Concrete, air-entraining agent and preparation method for application in alpine and high-altitude regions

A concrete and high-altitude technology, used in concrete, concrete air-entraining agent, air-entraining agent and preparation fields in high-cold and high-altitude areas, can solve the problem that the air-entraining agent cannot be used in high-cold and high-altitude areas, and reduce freeze-thaw damage. effect, improve impermeability, reduce capillary action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example provides a kind of concrete air-entraining agent used in high-cold and high-altitude areas, which is made of the following raw materials in parts by weight: 93% of triterpene saponin solution, 2.2% of modified polybutadiene resin, Modified polyacrylamide is 0.85%, sodium carbonate is 3.95%.

[0040] The number average molecular weight of the modified polybutadiene resin is 1000-30000; the number average molecular weight of the modified polyacrylamide is 10000-40000.

[0041] The preparation method of the concrete air-entraining agent applied to the alpine and high-altitude regions of the present embodiment comprises the following steps:

[0042] Step 1, prepare the preparation of triterpene saponin solution:

[0043] Weigh the acacia, remove surface dirt with a cleaning solution, expose the cleaned acacia to the sun for 3 to 5 days, and pulverize the dried acacia with a pulverizer to obtain acacia powder; mix the acacia powder with ethanol and acetone The...

Embodiment 2

[0057] This embodiment provides a kind of concrete air-entraining agent used in high-cold and high-altitude areas, which is made of the following raw materials in parts by weight: triterpene saponin solution is 92% to 95%, and modified polybutadiene resin is 1.8%-2.8%, modified polyacrylamide 0.7%-0.95%, sodium carbonate 2.5%-4.5%, and the sum of the parts by weight of raw materials is 100%.

[0058] This example provides a kind of concrete air-entraining agent used in high-cold and high-altitude areas, which is made of the following raw materials in parts by weight: 92% of triterpene saponin solution, 2.8% of modified polybutadiene resin, Modified polyacrylamide is 0.95%, sodium carbonate is 4.25%.

[0059] The modified polybutadiene resin is the same as in Example 1.

[0060] Modified polyacrylamide is the same as Example 1.

[0061] The preparation method of this embodiment is basically the same as that of Example 1.

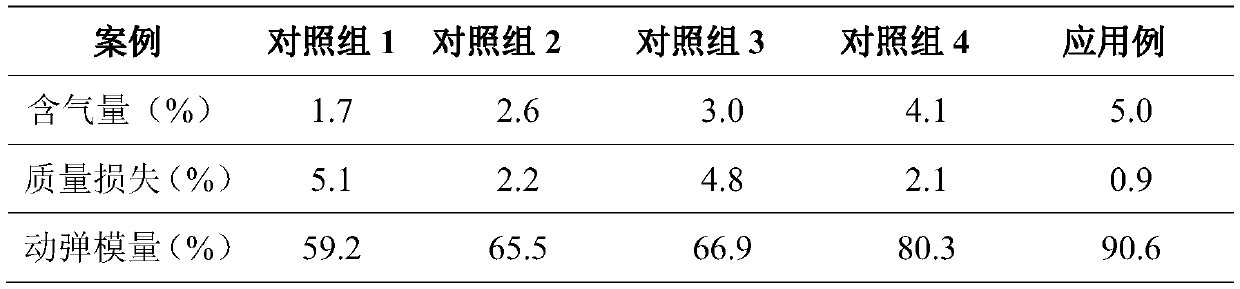

[0062] The application effect of the concrete air-en...

Embodiment 3

[0064] This example provides a kind of concrete air-entraining agent used in high-cold and high-altitude areas, which is made of the following raw materials in parts by weight: 95% of triterpene saponin solution, 1.8% of modified polybutadiene resin, Modified polyacrylamide is 0.7%, sodium carbonate is 2.5%.

[0065] The modified polybutadiene resin is the same as in Example 1.

[0066] Modified polyacrylamide is the same as Example 1.

[0067] The preparation method of this embodiment is basically the same as that of Example 1.

[0068] The application effect of the concrete air-entraining agent prepared in this embodiment is basically the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com