A kind of preparation method of tungsten oxide electrochromic electrode

An electrochromic and tungsten oxide technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of difficult large-scale preparation, complex and expensive equipment, difficult operation, etc., and achieve simple process, shortened discoloration time, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Dissolve 2g of tungsten hexachloride in 25mL of absolute ethanol, stir and dissolve at 30°C for 20min to obtain a 0.2mol / L blue precursor solution.

[0030] (2) Heat the FTO glass substrate to 50°C, press 1mL / cm 2 The amount of the precursor solution prepared in step (1) is evenly sprayed on the conductive surface of FTO glass under the air pressure of 0.2MPa; it is irradiated with an ultraviolet lamp with a wavelength of 400nm and a power of 5W for 2min to obtain the surface-attached tungsten oxide electrochromic Thin film FTO electrodes.

[0031] (3) Place the FTO conductive glass with the tungsten oxide electrochromic film attached to the surface prepared in step (2) in a vacuum oven and dry at 60° C. for 4 hours to obtain a tungsten oxide electrochromic electrode.

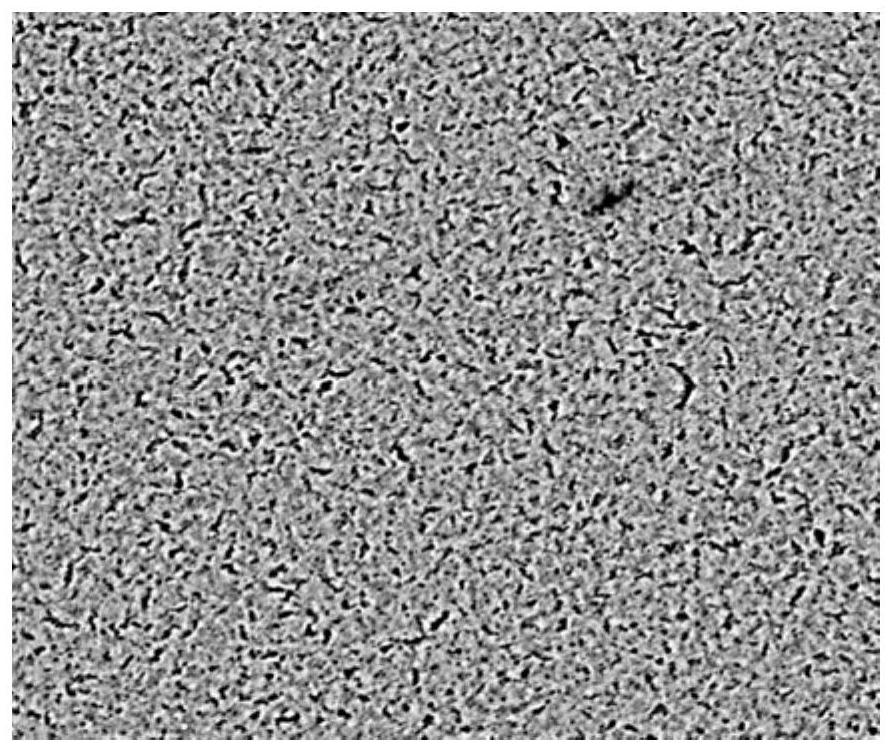

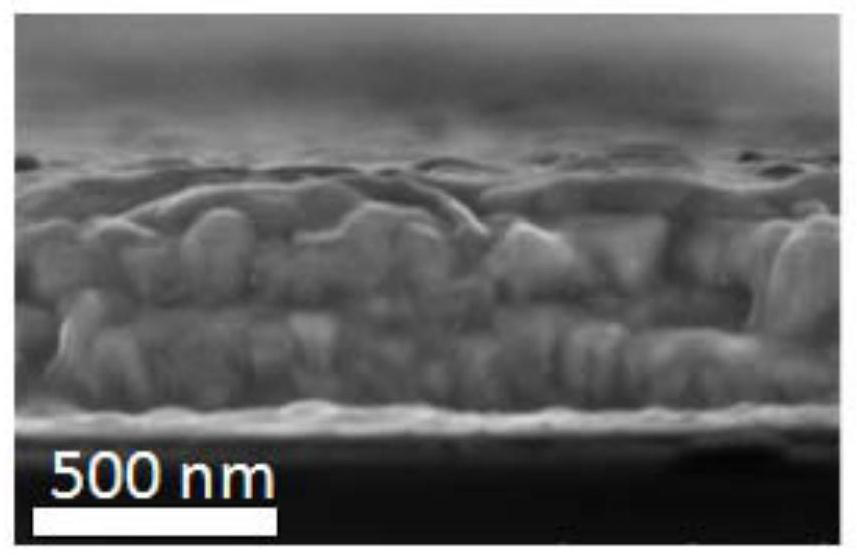

[0032] The scanning electron microscope picture of the tungsten oxide electrochromic electrode surface that the present embodiment makes is as figure 2 As shown, it shows that the tungsten oxide e...

Embodiment 2

[0036] (1) Dissolve 4g of tungsten hexachloride in 10mL of absolute ethanol, stir and dissolve at 50°C for 100min to obtain a 1mol / L blue precursor solution.

[0037] (2) Heat the FTO glass substrate to 100°C, press 5mL / cm 2 Spray the precursor solution prepared in step (1) evenly on the conductive surface of FTO glass under 0.5MPa pressure; use a UV lamp with a wavelength of 365nm and a power of 10W to irradiate for 30min to obtain a tungsten oxide electrochromic film attached to the surface The FTO electrode.

[0038] (3) Place the FTO conductive glass with the tungsten oxide electrochromic film on the surface prepared in step (2) and dry it in a vacuum oven at 100° C. for 10 hours to obtain a tungsten oxide electrochromic electrode.

[0039] The light modulation range of the tungsten oxide electrochromic electrode prepared in this embodiment is as follows: Figure 5 As shown, the results show that at λ=632.8nm, the light modulation range of the FTO electrode is 30.71%. B...

Embodiment 3

[0041] (1) Dissolve 16g of tungsten hexachloride in 20mL of absolute ethanol, stir and dissolve at 80°C for 300min to obtain a 2mol / L blue precursor solution.

[0042] (2) Heat the FTO glass substrate to 150°C, press 10mL / cm 2 The amount of the precursor solution prepared in the step (1) is evenly sprayed on the FTO glass conductive surface under 1MPa pressure; using a wavelength of 345nm and a power of 30W UV lamp for 60min irradiation, the surface is obtained with tungsten oxide electrochromic film. FTO electrodes.

[0043] (3) Place the FTO conductive glass with the tungsten oxide electrochromic film on the surface prepared in step (2) and dry it in a vacuum oven at 120° C. for 12 hours to obtain a tungsten oxide electrochromic electrode.

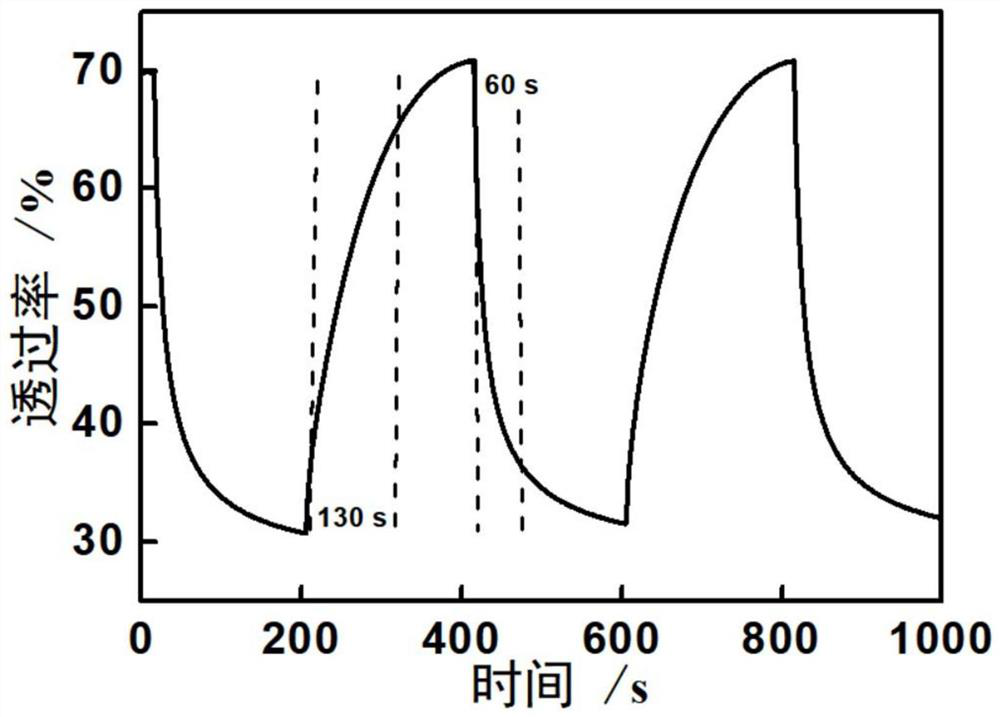

[0044] The time response curve of the tungsten oxide electrochromic electrode prepared in this embodiment is as follows figure 1 As shown, it can be seen that the discoloration speed of the prepared tungsten oxide electrode is relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com