A processing tool and processing method for honeycomb material with large cutting angle and low damage

A technology of honeycomb material and processing method, which is applied to cutting tools, manufacturing tools, metal processing equipment and other directions of sawing machine devices, can solve the problems of low damage processing of honeycomb materials, etc., to reduce surface burrs, reduce surface burrs, and reduce cutting temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

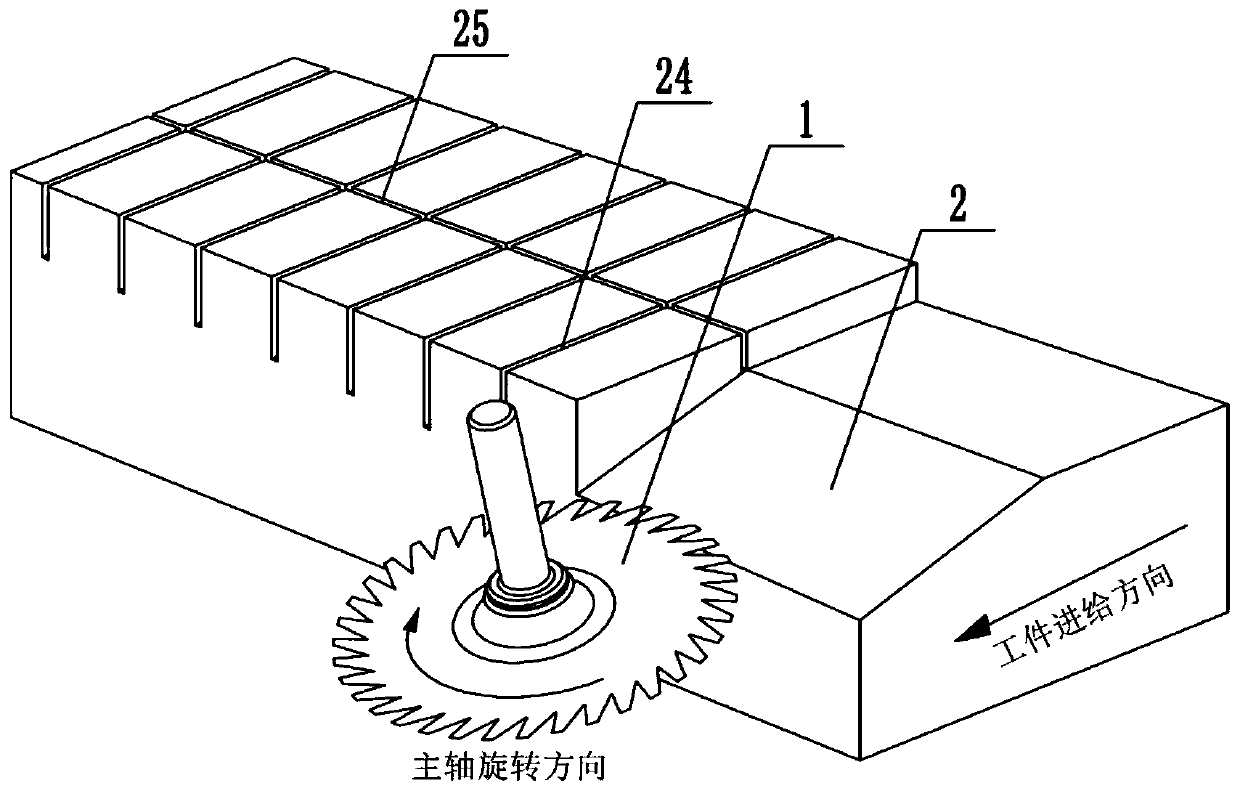

[0052] Such as figure 1 As shown, this is the processing process of the large-cut angle and low-damage processing method when the honeycomb material is processed on a large-area plane. Since the tool 1 is not integrated with a crushing blade, the machining allowance area of the workpiece 2 must be provided with longitudinal grooves 24 and transverse grooves 25 to achieve chip breaking during cutting, and the groove distance is selected according to corresponding calculations.

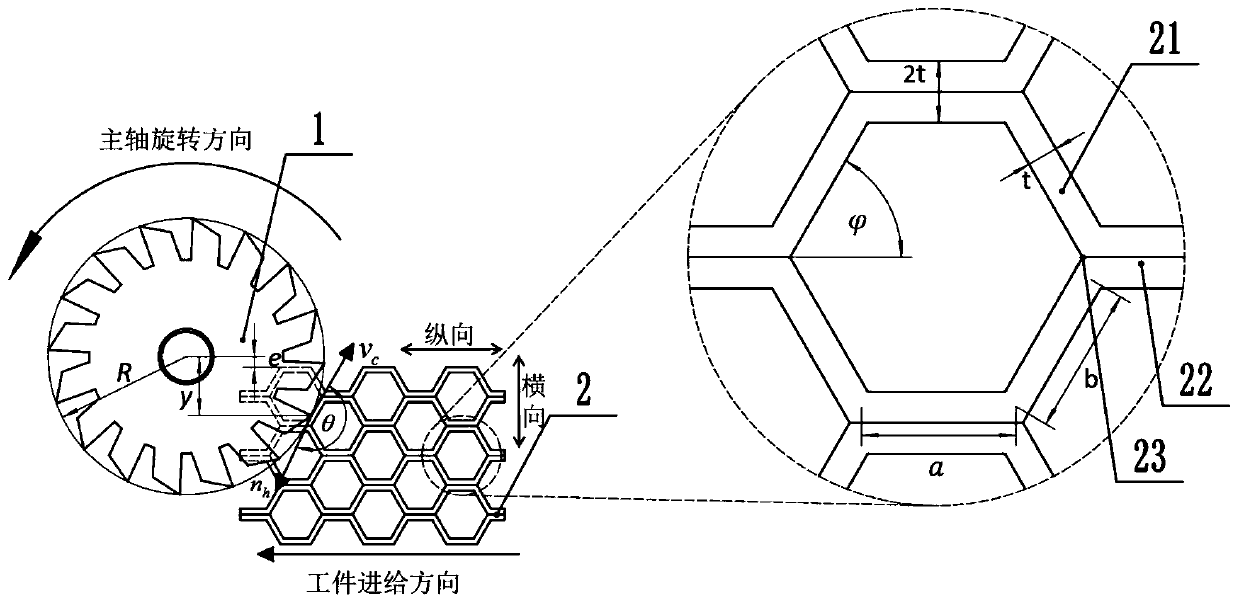

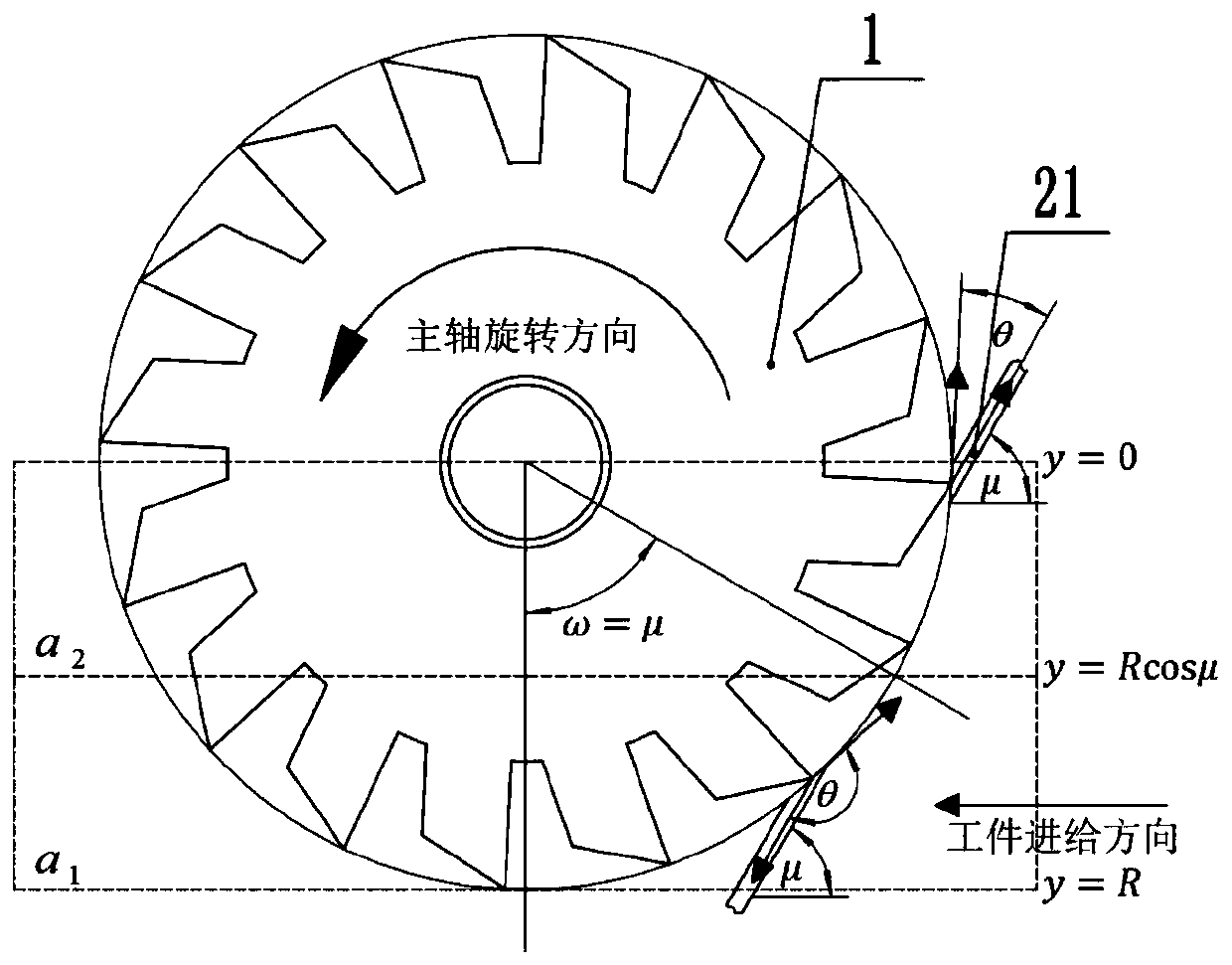

[0053] Such as figure 2 As shown, the cutting angle θ has a significant effect on the processing quality in the processing of honeycomb materials. The test results show that when the cutting angle is 90°≤θh and cutting speed v c The included angle, while the hole wall vector n h Refers to the vector pointing from the cut-off end to the unprocessed area along the direction of the cell wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com