A kind of aluminum base tube for photosensitive drum with bright and smooth surface and its manufacturing method

A manufacturing method and photosensitive drum technology, applied in wire drawing dies, metal extrusion dies, etc., can solve the problems of high surface roughness, surface brightness and smoothness of aluminum tubes, etc. The use cycle and life, and the effect of dimensional accuracy stably reaching the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0052] Chemical composition of raw materials, Mn: 1.427%, Si: 0.052%, Fe: 0.412%, Cu: 0.180%, Mg: 0.008%.

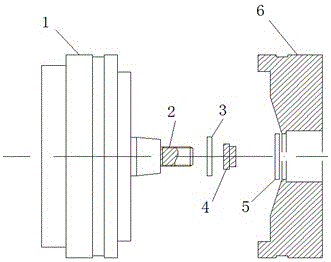

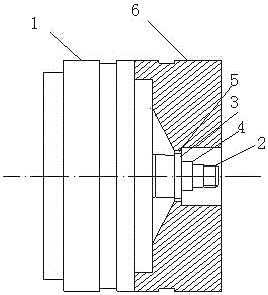

[0053] Extrusion process and extrusion billet size: The size of the extruded aluminum tube is 38mm in outer diameter, 1.3mm in wall thickness and 33mm in outer diameter, 1.3mm in wall thickness.

[0054] Materials for extrusion dies: Traditional H13 steel and YG8N tungsten alloy steel are used respectively.

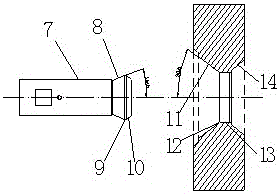

[0055] Drawing die improvement: The traditional arc angle and the improved tapered angle are used respectively.

[0056] The dimensions of the conical die are:

[0057] Outer mold: deformation cone angle 60°, sizing working belt length 10mm;

[0058] Inner mold: Deformation cone angle 20°, sizing working belt length 2mm.

[0059] Lubricating oil viscosity for drawing: 800cst and 200cst were used respectively.

[0060] After the extrusion and drawing process, samples were taken for roughness and surface defect detection and analysis. The analysis results are show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com