Myofibrillar protein/xanthan gum composite emulsion rich in functional factors

A technology of myofibrillar protein and functional factor, applied in the field of food processing, can solve the problems of layering behavior, easy aggregation and flocculation, etc., and achieve the effects of low cost, short production cycle and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

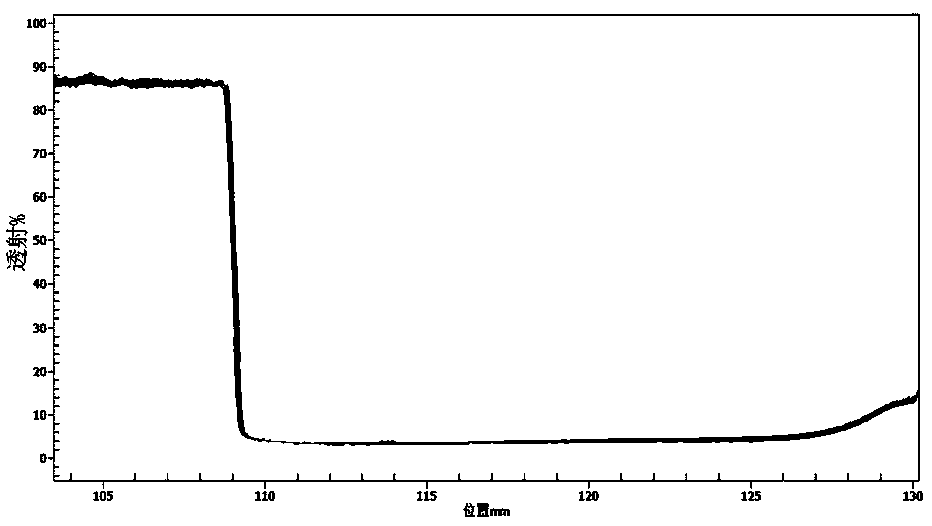

Image

Examples

Embodiment 1

[0029] Myofibrillar protein and food grade xanthan gum were dissolved in deionized water respectively, stirred for 2 h, and the pH of the solution was adjusted to 5.0 with HCl solution with a total acid concentration of 0.1 mol / L to obtain protein stock solution and xanthan gum stock solution respectively. solution, the protein stock solution is added to the xanthan gum stock solution and mixed evenly to obtain a mixed solution, the total mass concentration of myofibrillar protein and xanthan gum in the control mixed solution is 1%, the quality of myofibrillar protein and xanthan gum The ratio is 4:1; 0.05 g / 100 mL of vitamin E is dissolved in soybean oil and added to the mixed solution, the amount of soybean oil added is controlled to be 20% of the mass of the mixed solution, stirred for 2 h, and high-speed sheared at 12000 rpm Disperse for 1 min, and then homogenize under high pressure at 80 Mpa for 3 times to obtain myofibrillar protein / xanthan gum composite emulsion rich in...

Embodiment 2

[0032] Dissolve myofibrillar protein and food-grade xanthan gum in deionized water respectively, stir for 3 hours, adjust the pH of the solution to 3.0 with HCl solution with a total acid concentration of 0.1mol / L, and obtain protein stock solution and xanthan gum stock solution respectively , adding the protein stock solution to the xanthan gum stock solution and mixing uniformly to obtain a mixed solution, controlling the total mass concentration of myofibrillar protein and xanthan gum in the mixed solution to be 1%, and the mass ratio of myofibrillar protein to xanthan gum 1:1; 0.05 g / 100 mL of vitamin E was dissolved in soybean oil and added to the mixed solution, the amount of soybean oil added was controlled to be 10% of the mass of the mixed solution, stirred for 2 h, and dispersed under high-speed shear at 18000 rpm 2 min, and then homogenized under high pressure at 120 Mpa for 3 times to obtain myofibrillar protein / xanthan gum composite emulsion rich in functional fact...

Embodiment 3

[0035] Myofibrillar protein and food grade xanthan gum were dissolved in deionized water respectively, stirred for 2 h, and the pH of the solution was adjusted to 4.0 with HCl solution with a total acid concentration of 0.1 mol / L to obtain protein stock solution and xanthan gum stock solution respectively. solution, the protein stock solution is added to the xanthan gum stock solution and mixed evenly to obtain a mixed solution, the total mass concentration of myofibrillar protein and xanthan gum is controlled to be 1% in the mixed solution, and the quality of myofibrillar protein and xanthan gum is The ratio is 2:1; 0.04g / 100 mL of vitamin E is dissolved in soybean oil and added to the mixed solution, the amount of soybean oil added is controlled to be 10% of the mass of the mixed solution, stirred for 2 h, and sheared at a high speed of 15000rpm Disperse for 1 min, and then homogenize under high pressure at 100 Mpa for 5 times to obtain myofibrillar protein / xanthan gum compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com