A kind of hydrocarbon polymer copper clad laminate composition

A hydrocarbon polymer, copper clad laminate technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of difficult processing, low peel strength, decreased dielectric properties, etc., to improve bending resistance. strength, increasing peel strength, reducing the effect of coefficient of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

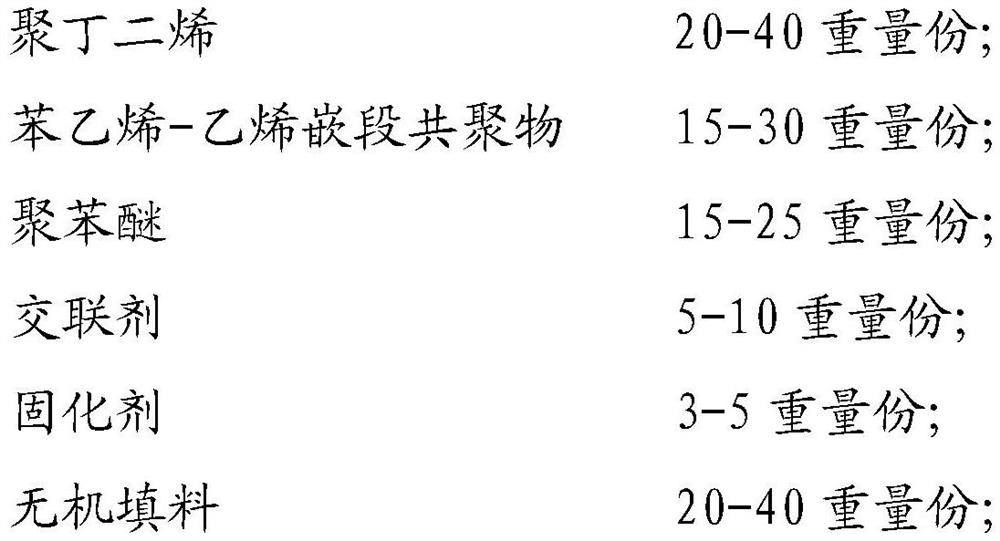

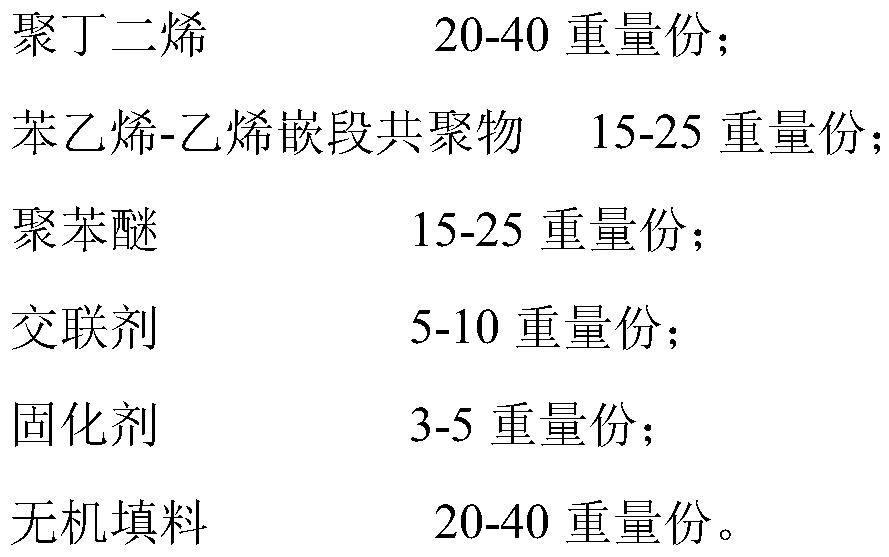

Method used

Image

Examples

Embodiment 1

[0023] A1 polybutadiene;

[0024] A2 styrene-ethylene block copolymer;

[0025] A3-1 polyphenylene ether (average molecular weight 60000);

[0026] A3-2 polyphenylene ether (average molecular weight 90000);

[0027] A3-3 polyphenylene ether (average molecular weight 40000);

[0028] A4-1 EPDM rubber;

[0029] A4-2 triallyl isourea cyanate (TAIC);

[0030] B1 dicumyl peroxide;

[0031] B2 2,3-dimethyl-2,3-diphenylbutane;

[0032] C1 silica;

[0033] C2 alumina.

[0034] The laminate base material of the present invention is made by adding xylene to the above resin composition and heating and mixing at 60°C to 75°C for 3-5 hours, then using xylene to adjust a suitable viscosity to obtain glue, 1080 glass fiber cloth impregnated with glue, and dried Dry remove the solvent to obtain a prepreg, the thickness of the prepreg on both sides is 0.5 ounces (18um thick) copper foil, through a hot press, control the temperature of the material at 220-260 ° C, and keep it warm for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com