A photochromic material with fast response time and wide response range and preparation method thereof

A technology of photochromic materials and response range, which is applied in the direction of color-changing fluorescent materials, organic chemical methods, chemical instruments and methods, etc., to achieve the effects of environmental friendliness, easy availability of raw materials, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this example, 0.081g of zinc oxide, 0.104g of lithium fluoride and 0.510g of hydroxyethylidene diphosphonic acid monohydrate were added to a 20mL polytetrafluoroethylene-lined stainless steel reactor and dissolved in 5mL of water, and 0.05 g TPT, after fully stirring, seal the stainless steel reaction kettle with the reaction solution, and crystallize it in an oven at 145°C for 7 days. After the reaction is completed, take out the stainless steel reaction kettle and let it cool naturally at room temperature. The crystals were removed and washed repeatedly with deionized water for 5 times, and dried at room temperature to obtain colorless rod-like crystals.

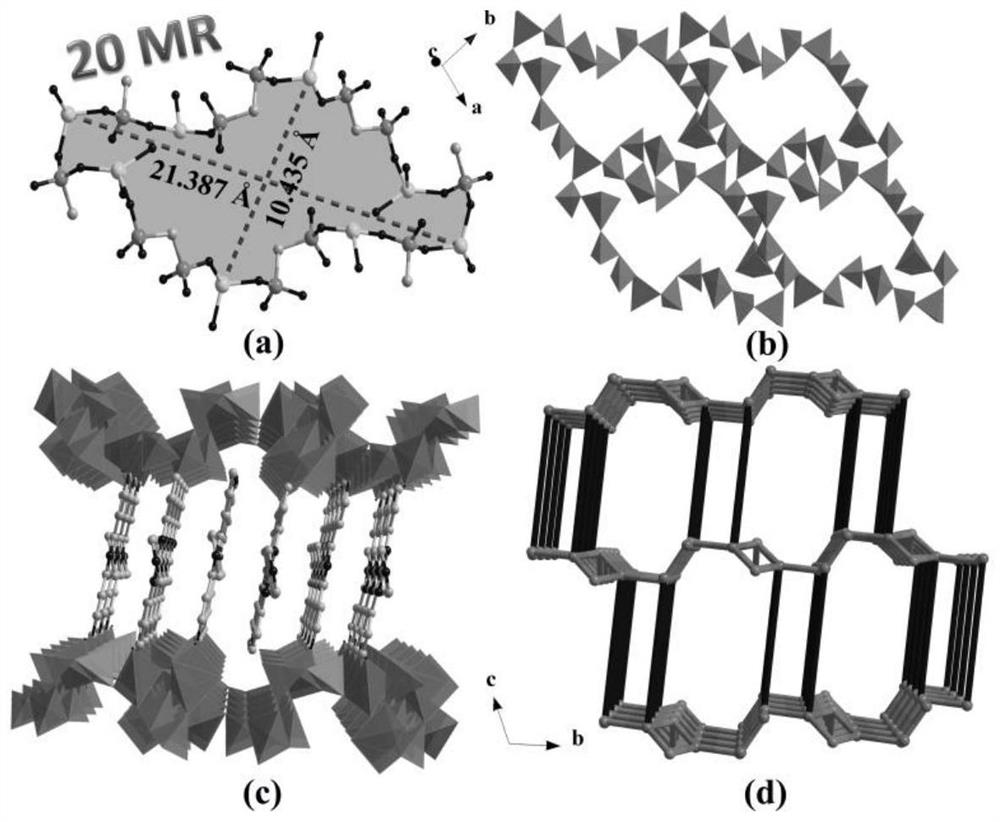

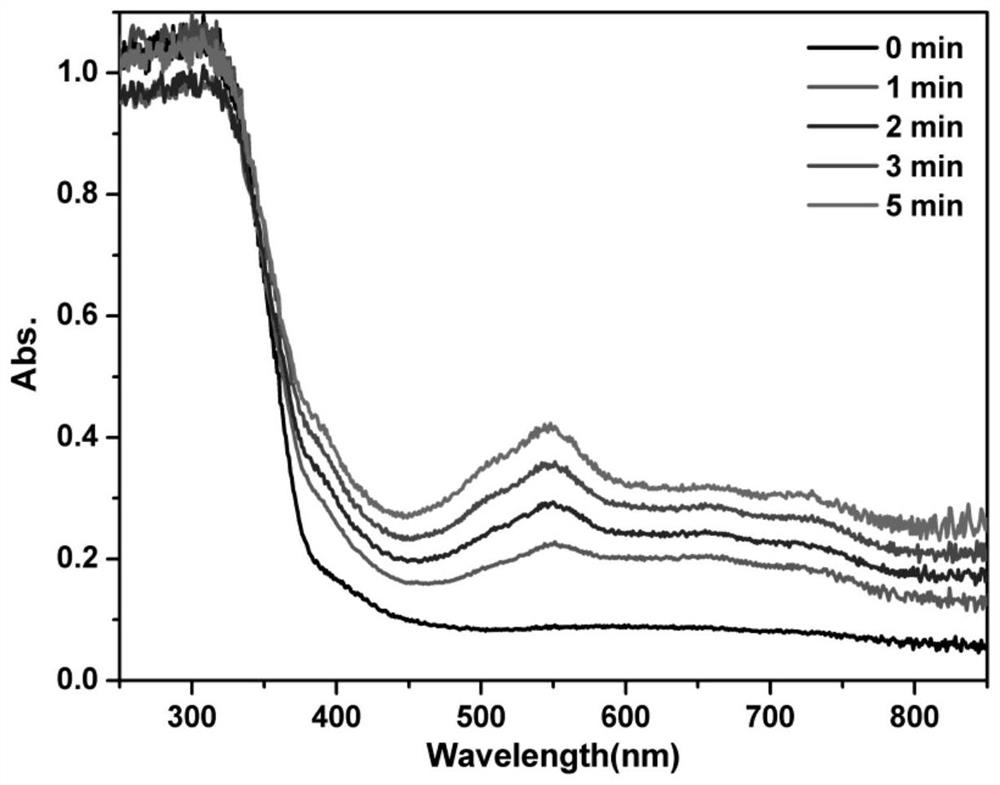

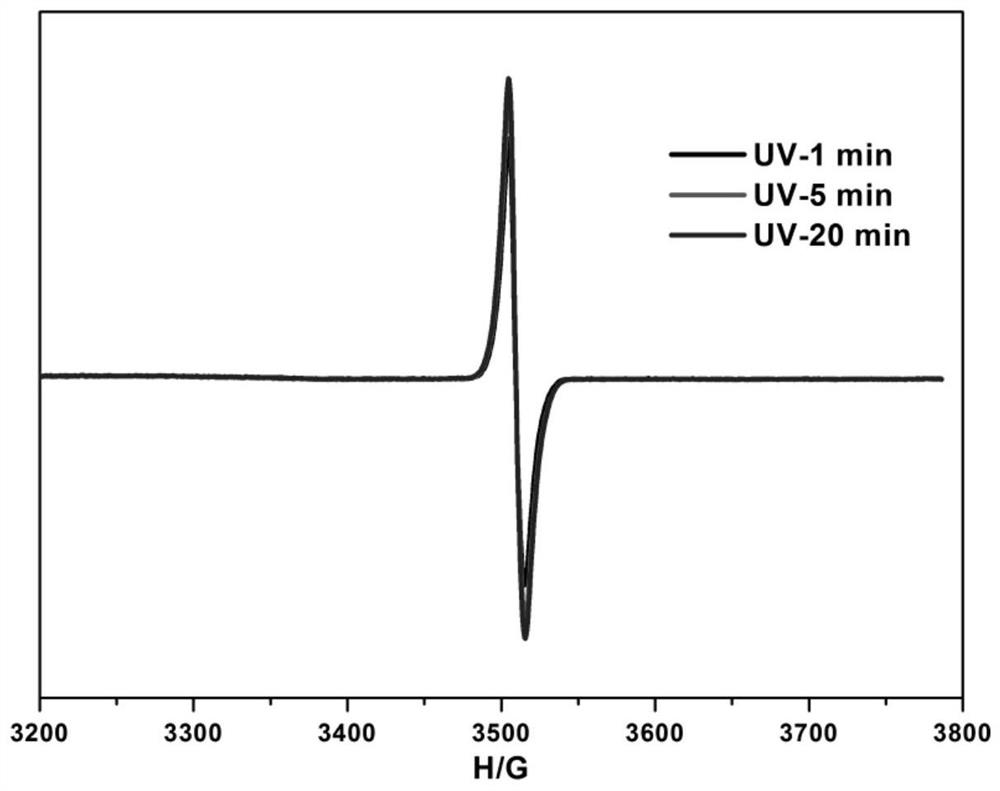

[0027] In this example, a single crystal diffraction test was carried out on the prepared colorless rod-shaped crystals, and the data analysis showed that the obtained compound had a 3D layered columnar structure, in which HEDP chelated-bridged Zn 2+ A 2D layer is formed, and the terminal TPT ligand passes throug...

Embodiment 2

[0029] In this example, 0.081g of zinc oxide and 0.104g of lithium fluoride were added to a 20mL polytetrafluoroethylene-lined stainless steel reactor and dissolved in 5mL of water, and 0.55mL of hydroxyethylidene diphosphonic acid (60% aqueous solution) was added while stirring. And 0.05gTPT, after fully stirring, the stainless steel reaction kettle that reaction liquid is housed is sealed, crystallizes in the oven of 145 ℃ for 7 days, after the completion of the reaction, through the method of cooling, washing and drying as in Example 1, the obtained The characteristics and results of the target product are the same as in Example 1.

Embodiment 3

[0031] In this embodiment, 0.081g of zinc oxide and 0.189g of oxalic acid dihydrate were added to a 20mL polytetrafluoroethylene-lined stainless steel reactor and dissolved in 5mL of water, and 0.15mL of hydroxyethylidene diphosphonic acid (60% aqueous solution) was added while stirring. ) and 0.05g TPT, after fully stirring, the stainless steel reaction kettle with the reaction solution was sealed, crystallized in an oven at 145°C for 7 days, after the reaction was completed, through the methods of cooling, washing and drying as in Example 1, The various characterizations and results of the target product obtained are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com