Gradient sodium ion doped nickel cobalt lithium aluminate positive electrode material, preparation method and lithium battery

A technology of nickel-cobalt-lithium-aluminate and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as capacity decline, and achieve the effect of improving layered structure, simple and efficient doping process, and improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

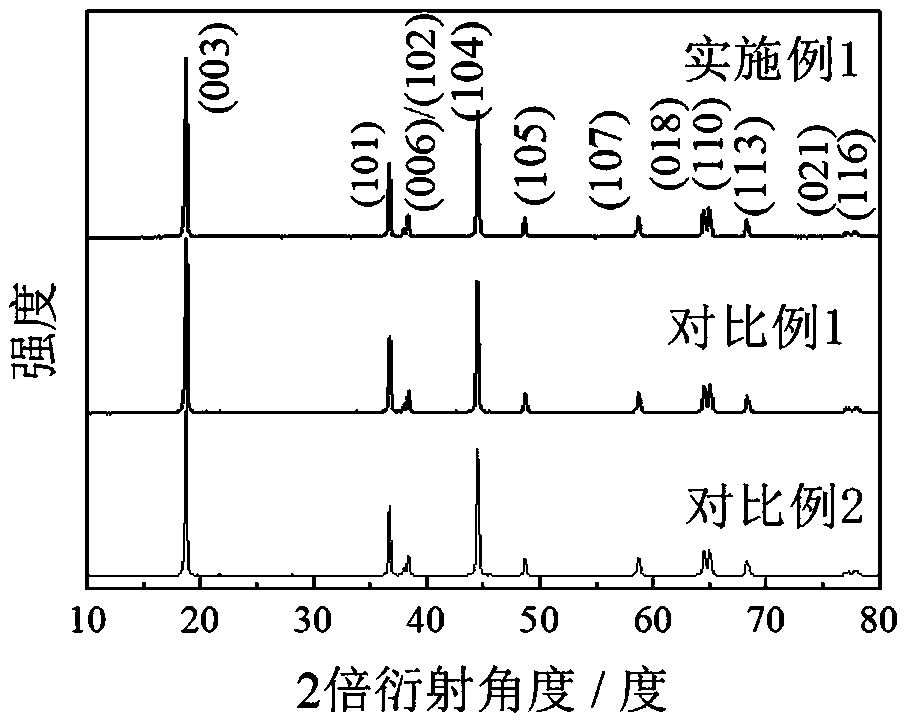

Embodiment 1

[0033] Gradient Na + The preparation of doped nickel cobalt lithium aluminate, concrete steps are as follows:

[0034] Weigh 4.5571 grams of precursor Ni 0.8 co 0.15 Al 0.05 (OH) 2 , 1.9396 g Li 2 CO 3 (Excessive Li to make up for lithium loss during high-temperature calcination) and 0.048 g of NaCl, after mixing the three thoroughly, the temperature of the material was raised to 450 °C at a rate of 3 °C / min in an oxygen atmosphere in a tube furnace C for 6 hours, then raised the temperature to 850°C for 12 hours at a heating rate of 3°C / min, and finally cooled to room temperature to obtain a gradient Na + doped LiNi 0.8 co 0.15 Al 0.05 o 2 .

[0035] The prepared positive electrode material is used to make the electrode sheet and assemble the battery. The process is as follows:

[0036] (1) Production of electrode sheets

[0037] The positive electrode material prepared in Example 1 was uniformly mixed with the conductive agent and the binder according to the mas...

Embodiment 2

[0058] Gradient Na + The preparation of doped nickel cobalt lithium aluminate, concrete steps are as follows:

[0059] Weigh 4.5571 grams of precursor Ni 0.8 co 0.15 Al 0.05 (OH) 2 , 1.85 g Li 2 CO 3 and 0.065 gram of NaCl, after the three are fully mixed, the material is pre-fired at 450 °C for 6 hours under an oxygen atmosphere in a tube furnace with a heating rate of 3 °C / min, and then heated at 3 °C The heating rate of / min raised the temperature to 800 ° C for 12 hours, and finally cooled to room temperature to obtain the gradient Na + doped LiNi 0.8 co 0.15 Al 0.05 o 2 .

[0060] The prepared positive electrode material was used to make electrode sheets and assemble batteries, the steps were the same as in Example 1.

Embodiment 3

[0062] Gradient Na + The preparation of doped nickel cobalt lithium aluminate, concrete steps are as follows:

[0063] Weigh 4.5571 grams of precursor Ni 0.8 co 0.15 Al 0.05 (OH)2 , 2.035 g Li 2 CO 3 and 0.204 gram of NaCl, after the three are fully mixed, the material is pre-fired at 450 °C for 6 hours at a rate of 3 °C / min in an oxygen atmosphere in a tube furnace, and then heated at 3 °C The heating rate of / min raised the temperature to 850 ° C for 10 hours, and finally cooled to room temperature to obtain the gradient Na + doped LiNi 0.8 co 0.15 al 0.05 o 2 .

[0064] The prepared positive electrode material was used to make electrode sheets and assemble batteries, the steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com