Method for conversion of dry powder for synthesis of porous composite framework material

A technology of skeleton materials and synthesis methods, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as increased environmental pollution, reduced yield, increased cost, etc., and achieves low operating costs and reaction promotion Large force, reduced operating energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

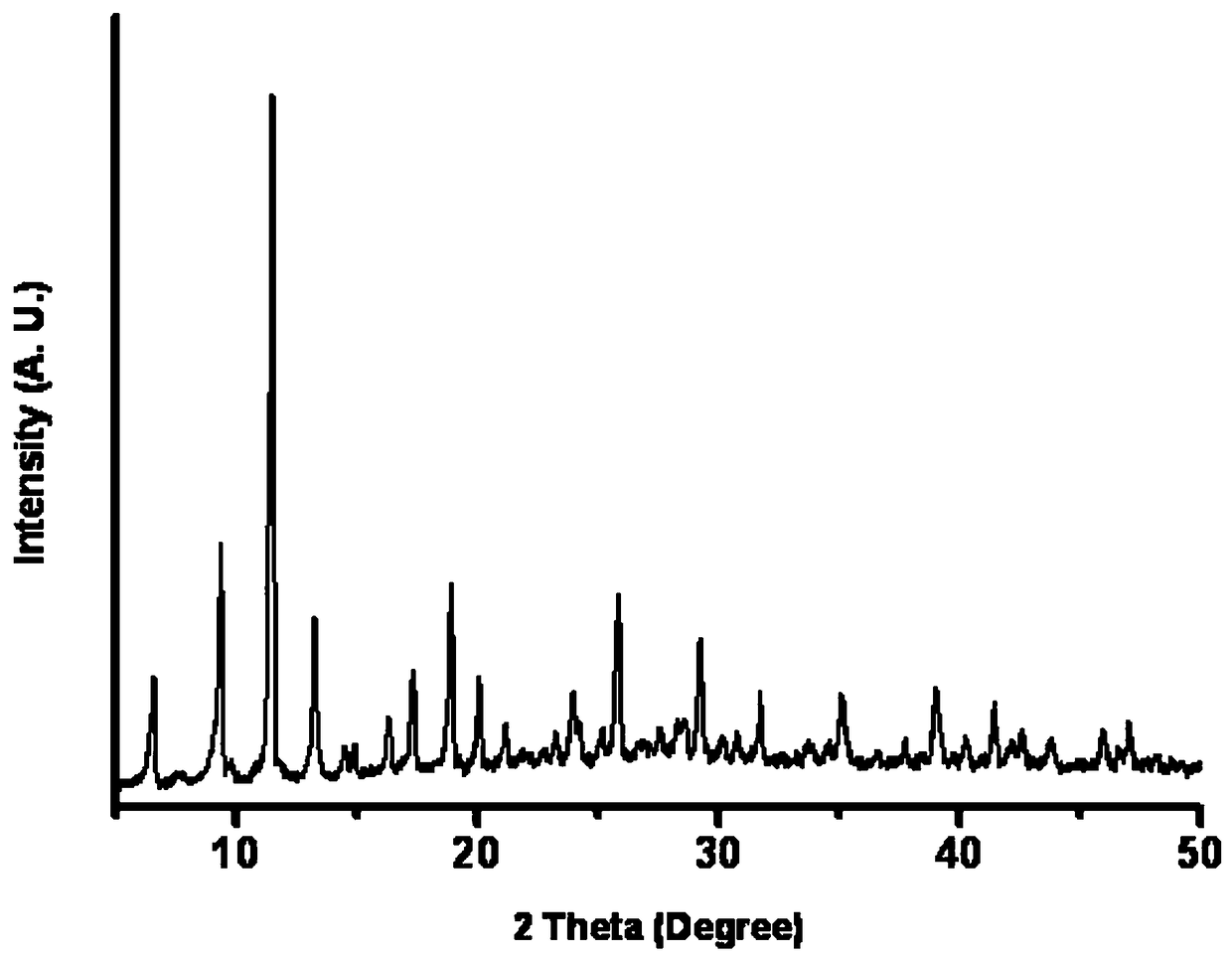

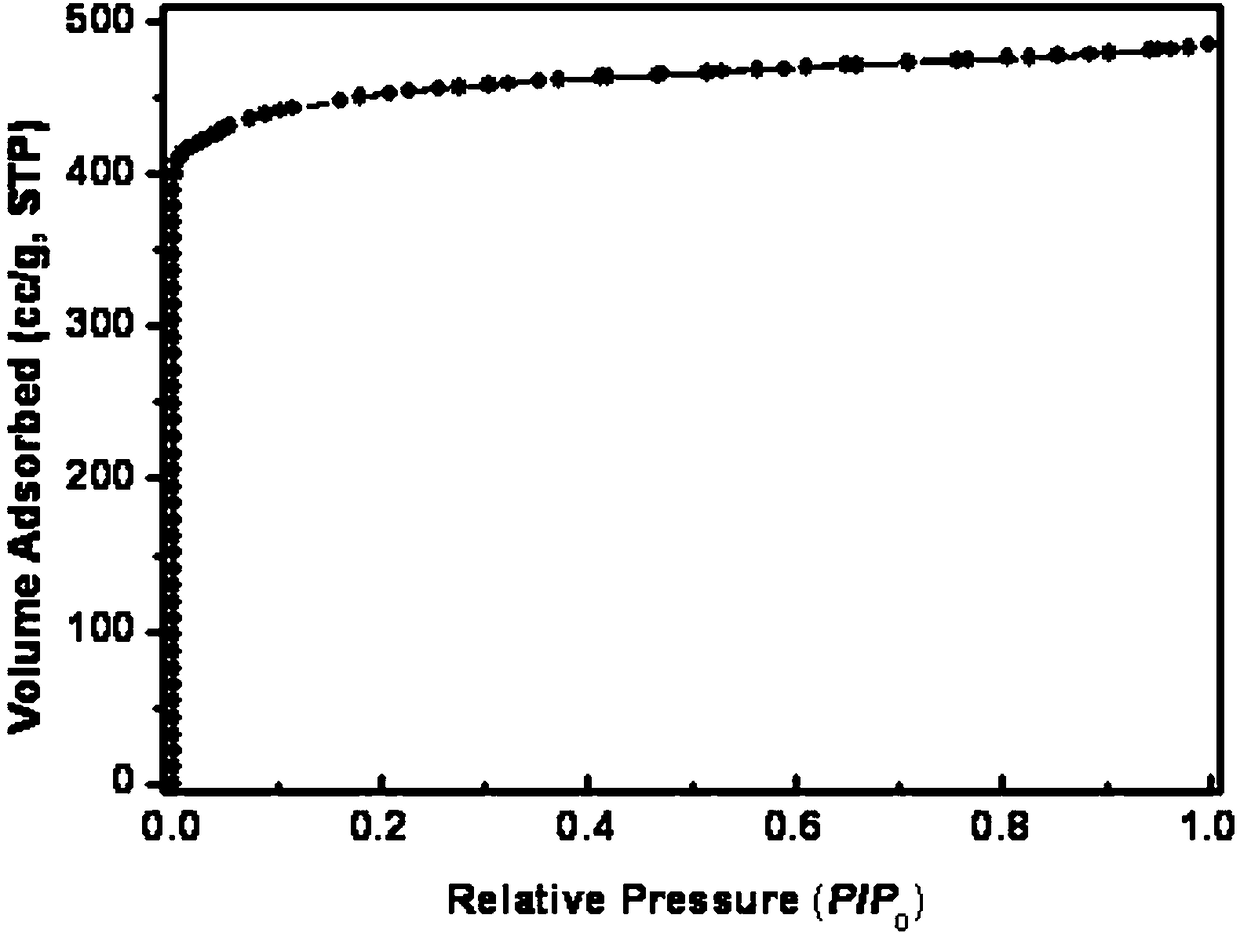

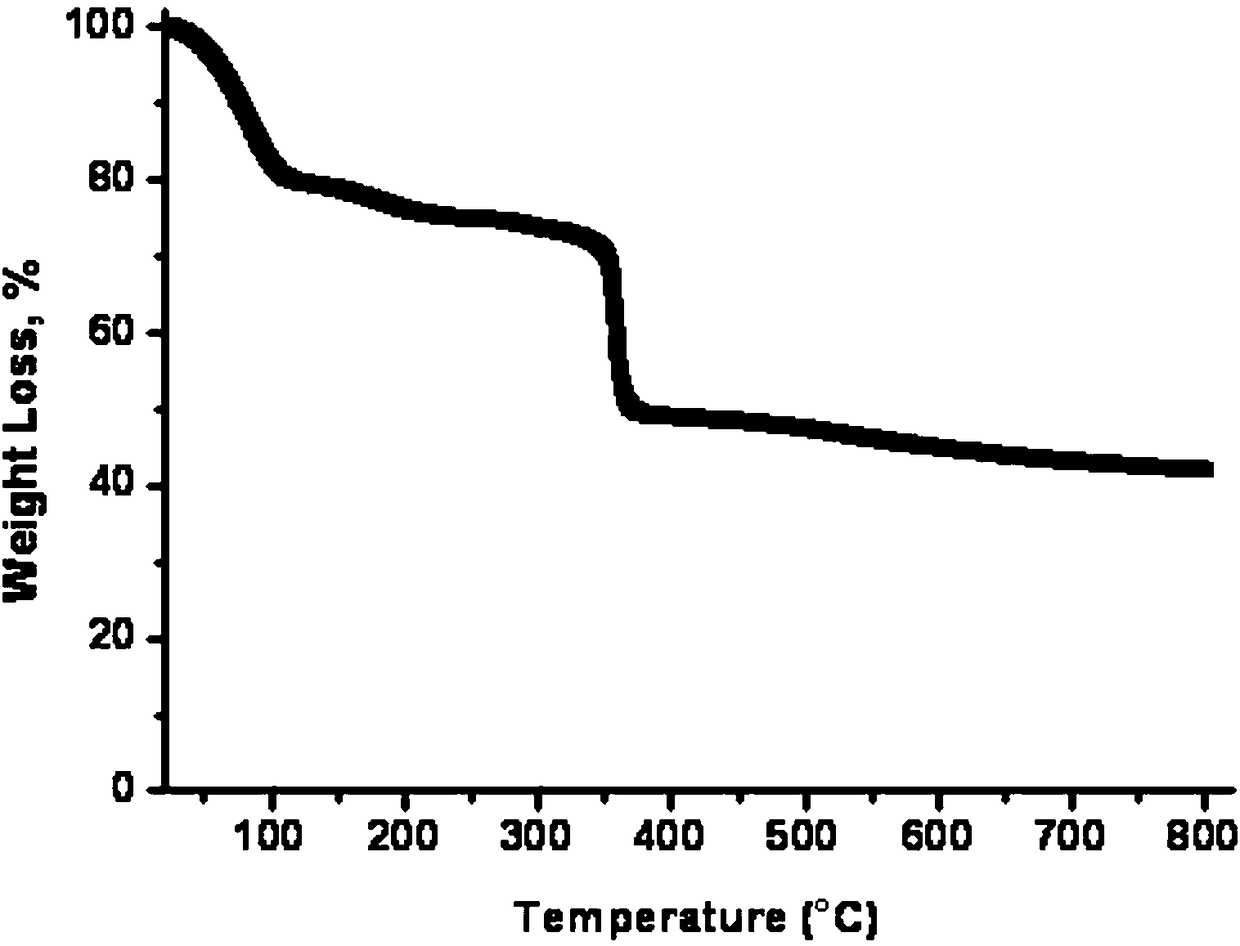

Image

Examples

Embodiment 1

[0016] Example 1: A method of dry powder conversion to synthesize a porous composite framework material. Copper nitrate trihydrate is the coordination metal source in the porous composite framework material, and trimesic acid is the ligand of the porous composite framework material. Accurately weigh 0.0061 One mole of copper nitrate trihydrate and 0.004 mole of trimesic acid, the molar ratio of coordination metal source to ligand is 3.05:2, mix copper nitrate trihydrate and trimesic acid at room temperature and grind and stir for 10 minutes to form a dry material , and then transfer the mixed material into a polytetrafluoroethylene container with a height of about 30 mm.

[0017] Add 2ml of deionized water and 1.4ml of ethanol at the bottom of the reaction kettle with a volume of 100ml; put the polytetrafluoroethylene container containing the reaction materials into the reaction kettle, the dry materials in the reaction kettle will not be in direct contact with the liquid phase...

Embodiment 2

[0019] Example 2: A method of dry powder conversion to synthesize a porous composite framework material, copper carbonate is the coordination metal source in the porous composite framework material, trimesic acid is the ligand of the porous composite framework material, and 0.0061 moles of carbonic acid are accurately weighed respectively Copper and 0.004 moles of trimesic acid, the molar ratio of the coordination metal source and the ligand is 3.05:2, copper carbonate and trimesic acid are ground separately at room temperature, stirred for 5 minutes and mixed evenly to form a dry material, and the dry material is mixed in the following manner: Extrusion mixing, pneumatic mixing or impulse mixing, manual mixing and transfer of the mixed material into a Teflon container approximately 30mm high.

[0020] Add 1ml of deionized water and 2.0ml of industrial alcohol at the bottom of the reactor with a volume of 100ml; put the polytetrafluoroethylene container containing the reaction ...

Embodiment 3

[0021] Example 3: A method of dry powder conversion to synthesize a porous composite framework material. Nickel nitrate is the coordination metal source in the porous composite framework material, and trimesic acid is the ligand of the porous composite framework material. Accurately weigh 0.0061 moles of nitric acid respectively Nickel and 0.0244 moles of trimesic acid, the molar ratio of the coordination metal source and the ligand is 0.5:2, nickel nitrate and trimesic acid are respectively ball milled at room temperature and stirred for 5 minutes to form a dry material. The dry material is mixed in the following manner: Extrusion material mixing, pneumatic mixing or impulsive mixing, using a mechanical device for mixing, the mechanical device is any one of a blender, kneader, mixer, jet mixer or static mixer; then the mixed material Transfer to a Teflon container about 20 mm high.

[0022]Add 1.2ml mineral water and 1.8ml modified ethanol at the bottom of the reaction kettle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com