Preparation method and application of loaded nano gold catalyst

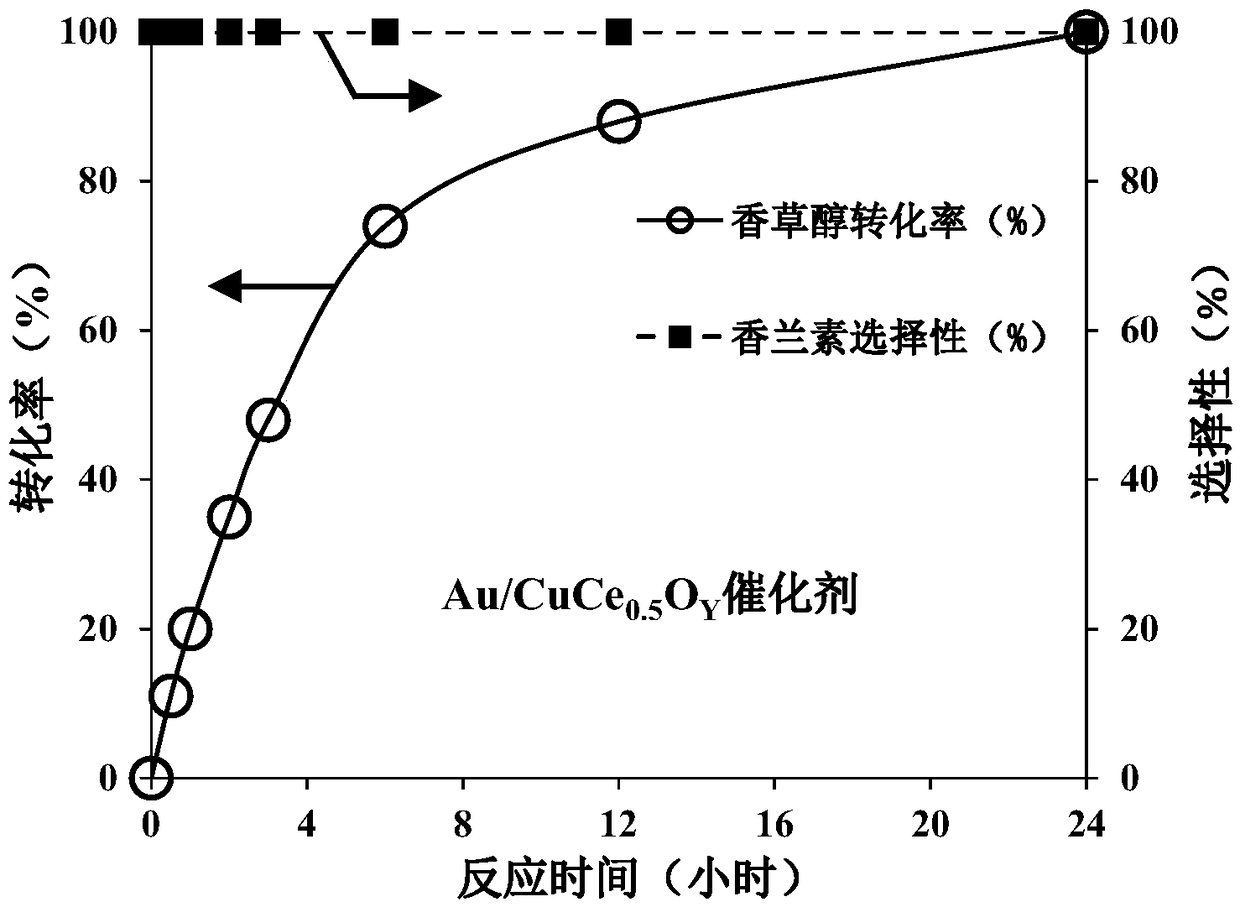

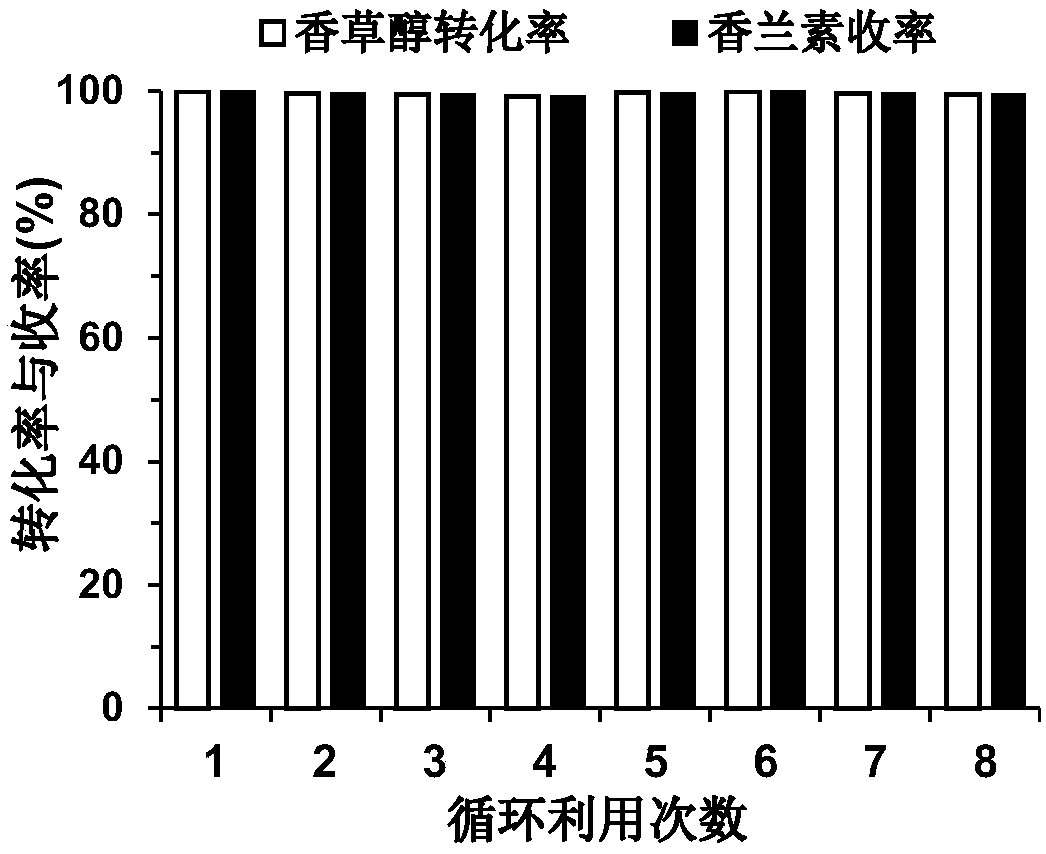

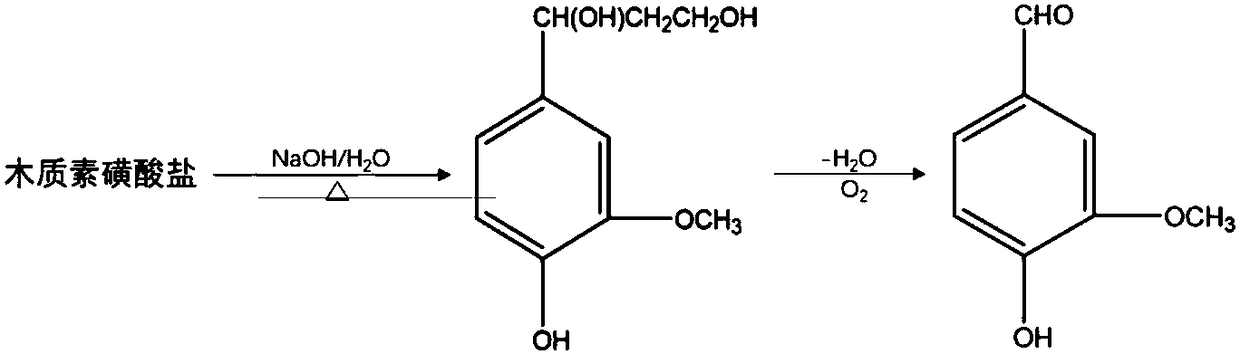

A catalyst and nano-gold technology, applied in the field of vanillin synthesis, can solve the problems of complex catalyst synthesis process, loss of metal palladium components, harsh reaction conditions, etc., to improve the utilization rate of raw materials, the yield of target products, and the selection of Sex and reaction conditions are more effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention discloses a preparation method of a supported nano-gold catalyst, comprising the following steps:

[0053] Step 1. Preparation of carrier Cu-Ce-O Y :

[0054] Step 1.1, the CuN 2 o 6 ·3H 2 O and CeN 3 o 9 ·6H 2 O was dissolved in methanol to prepare solution Ⅰ; among them, CuN 2 o 6 ·3H 2 O and CeN 3 o 9 ·6H 2 The molar ratio of O is 1:0.2-2:3; CuN 2 o 6 ·3H 2 The molar volume ratio (mmol / ml) of O to methanol is 16:155-26.7:100;

[0055] Step 1.2, under magnetic stirring (speed: 400-700rpm), add triethylamine drop by drop with a dropping funnel until the solution pH=9, and then age in an oil bath at a constant temperature of 60-80°C for 12-24h;

[0056] Step 1.3. Pour the aged suspension into a sand core funnel for suction filtration, fully wash with deionized water until neutral, and then wash with absolute ethanol; after washing, the obtained filter cake is dried at 100-120°C 10-14h, after grinding, calcined at 290-610°C for 4-6h under a...

Embodiment 1

[0063] A preparation method of supported nano gold catalyst, comprising the following steps:

[0064] Step 1, preparation of carrier Cu 1 Ce 0.5 o Y :

[0065] Step 1.1, weigh 6.43g (26.7mmol) CuN 2 o 6 ·3H 2 O and 5.77g (13.3mmol) CeN 3 o 9 ·6H 2 O was dissolved in 150ml methanol to prepare solution Ⅰ;

[0066] Step 1.2. Under magnetic stirring (speed: 600rpm), triethylamine was added dropwise with a dropping funnel until the solution pH=9, and then aged in an oil bath at a constant temperature of 65°C for 18 hours;

[0067] Step 1.3, pour the aged suspension into a sand core funnel for suction filtration, fully wash with deionized water until neutral, and then wash with absolute ethanol; after washing, the obtained filter cake is dried at 110°C for 12h, After grinding, it was calcined at 500°C for 4h in the air atmosphere; the carrier Cu 1 Ce 0.5 o Y , stored for use;

[0068] Step 2, prepare catalyst:

[0069] Step 2.1, prepare 0.005g / ml aqueous chloroauric a...

Embodiment 2

[0074] A preparation method of supported nano gold catalyst, comprising the following steps:

[0075] Step 1, preparation of carrier Cu 1 Ce 0.2 o Y :

[0076] Step 1.1, weigh 8.05g (33.3mmol) CuN 2 o 6 ·3H 2 O and 2.91g (6.7mmol) CeN 3 o 9 ·6H 2 O was dissolved in 130ml methanol to prepare solution Ⅰ;

[0077] Step 1.2. Under magnetic stirring (speed: 500rpm), triethylamine was added dropwise with a dropping funnel until the solution pH = 9, and then aged in an oil bath at a constant temperature of 60°C for 15 hours;

[0078] Step 1.3, pour the aged suspension into a sand core funnel for suction filtration, fully wash with deionized water until neutral, and then wash with absolute ethanol; after washing, the obtained filter cake is dried at 100°C for 10 hours, After grinding, it was calcined at 500°C for 4h in the air atmosphere; the carrier Cu 1 Ce 0.2 o Y , stored for use;

[0079] Step 2, prepare catalyst:

[0080] Step 2.1, preparing 0.005g / ml aqueous chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com