Absorbing agents, preparation method, application and absorbing materials of magnetic fluorocarbon materials

A technology of fluorinated carbon and wave absorbing agent, which is applied in the field of application and wave absorbing materials, preparation methods, and magnetic fluorinated carbon material wave absorbing agent, which can solve the problem of limiting the application of fluorinated carbon nanotubes, unfavorable large-scale industrial production, carbon Nanotube structure damage and other problems, to achieve excellent impedance matching performance, high absorbing strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In the first aspect, in at least one embodiment, a method for preparing a magnetic fluorinated carbon material wave absorbing agent is provided, comprising the following steps:

[0051] Firstly, Fe3O4 nanoparticles were supported on carbon materials to prepare Fe 3 o 4 @Carbon material composite material, and then treat the Fe at a temperature of 0-30°C 3 o 4 @Carbon material composite material is fluorinated to obtain a magnetic fluorinated carbon material absorber.

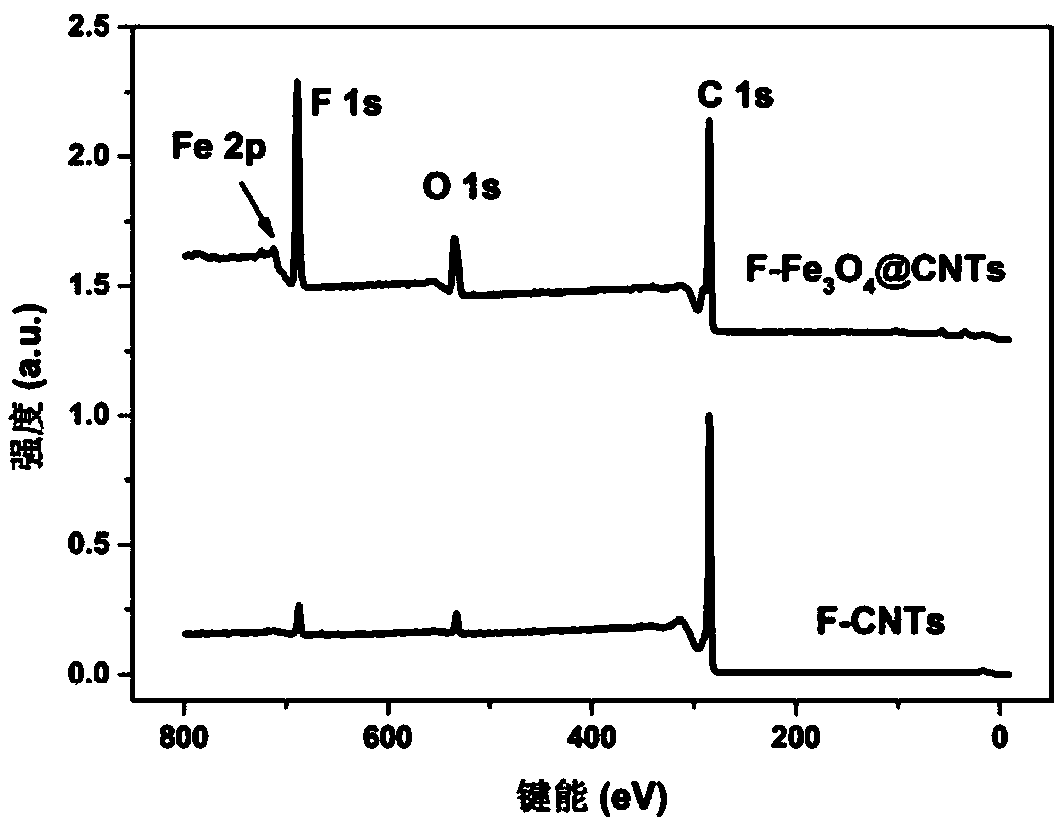

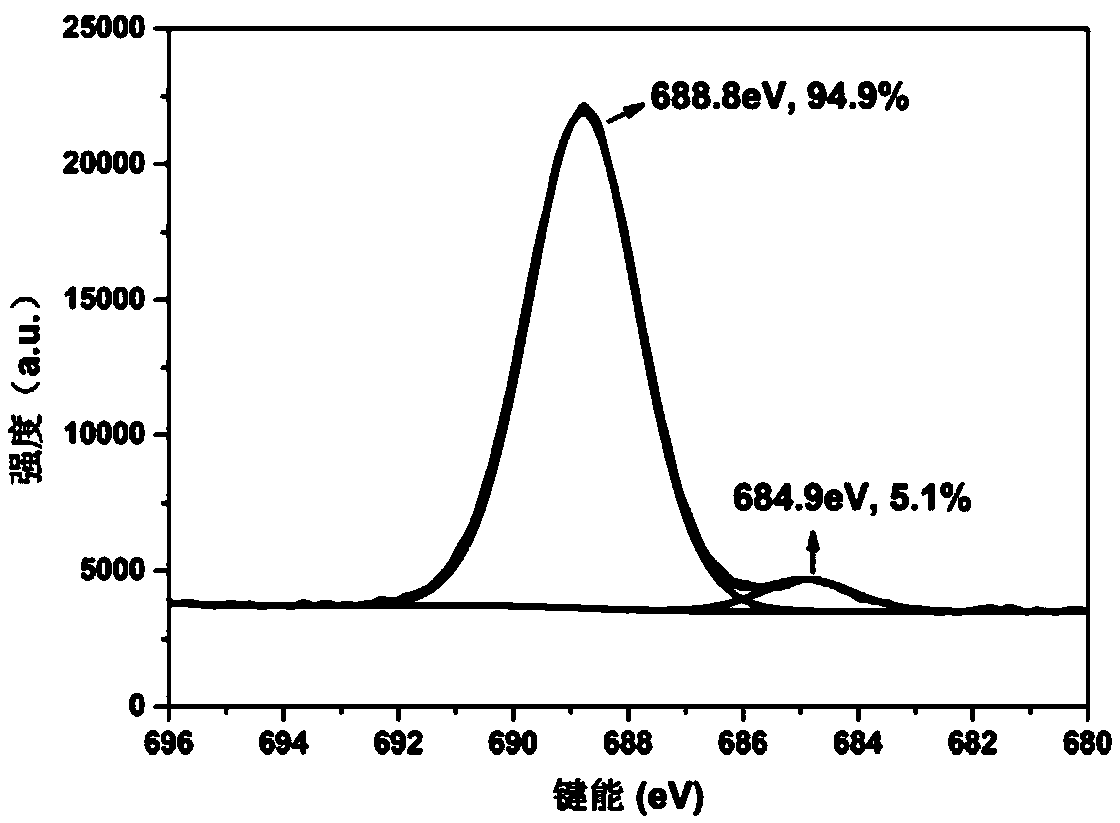

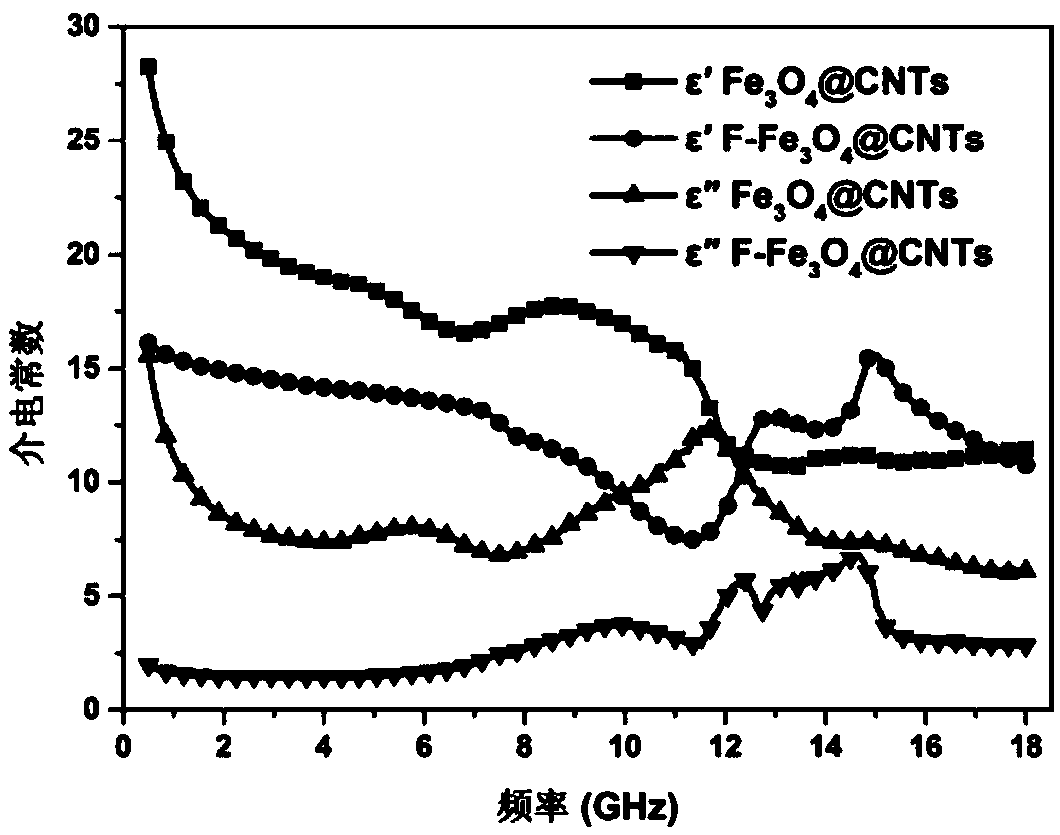

[0052] In the preparation method of the present invention, first ferric oxide nanoparticles are loaded on carbon materials to prepare Fe 3 o 4 @Carbon material composite material, then Fe 3 o 4 @Carbon material composite material is placed in a fluorination reactor at 0-30°C (room temperature) for direct fluorination treatment. On the one hand, the introduction of ferroferric oxide can increase the magnetic properties of carbon nanotubes; on the other hand, ferroferric oxide can increase the fluori...

Embodiment 1

[0087] A preparation method of a magnetic fluorinated carbon material wave absorbing agent, comprising the following steps:

[0088] (a) 400mgFeCl 3 ·6H 2 O was dissolved in 40ml of ethylene glycol, 100mg of carbon nanotubes were added and fully dispersed in an ultrasonic instrument; at the same time, 700mg of sodium acetate was dissolved in 40ml of ethylene glycol to prepare a sodium acetate / ethylene glycol solution;

[0089] (b) Under the protection of nitrogen, the above sodium acetate / ethylene glycol solution was added dropwise to the carbon nanotube-FeCl 3 / Ethylene glycol dispersion, keep stirring for 30 minutes until the liquid is fully mixed;

[0090] (c) Move the above mixed solution into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and keep it at 180°C for 5h;

[0091] (d) Carry out solid-liquid separation to the above-mentioned mixed solution, obtain Fe after washing, drying and grinding 3 o 4 @CNTs nanocomposites;

[0092] (e) 50mg of the abo...

Embodiment 2

[0095] A preparation method of a magnetic fluorinated carbon material wave absorbing agent, comprising the following steps:

[0096] (a) 450mgFeCl 3 ·6H 2 O was dissolved in 40ml of ethylene glycol, 100mg of carbon nanotubes were added and fully dispersed in an ultrasonic instrument; at the same time, 800mg of sodium acetate was dissolved in 40ml of ethylene glycol to prepare a sodium acetate / ethylene glycol solution;

[0097] (b) Under the protection of nitrogen, the above sodium acetate / ethylene glycol solution was added dropwise to the carbon nanotube-FeCl 3 / Ethylene glycol dispersion, keep stirring for 50 minutes until the liquid is fully mixed;

[0098] (c) Transfer the above mixed solution into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and keep it at 190°C for 7h;

[0099] (d) Carry out solid-liquid separation to the above-mentioned mixed solution, obtain Fe after washing, drying and grinding 3 o 4 @CNTs nanocomposites;

[0100] (e) 50mg of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic moment | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com