A kind of liquid phase preparation method of regenerated rubber

A technology of reclaimed rubber and liquid phase, applied in the production of bulk chemicals, plastic recycling, recycling technology, etc., can solve the problems of low Mooney viscosity tensile properties, increased hardness and Mooney viscosity, limited penetration, etc. The effect of uniform and stable reaction degree, prevention of oxidative degradation and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

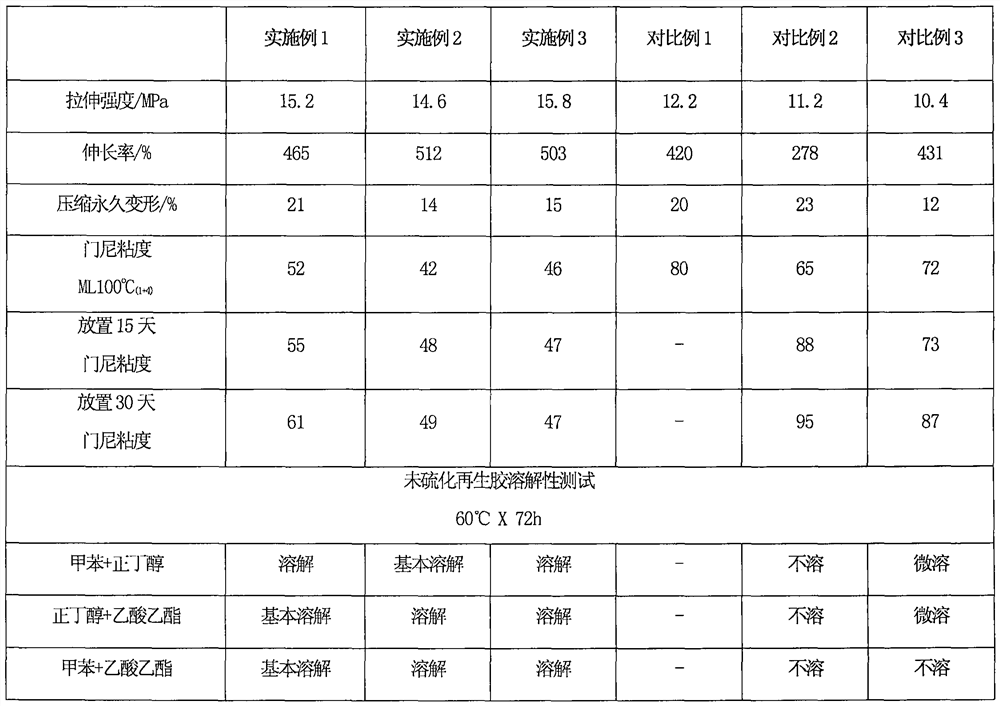

Examples

Embodiment 1

[0027] The present embodiment provides a liquid-phase preparation method of regenerated rubber, comprising the steps of:

[0028] Add 1 weight part of dibromoethane and 1-bromopropane into 70 weight parts of a mixed solvent of 4-pentadecylphenol and phenol tar, and stir at 70°C until it is completely dissolved to obtain regeneration system a; Add 1 part by weight of 2-methyl-5-phenylpentane-2-mercaptan to 45 parts by weight of a mixed solvent of 3-pentadecylphenol and o-dichlorobenzene, and stir at 75°C until regenerated The chemical agent was completely dissolved to obtain the regeneration system b; 1 part by weight of sodium tert-butoxide was added to 20 parts by weight of a mixed solvent of 3-pentadecylphenol and octadecadecyl hexadecyl ether, and stirred at 35°C Until the regeneration activator is completely dissolved, the regeneration system c is obtained;

[0029] Add 50-mesh waste tread rubber powder and an organic extractant consisting of nitroethane, acetophenone, he...

Embodiment 2

[0036] The present embodiment provides a liquid-phase preparation method of regenerated rubber, comprising the steps of:

[0037] Add 1 weight part of dibromoethane and 1-bromopropane into 55 weight parts of a mixed solvent of 4-pentadecylphenol and phenol tar, and stir at 45°C until it is completely dissolved to obtain regeneration system a; Add 1 part by weight of 2-methyl-5-phenylpentane-2-mercaptan to 50 parts by weight of a mixed solvent of 3-pentadecylphenol and o-dichlorobenzene, and stir at 50°C until regenerated The chemical agent was completely dissolved to obtain regeneration system b; 1 part by weight of sodium tert-butoxide was added to 22 parts by weight of a mixed solvent of 3-pentadecylphenol and stearyl hexadecyl ether, and stirred at 28°C Until the regeneration activator is completely dissolved, the regeneration system c is obtained;

[0038] Add 100-mesh waste tread rubber powder, nitroethane, acetophenone, hexane, and xylene as an organic extraction aid to...

Embodiment 3

[0045] The present embodiment provides a liquid-phase preparation method of regenerated rubber, comprising the steps of:

[0046] Add 1 weight part of dibromoethane and 1-bromopropane into 80 weight parts of a mixed solvent of 4-pentadecylphenol and phenol tar, and stir at 45°C until it is completely dissolved to obtain regeneration system a; Add 1 part by weight of 2-methyl-5-phenylpentane-2-mercaptan to 60 parts by weight of a mixed solvent of 3-pentadecylphenol and o-dichlorobenzene, and stir at 50°C until regenerated The chemical agent was completely dissolved to obtain regeneration system b; 1 part by weight of sodium tert-butoxide was added to 30 parts by weight of a mixed solvent of 3-pentadecylphenol and stearyl hexadecyl ether, and stirred at 30°C Until the regeneration activator is completely dissolved, the regeneration system c is obtained;

[0047] Put 150-mesh waste tread rubber powder, nitroethane, acetophenone, hexane, and xylene into the supercritical reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com