Graphene modified water-based epoxy coating reinforcing steel bar as well as preparation method thereof

A graphene-modified, water-based epoxy technology, applied in the field of steel anti-corrosion, can solve the problems of easy damage of epoxy resin powder, weak corrosion resistance, insufficient bonding strength, etc., to avoid excessive zinc powder content and good anti-corrosion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Prepare 100g of paint

[0104] Graphene dispersion: prepare 100ml of 10mg / ml polyvinylpyrrolidone solution, add 0.2g of graphene and 0.2g of water-based coupling agent, ultrasonically disperse in an ice-water bath for 12 hours, after standing for 24 hours, centrifuge at high speed for 60min, and take the supernatant liquid to obtain a graphene dispersion.

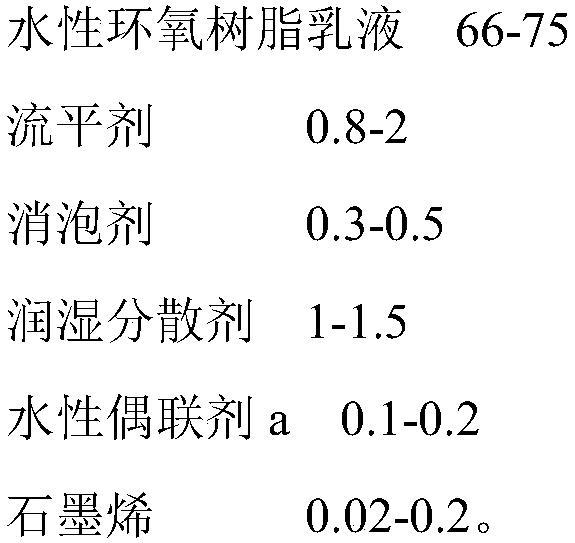

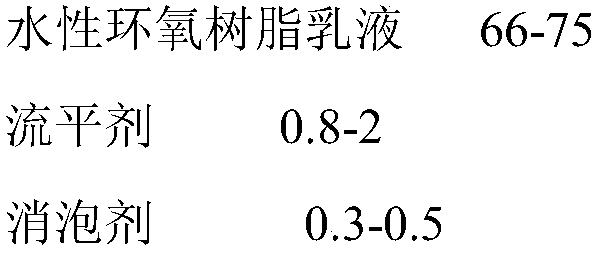

[0105] Add 72.33g of water-based epoxy resin emulsion to 15ml of graphene dispersion to obtain a mixed solution, add 0.50g of defoamer, 1.50g of wetting and dispersing agent, and 1.0g of leveling agent in sequence under high-speed stirring, and stir for 30 minutes at high speed, according to actual needs Add vacuum to evaporate excess water or add appropriate amount of water to dilute to obtain A component.

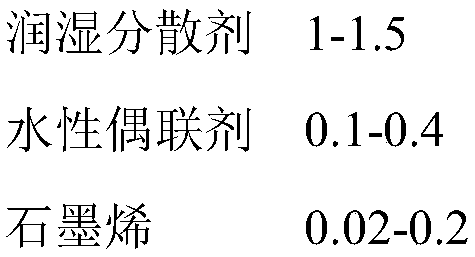

[0106] Under high-speed stirring, add 0.6 anti-sedimentation thixotropic agent and 0.2 g water-based coupling agent in sequence to 23.29 g of modified polyamine curing agent (G-602), and stir at high speed for ...

Embodiment 2

[0110] Prepare 100g of paint

[0111] Graphene dispersion: prepare 100ml of 10mg / ml polyvinylpyrrolidone solution, add 0.2g of graphene and 0.2g of water-based coupling agent, ultrasonically disperse in an ice-water bath for 12 hours, after standing for 24 hours, centrifuge at high speed for 60min, and take the supernatant liquid to obtain a graphene dispersion.

[0112] Add 68.69 g of water-based epoxy resin emulsion to 20ml of graphene dispersion to obtain a mixed solution, add 0.47g of defoamer, 1.42g of wetting and dispersing agent, and 0.95g of leveling agent in sequence under high-speed stirring, stir at high speed for 30min, and add according to actual needs Evaporate excess water in vacuo or add appropriate amount of water to dilute to obtain component A.

[0113] Under high-speed stirring, 0.4 anti-sedimentation thixotropic agent, 0.2 g water-based coupling agent were sequentially added to 22.12 g of modified polyamine curing agent, and stirred at high speed for 30 m...

Embodiment 3

[0117] Prepare 100g of paint, graphene dispersion: prepare 100ml of 10mg / ml polyvinylpyrrolidone solution, add 0.2g of graphene and 0.2g of water-based coupling agent, ultrasonically disperse in an ice-water bath for 12 hours, after standing for 24 hours, centrifuge at high speed for 60min , take the supernatant to obtain a graphene dispersion.

[0118] Add 67.76g of water-based epoxy resin emulsion to 25ml of graphene dispersion to obtain a mixed solution, add 0.47g of defoamer, 1.40g of wetting and dispersing agent, and 0.94g of leveling agent in sequence under high-speed stirring, and stir for 30 minutes at high speed, according to actual needs Add vacuum to evaporate excess water or add appropriate amount of water to dilute to obtain A component.

[0119] Under high-speed stirring, 0.6 anti-sedimentation thixotropic agent, 0.2 g water-based coupling agent were sequentially added to 21.82 g of modified polyamine curing agent, and stirred at high speed for 30 minutes to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com