Preparation method of stain-resisting fiber for weaving outdoor hanging chairs

A hanging chair, stain-resistant technology, applied in fiber processing, cellulose/protein conjugated rayon, textiles and papermaking, etc., can solve problems such as affecting people's use, easy to be contaminated with dust, etc., and achieve excellent aging resistance, improved Anti-fouling performance, effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

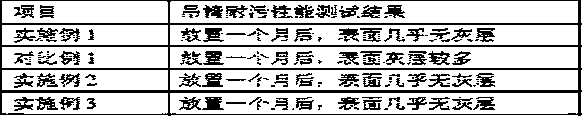

Examples

Embodiment 1

[0015] A preparation method of stain-resistant fibers for weaving outdoor hanging chairs, comprising the following steps:

[0016] (1) Put the sisal fiber into the benzoyl peroxide solution with a concentration of 0.15g / ml, soak it for 2 hours, then take out the sisal fiber, completely immerse it in boiling water five times its weight, and use a small After heating for 10 minutes, add 10% by weight of the mixed grafting monomer to boiling water, and after grafting for 3 hours, a modified sisal fiber is obtained, wherein the mixed grafting monomer is made of the following components by weight: : 6 parts of dodecafluoroheptyl acrylate, 14 parts of 2,2,2-trifluoroethyl acrylate, 36 parts of methyl methacrylate;

[0017] (2) Add the polymer resin particles to the mill, after they are completely melted, add the modified sisal fiber with 25% weight of the polymer resin particles to it, and mix the materials for 5 minutes to obtain the modified sisal fiber Filled polymer composite m...

Embodiment 2

[0022] A preparation method of stain-resistant fibers for weaving outdoor hanging chairs, comprising the following steps:

[0023] (1) Put the sisal fiber into the benzoyl peroxide solution with a concentration of 0.17g / ml, soak it for 2.5 hours, then take out the sisal fiber, completely immerse it in boiling water 5.5 times its weight, and use a small After heating for 13 minutes, add 13% of its weight mixed grafting monomer to boiling water, and after grafting reaction for 3.5 hours, a modified sisal fiber is obtained, wherein the mixed grafting monomer is made of the following components by weight : 8 parts of dodecafluoroheptyl acrylate, 16 parts of 2,2,2-trifluoroethyl acrylate, 38 parts of methyl methacrylate;

[0024] (2) Add the polymer resin particles to the mill, and after they are completely melted, add modified sisal fibers with a weight of 28% of the polymer resin particles, and mix them for 5 minutes to obtain modified sisal fibers Filled polymer composite mater...

Embodiment 3

[0029] A preparation method of stain-resistant fibers for weaving outdoor hanging chairs, comprising the following steps:

[0030] (1) Put the sisal fiber into the benzoyl peroxide solution with a concentration of 0.2g / ml, soak it for 3 hours, then take out the sisal fiber, completely immerse it in boiling water six times its weight, and use a small After heating for 15 minutes, add 15% of its weight mixed grafting monomer into boiling water, and after grafting reaction for 4 hours, a modified sisal fiber is obtained, wherein the mixed grafting monomer is made of the following components by weight: : 10 parts of dodecafluoroheptyl acrylate, 20 parts of 2,2,2-trifluoroethyl acrylate, 40 parts of methyl methacrylate;

[0031] (2) Add the polymer resin particles to the mill, and after they are completely melted, add the modified sisal fiber with 30% weight of the polymer resin particles to it, turn over and blend for 6 minutes, and obtain the modified sisal fiber Filled polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com