Automatic tool conveying assembly line

A technology of assembly line and tooling, which is applied in the direction of transportation, packaging, roller table, etc., can solve the problems of transmission stability, motor burnout, damage to tooling, etc., and achieve the effect of improving stability, preventing abnormal friction, and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

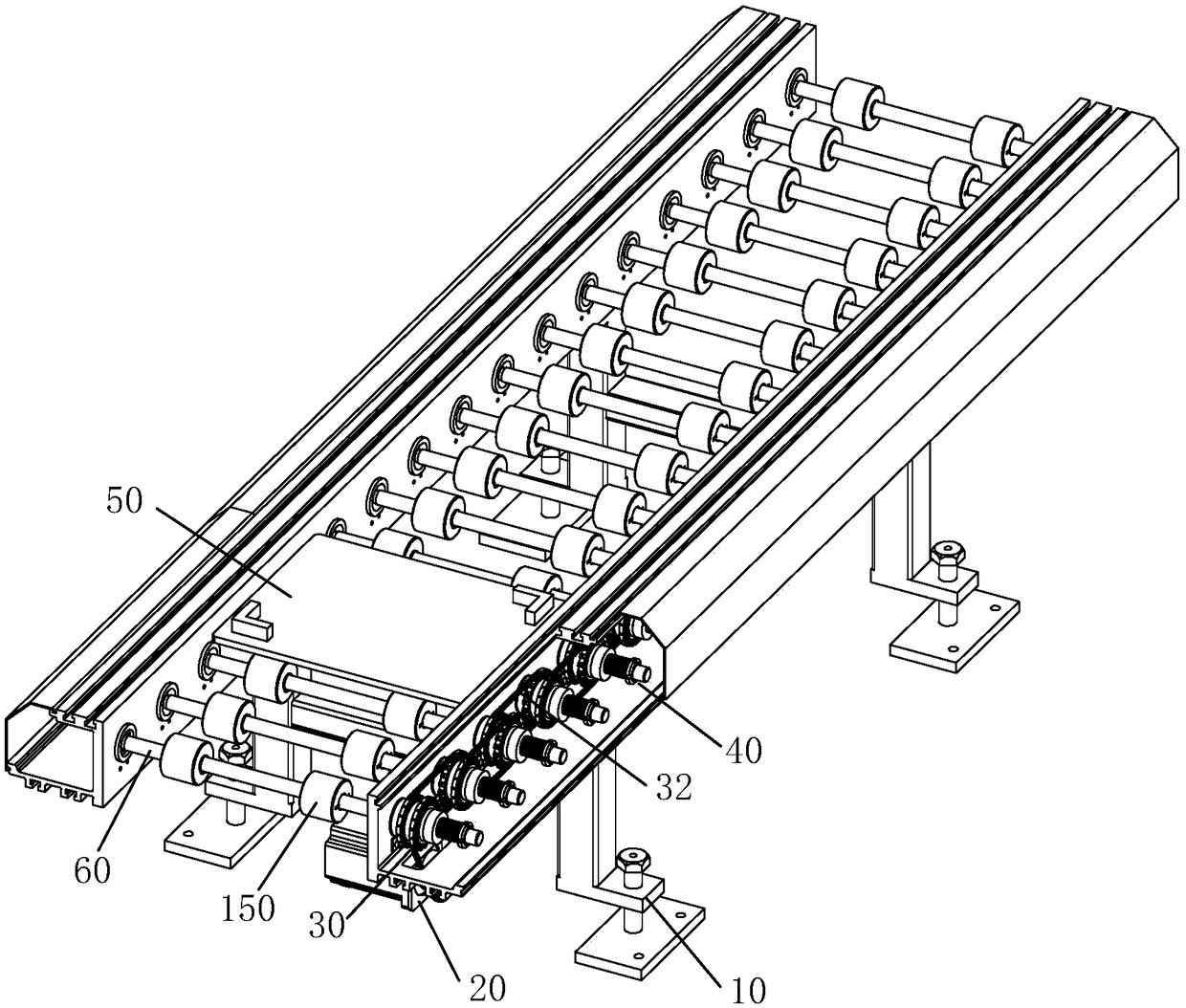

[0043] like figure 1 and figure 2 As shown, an automated tooling conveying assembly line includes an assembly line support 10, a motor power assembly 20, the motor power is transmitted to the transmission shaft assembly 40 through the transmission chain 30, and the adjacent transmission shaft assembly 40 transmits the power of the motor through the cascade chain 32 in sequence, and the transmission The transmission wheel 150 on the shaft assembly 40 drives the tooling 50 through friction to realize automatic forward and backward transportation.

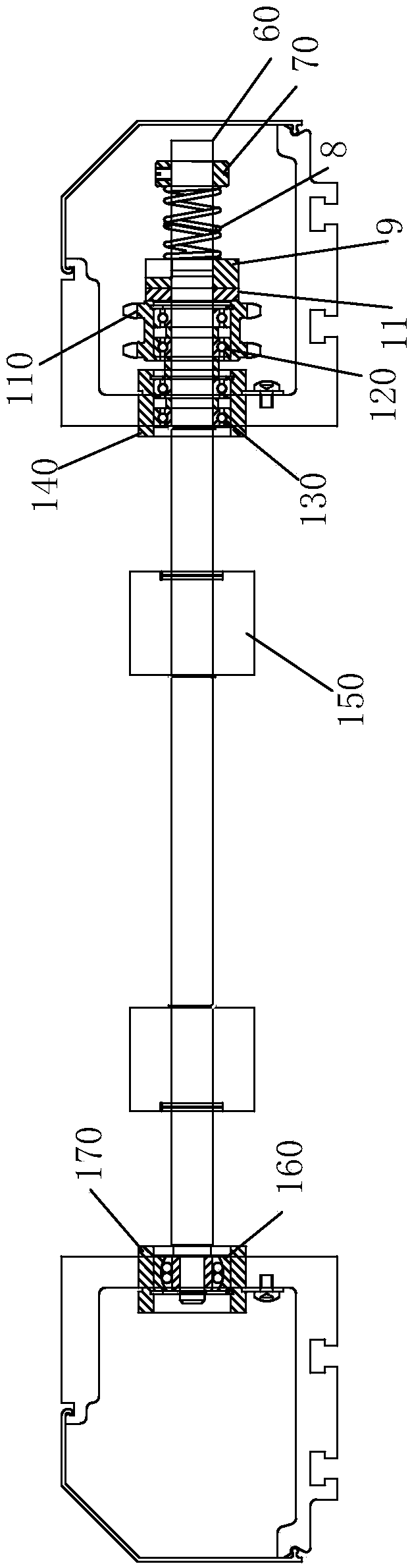

[0044] In this embodiment, the assembly line support 10 is provided with multiple sets of drive shaft assemblies 40 arranged side by side, and each set of drive shaft assemblies includes a drive shaft 60 and a drive wheel 150 disposed on the drive shaft 60 . One end of each transmission shaft 60 is installed and fixed to one side of the assembly line support 10 through the third bearing holder 140, and the third bearing 130 is also ...

Embodiment 2

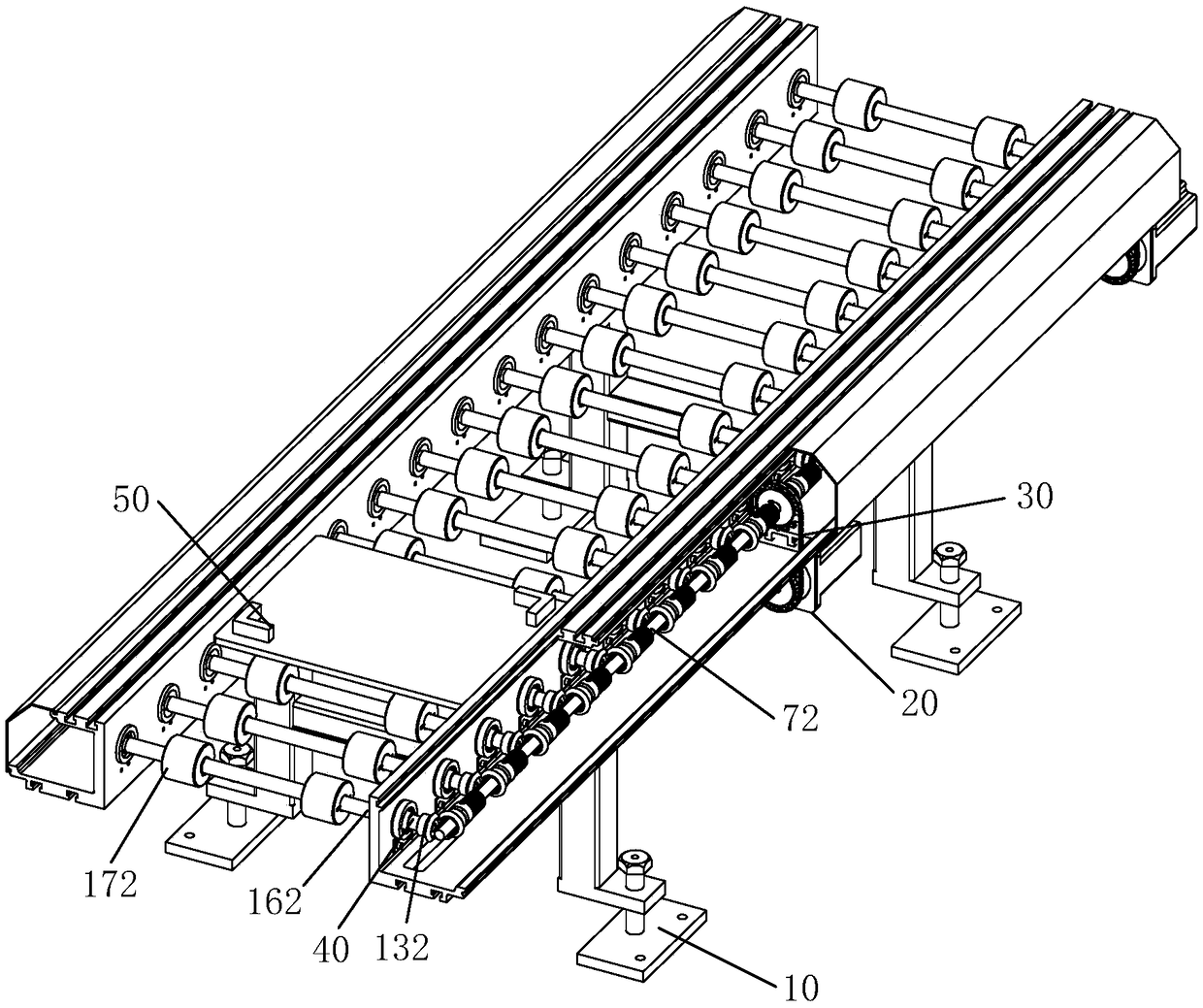

[0050] like image 3 and Figure 4 As shown, an automated tooling conveying assembly line includes an assembly line support 10, a motor power assembly 20, and the motor power is transmitted to the driving shaft 72 through the transmission chain 30. The gear 132 is meshed for transmission.

[0051] Same as the first embodiment, the assembly line support 10 is provided with multiple sets of drive shaft assemblies 40 arranged side by side, and each set of drive shaft assemblies includes a drive shaft 162 and a drive wheel 172 disposed on the drive shaft 162 . One end of each transmission shaft 162 is installed and fixed to one side of the assembly line support 10 by the third bearing holder 142, and the third bearing 152 is also installed in the third bearing holder 142; the other end of the transmission shaft 162 passes through the third bearing The fixing seat 182 is installed and fixed on the other side of the assembly line support 10 , and a third bearing 192 is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com