Electromagnetically enhanced continuous fermentation method and device

A technology of electromagnetic strengthening and fermentation method, which is applied in fertilization devices, applications, organic fertilizers and other directions to achieve the effects of reducing harmful substances, improving the quality of compost products, and improving the activity of biological enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

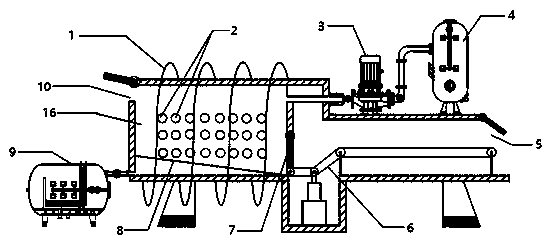

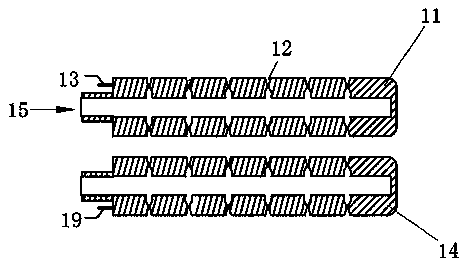

[0033] Example 1: This electromagnetic enhanced continuous fermentation method treats cow manure. The cow manure is fed from the feed port into a fermentation chamber uniformly equipped with an array of hollow perforated electrode pairs. The fermentation raw material is cut through the hollow perforated electrode pair and then placed on the hollow perforated electrode Between the pairs, the air is blown into the fermentation raw materials through the hollow perforated electrode pair to aerate the fermentation raw materials to ensure that the fermentation raw materials in different stages are in a fully and evenly mixed state. The electrochemical action in the fermentation process produces free radicals, and at the same time heavy metals are transformed into soluble forms from the fermentation raw materials and move out into the fermentation broth through electrochemical action, and the positively charged heavy metal ions are enriched in the hollow perforated electrode pair. On ...

Embodiment 2

[0037] Embodiment 2: Electromagnetic enhanced continuous fermentation method for processing kitchen waste. The method and device of this embodiment are the same as in Embodiment 1, the difference is that the through hole is a Venturi tube structure, the diameter of the throat section is 0.5mm, and the air inlet of the through hole The aperture is 2mm, the aperture of the air outlet of the through hole is 1mm, the density of the through holes on the hollow perforated electrode pair is 20 / cm², the hollow perforated electrode pairs are distributed in an equidistant array, and the interval between the cathode electrode 14 and the anode electrode 11 is 30cm, The distance between hollow perforated electrode pairs is 20cm, the inclination angle of the filter plate is 15°, the aperture of the filter plate is 8mm, the material of the filter plate is stainless steel, the thickness of the filter plate is 15mm, the anode electrode is a cerium tungsten electrode, and the cathode electrode is...

Embodiment 3

[0040] Embodiment 3: The electromagnetic enhanced continuous fermentation method treats sewage treatment plant sludge. The method and device of this embodiment are the same as in Embodiment 1, the difference is that the through hole is a Venturi tube structure, the diameter of the throat section is 3mm, and the air intake of the through hole The hole diameter is 5 mm, the gas outlet diameter of the through hole is 4.5 mm, the density of through holes on the hollow perforated electrode pair is 5 / cm², the hollow perforated electrode pairs are distributed in an equidistant array, and the interval between the cathode electrode 14 and the anode electrode 11 is 10cm, the distance between hollow perforated electrode pairs is 30cm, the inclination angle of the filter plate is 30°, the aperture of the filter plate is 10mm, the material of the filter plate is stainless steel, the thickness of the filter plate is 5mm, and the electrode is brass electrode;

[0041] After adding 1200Kg of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com