Ultrahigh-impact-toughness high-purity-degree steel for low temperature pressure vessel and production method thereof

An impact toughness and pressure vessel technology, applied in the field of high-purity low-temperature pressure vessel steel, can solve the problem of difficulty in meeting the requirements of strength and toughness stably, and achieve the effects of excellent comprehensive mechanical properties, improved cleanliness, high and low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

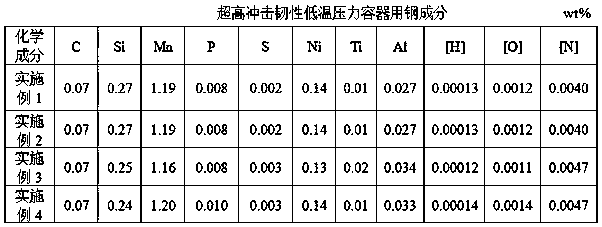

[0045] Such as figure 2 Shown, the chemical composition of the present invention is compared with the chemical composition of 09MnD steel.

[0046] And according to the following method to produce 4 sets of examples:

[0047] 1) Converter smelting: smelting in a top-bottom combined blowing converter of more than 100 tons, using molten iron and high-quality scrap steel as raw materials for preliminary smelting, to achieve pre-de-P removal, and adding synthetic refining slag, composite deoxidizer and a variety of high purity to the steel The alloy is pre-deoxidized and the composition is initially adjusted, and the sliding plate is used to block slag to keep the steel from tapping to prevent back to P;

[0048] 2) Refining: deep deoxidation and alloying of molten steel in an LF furnace of more than 100 tons, making a refined slag with a basicity slag R=5~8, and strengthening the removal of S and removing inclusions through the steel slag reaction; stirring throughout the refining proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com