ore and add it to deionized water at 80°C, stir it with a magnetic stirrer to accelerate the dissolution, and then filter to obtain a BaS solution with a concentration of 0.5 mol / L. Dilute 98% concentrated sulfuric acid into a dilute sulfuric acid solution with a concentration of 0.5mol / l;

[0053] Step 2. Pump the dilute sulfuric acid and BaS solutions in step 1 into the microreactor in the hot water bath at 60°C at a flow rate of 50 mL / min, and react in the microreactor for 1 s. The barium sulfate product is collected at the outlet of the device and the toxic gas is absorbed and treated with NaOH solution;

[0054] Step 3. The product in step 2 is subjected to high-speed centrifugation, washing, and the centrifuge speed is 8000 r / min. Wash with deionized water for 6 times until the washing liquid is neutral, stop the centrifugal washing, and remove the centrifuged product. Dry in an oven at a low temperature for 5 hours at a temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com