Radiation waste boiler system and working method thereof

A waste boiler and water-cooled wall technology, applied in gasification process, chemical industry, petroleum industry, etc., can solve the problem of high system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] like Figure 1~3 As shown, the present embodiment provides a radiation waste pot system, which includes:

[0077] A casing 51, on which a syngas / gas outlet 52 is arranged, and a radiation waste pot and a purge assembly are arranged inside the casing 51;

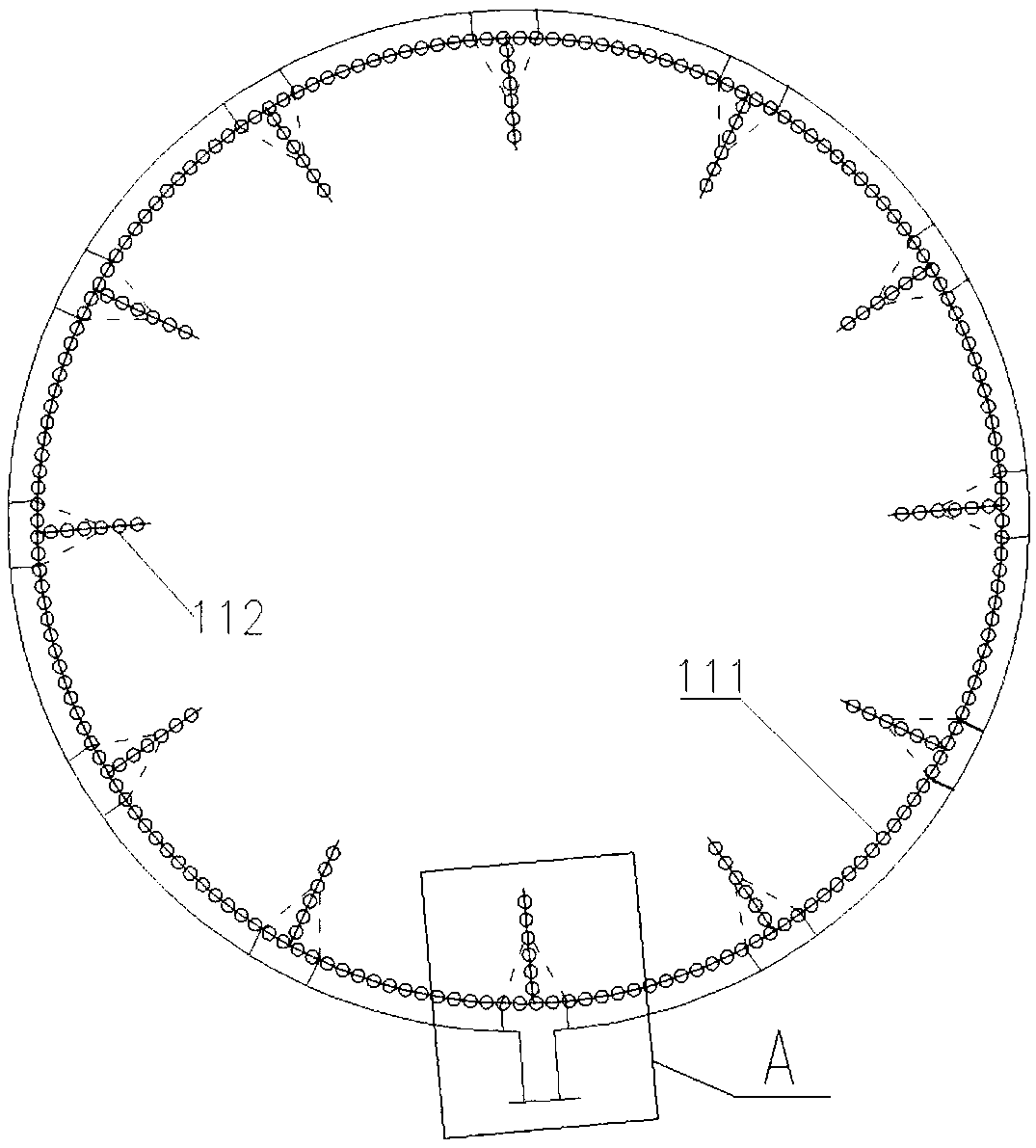

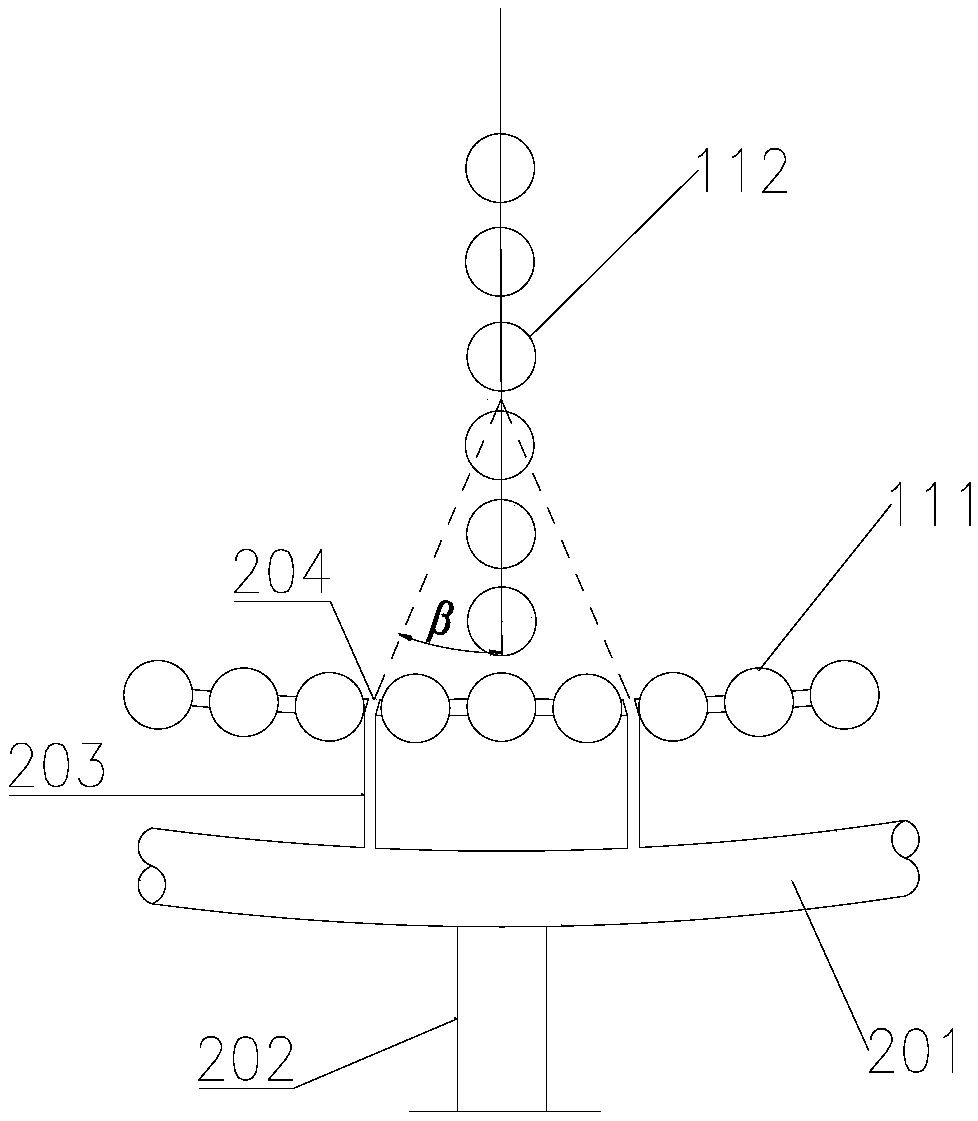

[0078] Radiation waste pot, the upper and lower parts of the radiation waste pot are respectively provided with an inlet 12 and an outlet 13, and the straight section 11 is surrounded by a cylinder water cooling wall 111, and a plurality of sets of radial water cooling walls are arranged radially inside the cylinder water cooling wall 111. wall 112;

[0079] The purge assembly is provided with at least one purge gas ring pipe 201 on the outer side of the water wall 111 of the cylinder, and the purge gas ring pipe 201 communicates with the purge gas inlet pipe 202 on the outside and several purge gas branch pipes 203 on the inside in turn One end of the purge gas branch pipe 203 communicates with the purge gas ring pi...

Embodiment 2

[0099] like Figure 4 As shown, on the basis of Embodiment 1, the radiation waste boiler system of this embodiment also includes a monitoring component, which includes a number of thermocouples 31 and a flow meter 32, and the thermocouples 31 are used to measure the cylinder water wall 111 and / or Or the surface temperature of the radial water cooling wall 112, the temperature of the cooling water entering the cylinder water cooling wall 111 and / or the radial water cooling wall 112, and the steam temperature of the cylinder water cooling wall 111 and / or the radial water cooling wall 112 steam drum, the flowmeter 32 is used to measure the flow of cooling water entering the cylinder water wall 111 and / or the radial water wall 112 and the steam output of the steam drum 41 .

[0100] The radiant waste pot also includes a steam drum 41, which is used to separate saturated steam and water generated in the cylindrical water-cooled wall 111 and / or the radial water-cooled wall 112.

[...

Embodiment 3

[0119] A multi-nozzle opposed coal-water slurry gasification device for the production of chemicals, in which the daily processing scale of the gasifier is 1500t / d, and the high-temperature gas flow rate from the gasifier into the radiant waste pot is about 190,000Nm 3 / h, the temperature is 1340°C, the ash flow rate is 6800kg / h (the ash content is about 30%), and the pressure is 6.5MPa. In order to recover the sensible heat carried by the high-temperature gas, a radiant waste boiler system shown in Embodiment 2 is arranged at the bottom of the gasification chamber, wherein,

[0120] The inner diameter of the shell 51 is 4200mm, the inner diameter D of the lining of the cylindrical water-cooled wall 111 is 3200mm, the height of the straight section 11 is 22m, the number of radial water-cooled walls 112 is 16, and the inner diameter of the radial water-cooled wall 112 is 2600mm. The SiC layer stacked on the inner wall of the lower cone section water cooling wall 132 is 16mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com