Prefabricated concrete sandwich insulation wall board connecting piece and connecting method

A technology of prefabricated concrete and thermal insulation wall panels, which is applied to walls, building components, buildings, etc., can solve the problems of complex manufacturing process of connecting parts, complicated processing and manufacturing of connecting parts, poor connection strength and rigidity, etc., and achieve low production cost, Good thermal resistance, good connection strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

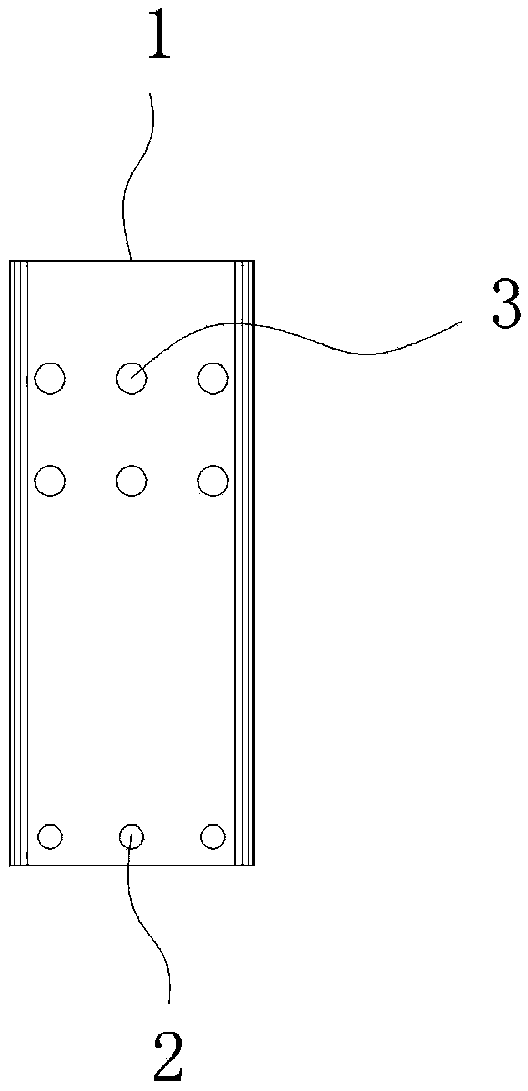

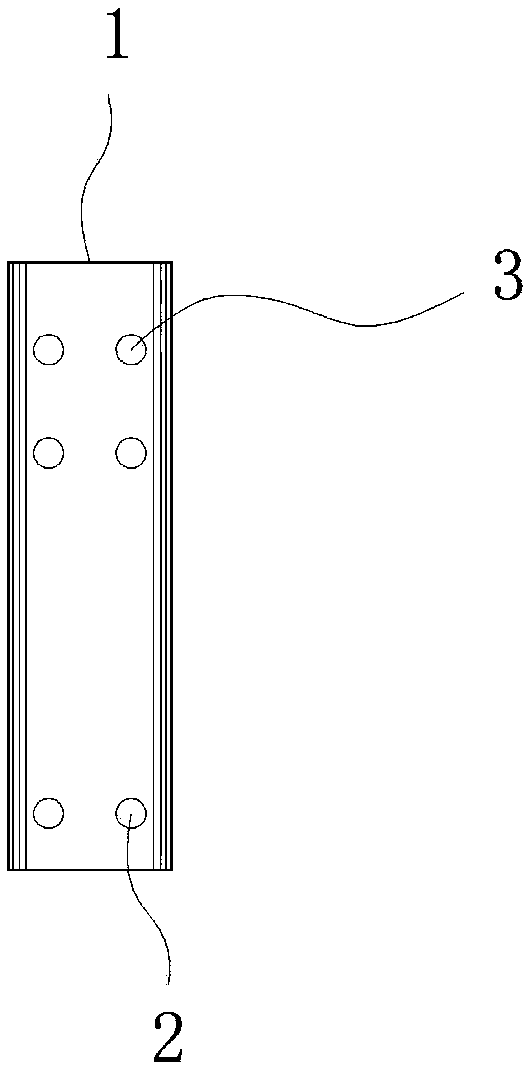

[0044] A prefabricated concrete sandwich insulation wall panel connector, such as Figure 1 ~ Figure 4 , Figure 6 ~ Figure 13 As shown, it includes: a connecting piece 1, an outer leaf plate connecting steel bar 5 and an inner leaf plate connecting steel bar 9, the cross section of the connecting piece 1 is square, and the connecting piece 1 is made of carbon fiber, aramid fiber, polyethylene fiber or basalt fiber. The high-strength fiber pipe obtained by pre-impregnating resin and heating and curing. The connecting piece 1 is provided with an outer hole 2 and an inner hole 3. The outer hole 2 is opened in the middle of the corresponding outer leaf plate; The position of the leaf plate is opened; the outer leaf plate connecting steel bar 5 is set to one or more than one, and is arranged in the outer leaf plate concrete 6 through the outer hole 2, and the inner leaf plate connecting steel bar 9 is set to one or one Above the root, pass through the inner hole 3 and set in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com