Manufacturing technique and manufacturing equipment of silicon iron powder for secondary aluminum and diamond flotation

A technology of production process and manufacturing equipment, which is applied in the production process and manufacturing equipment of ferrosilicon powder for diamond flotation, and the field of recycled aluminum. It can solve the problems of high density of ferrosilicon powder, low beneficiation efficiency, and loss of ferrosilicon powder. , to achieve the effect of not easy to settle, convenient to sort and collect, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Production process and manufacturing equipment for the production of 100 mesh ferrosilicon powder

[0036] 1) Pretreatment of raw materials: derusting treatment of scrap steel, crushing ferrosilicon to 7cm, mixing 35 parts of boron mud, 30 parts of spodumene and 30 parts of limestone as a slag accumulator in parts by weight, and drying for later use;

[0037] 2) For smelting, the raw materials are 800 parts by weight of steel scrap, 200 parts of ferrosilicon and 50 parts of slag accumulator are put into electric furnace for smelting, and the smelting temperature of electric furnace is 1500℃;

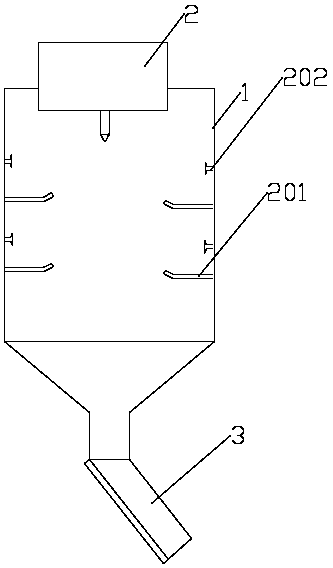

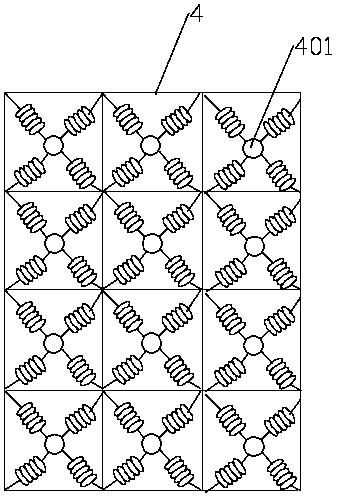

[0038]3) Water atomization. After smelting, the solution enters the vacuum water atomization system for powder preparation. The water spray pressure in the vacuum water atomization system is 300Mpa, the diameter of the water spray orifice is 0.4mm, and the first atomization high-pressure nozzle phase The inclination angle is 30° compared to the horizontal direction; a f...

Embodiment 2

[0043] Embodiment 2: Production process and manufacturing equipment during the production of 200 mesh ferrosilicon powder

[0044] 1) Pretreatment of raw materials: derusting treatment of scrap steel, crushing ferrosilicon to 7cm, mixing 35 parts of boron mud, 30 parts of spodumene and 30 parts of limestone as a slag accumulator in parts by weight, and drying for later use;

[0045] 2) For smelting, 750 parts of steel scrap, 250 parts of ferrosilicon and 60 parts of slag accumulator are put into the electric furnace for smelting, and the smelting temperature of the electric furnace is 1500 ℃;

[0046] 3) Water atomization. After smelting, the solution enters the vacuum water atomization system for powder preparation. The water spray pressure in the vacuum water atomization system is 600Mpa, the diameter of the water spray orifice is 0.4mm, and the first atomization high-pressure nozzle phase The inclination angle is 40° compared to the horizontal direction; a filter device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com