Hot melt adhesive membrane for reaction type wall cloth and preparation method thereof

A hot melt adhesive film, reactive technology, used in adhesives, films/sheets without carriers, non-polymer adhesive additives, etc. and other problems, to achieve the effect of fast bonding, lasting and stable bonding, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

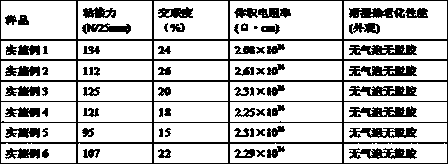

Examples

Embodiment 1

[0035] 30 parts by weight of maleic anhydride grafted ethylene-vinyl acetate copolymer with a graft rate of 1.1wt%, 40 parts of ethylene-vinyl acetate copolymer with a VA content of 33wt% and a melting peak temperature of 70°C 30 parts of ethylene-acrylic acid copolymer with AA content of 15wt% and melting peak temperature of 90°C, 1.1 parts of tert-butylperoxy-3,5,5-trimethylhexyl ester, 0.5 parts of tetraallyloxy Ethane, 0.8 parts of maleic anhydride with a purity of 99.5% and a melting point of 53°C, and 0.8 parts of dioctadecylpentaerythritol bisphosphite were put into a high-speed mixer for mixing, and extruded at 95°C with an extruder to produce After drying, put the hot-melt rubber granules into the casting machine, melt and plasticize at 98°C, and make a hot-melt adhesive with a film thickness of 0.2mm through the processes of extrusion, stretching, traction, and winding. membrane.

Embodiment 2

[0037] 40 parts by weight of maleic anhydride grafted ethylene-vinyl acetate copolymer with a graft rate of 1.5wt%, 40 parts of ethylene-vinyl acetate copolymer with a VA content of 33wt% and a melting peak temperature of 70°C 20 parts of ethylene-acrylic acid copolymer with AA content of 15wt% and peak melting temperature of 90°C, 0.9 parts of 1,1-di-tert-butylperoxycyclohexane, 0.8 parts of vinyltrimethoxyethoxysilane , 0.4 parts of maleic anhydride with a purity of 99.5% and a melting point of 53°C, 0.2 parts of 3,5-di-tert-butyl-4-hydroxybenzyl diethyl phosphonate, put them into a high-speed mixer for mixing, and extruded The extruder is extruded and granulated at 97°C. After drying, the hot-melt rubber granules are put into the casting machine, melted and plasticized at 101°C, and the film is obtained through the processes of extrusion, stretching, traction, and winding. Hot melt adhesive film with a thickness of 0.2mm.

Embodiment 3

[0039] 20 parts by weight of maleic anhydride grafted ethylene-vinyl acetate copolymer with a graft rate of 2.2wt%, 50 parts of ethylene-vinyl acetate copolymer with a VA content of 33wt% and a melting peak temperature of 70°C 30 parts of ethylene-acrylic acid copolymer with AA content of 15wt% and melting peak temperature of 90°C, 0.6 parts of 1,1-di-tert-butylperoxycyclohexane, 1.2 parts of diallyl maleate, 0.7 Parts of maleic anhydride with a purity of 99.5% and a melting point of 53°C, 0.7 parts of 3,5-di-tert-butyl-4-hydroxybenzyl diethylphosphonate, put into a high-speed mixer for mixing, and use an extruder Extrude and granulate at 99°C. After drying, put the hot-melt rubber granules into the casting machine, melt and plasticize at 105°C, and make a film with a thickness of 0.2mm hot melt adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com