Light epoxy foam-based sandwich plate and preparation method thereof

A technology of epoxy foam and sandwich panels, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of destroying the strength of the honeycomb core, multiple layers of the sandwich panel structure, and affecting the mechanical properties. Achieve the effects of improving impact damage resistance, good heat insulation and noise reduction performance, and improving structural specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

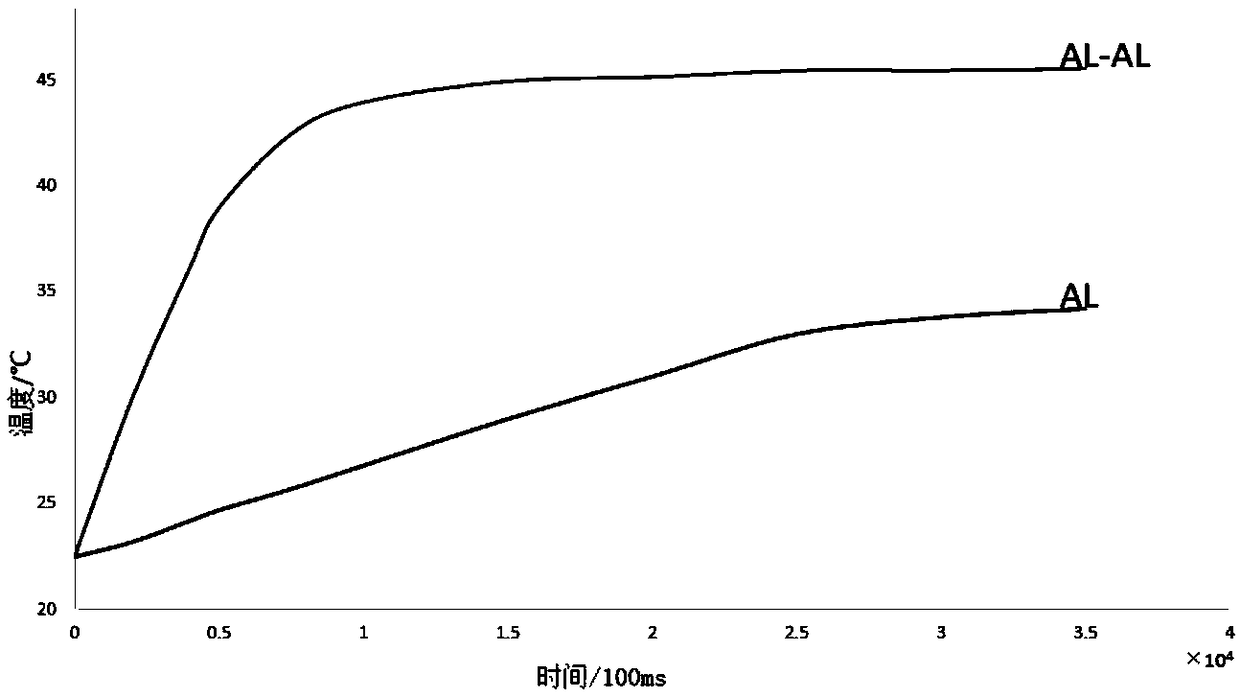

[0033] The epoxy foam base sandwich panel structure of the present embodiment is as follows figure 2 As shown, there are outer skin 1, epoxy foam core 2 and inner skin 3 from outside to inside. The outer skin 1 and the inner skin 3 are made of aluminum alloy, and the thickness of the aluminum alloy is 1.5mm. The thickness of the epoxy foam core 2 is 30 mm.

[0034] The epoxy foam core 2 is formed by foaming the epoxy foam-based composite material, and the epoxy foam-based composite material includes by weight: Component A: 100 parts of NPEL-128, 3 parts of acetic acid, 1.6 parts of expandable microbeads Matsumoto F36L , 0.5 parts of KH-560; B component: 45 parts of Versamid 125, 5 parts of EC301, 4 parts of ammonium bicarbonate, 3 parts of coated red phosphorus, and 3 parts of resorcinol.

[0035] Preparation of epoxy foam-based sandwich panels: (1) Place the inner and outer skins of the same height in the mold vertically close to the mold wall and fix them. The height of t...

Embodiment 2

[0037] The epoxy foam base sandwich panel structure of the present embodiment is as follows figure 2 As shown, there are outer skin 1, epoxy foam core 2 and inner skin 3 from outside to inside. The outer skin 1 and the inner skin 3 are steel plates with a thickness of 1.5 mm. The thickness of the epoxy foam core 2 is 30mm.

[0038] The epoxy foam core 2 is formed by foaming the epoxy foam-based composite material, and the epoxy foam-based composite material includes by weight: Component A: 100 parts of NPEL-127, 5 parts of acetic acid, 1.5 parts of expandable microbeads Matsumoto F48 , 0.5 parts of KH-560; B component: 50 parts of Versamid 140, 7 parts of sodium bicarbonate, 3 parts of APP, 3 parts of 2,4,6-tris(dimethylaminomethyl)phenol.

[0039] Preparation of epoxy foam-based sandwich panels: (1) Place the inner and outer skins of the same height in the mold vertically close to the mold wall and fix them. The height of the mold is the same as or slightly lower than that...

Embodiment 3

[0041] The epoxy foam base sandwich panel structure of the present embodiment is as follows figure 2 As shown, there are outer skin 1, epoxy foam core 2 and inner skin 3 from outside to inside. The outer skin 1 is made of aluminum alloy, and the thickness of the aluminum alloy is 2 mm. The epoxy foam core 2 has a thickness of 10mm. The inner skin 3 is a steel plate, and the thickness of the steel plate is 0.15mm.

[0042] The epoxy foam core 2 is formed by foaming the epoxy foam-based composite material, and the epoxy foam-based composite material includes by weight: Component A: 100 parts of NPEL-144, 2.5 parts of acetic acid, and 1 part of expandable microbeads Matsumoto F36L , 1 part of A-171; B component: 15 parts of TEPA, 3.5 parts of sodium bicarbonate, 4 parts of aluminum hydroxide, 3 parts of 2,4,6-tris(dimethylaminomethyl)phenol.

[0043] Preparation of epoxy foam-based sandwich panels: (1) Place the inner and outer skins of the same height in the mold vertically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com